Radial sliding bearing for turbine drill

A technology of radial sliding and turbo drilling tools, applied in the field of downhole power drilling tools and radial sliding bearings, can solve the problems of high equipment maintenance cost, large mechanical friction loss, low efficiency, etc., and achieve good bearing and anti-wear ability, The effect of preventing the bearing temperature from being too high and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

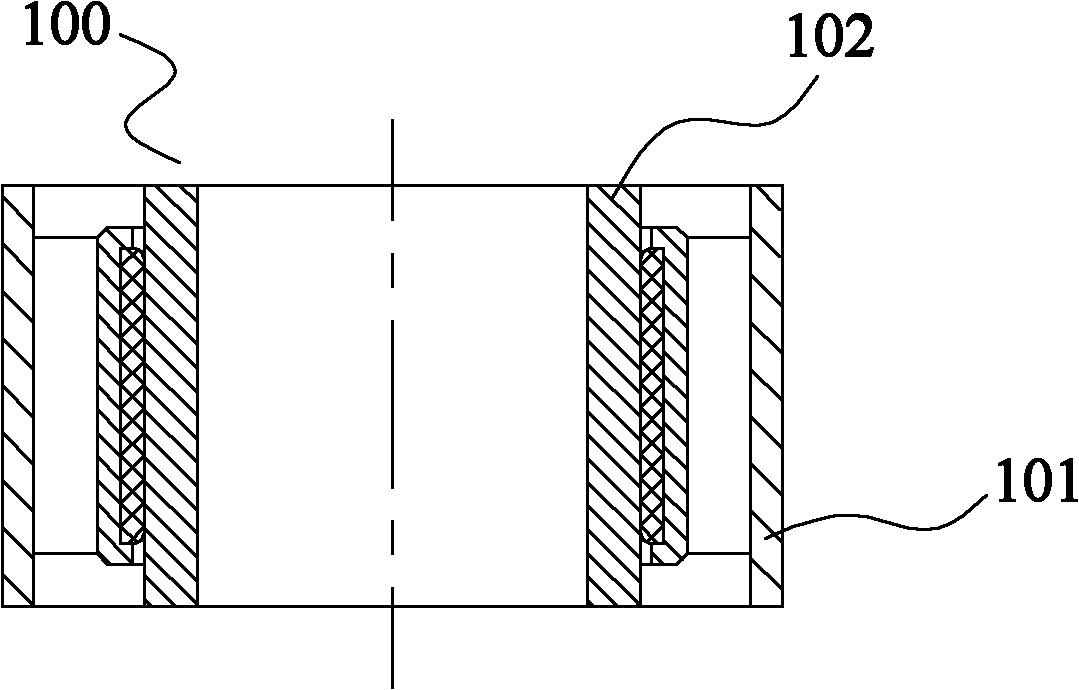

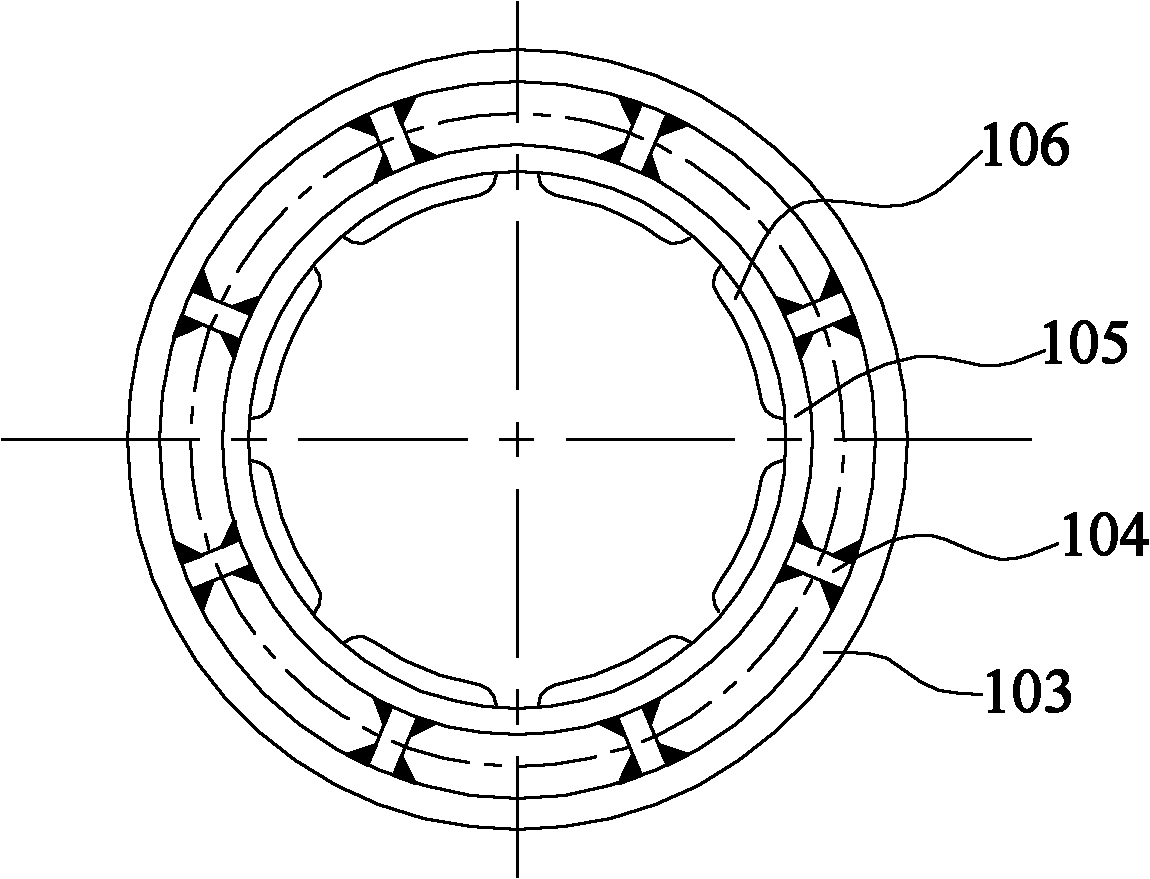

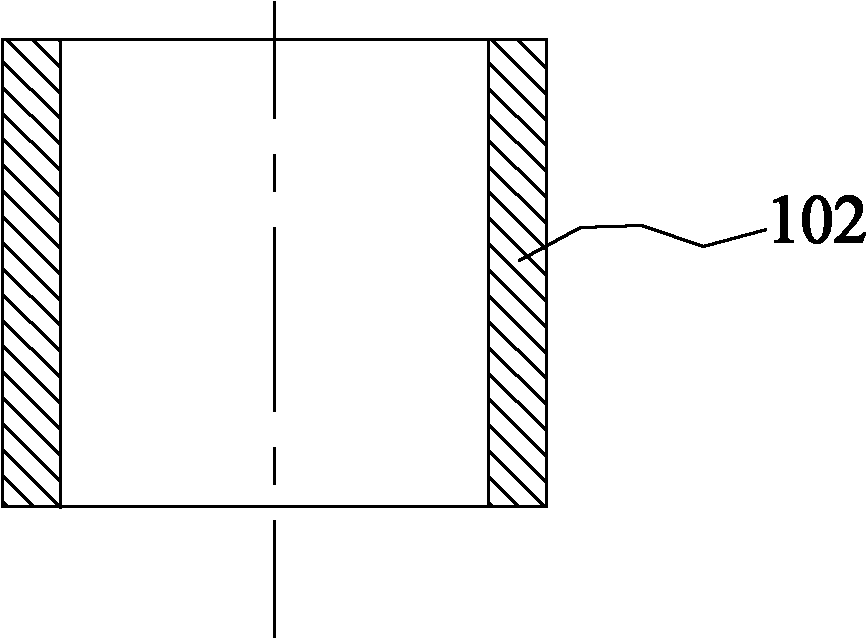

[0048] Please refer to Figure 4 to Figure 6 , are respectively the schematic cross-sectional structural diagram of the first embodiment of the radial sliding bearing used in the turbodrilling tool of the present invention; the top view structural schematic diagram of the stationary ring of the first embodiment of the present invention; and the cross-sectional view of the moving ring of the first embodiment of the present invention Schematic view of the structure. As shown in the figure, the present invention proposes a radial sliding bearing for a turbodrill, including a steel static ring 1 (ie, the outer ring) and a steel dynamic ring 2 (ie, the inner ring), the static ring 1 Set on the outside of the moving ring 2, the inner surface of the static ring 1 is inlaid with a first sliding contact layer 4, the first sliding contact layer 4 is composed of several cemented carbide blocks 41 arranged at intervals; The outer surface of the moving ring 2 is inlaid with a second slidi...

Embodiment 2

[0057] Please refer to Figure 7 to Figure 9 , are respectively the schematic cross-sectional structure diagram of the second embodiment of the present invention; the top view structural schematic diagram of the moving ring of the second embodiment of the present invention; the cross-sectional structural schematic diagram of the static ring of the second embodiment of the present invention.

[0058] As shown in the figure, the structure and function of this embodiment are basically the same as those of the first embodiment above, so the same components are denoted by the same reference numerals and will not be described again. The difference between this embodiment and the above-mentioned first embodiment is that a plurality of penetrating working fluid passages 3 are provided between the outer surface and the inner surface of the moving ring 2 in the axial direction, and the plurality of working fluid passages 3 are evenly arranged along the circumferential direction of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com