C/SiC composite material surface oxidation-resistant coating and method for making same

An anti-oxidation coating and composite material technology, applied in metal material coating technology, coating, gaseous chemical plating, etc., can solve the problem of limited anti-oxidation effect, low effective service life of coating, and anti-oxidation protection effect of coating problems such as weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

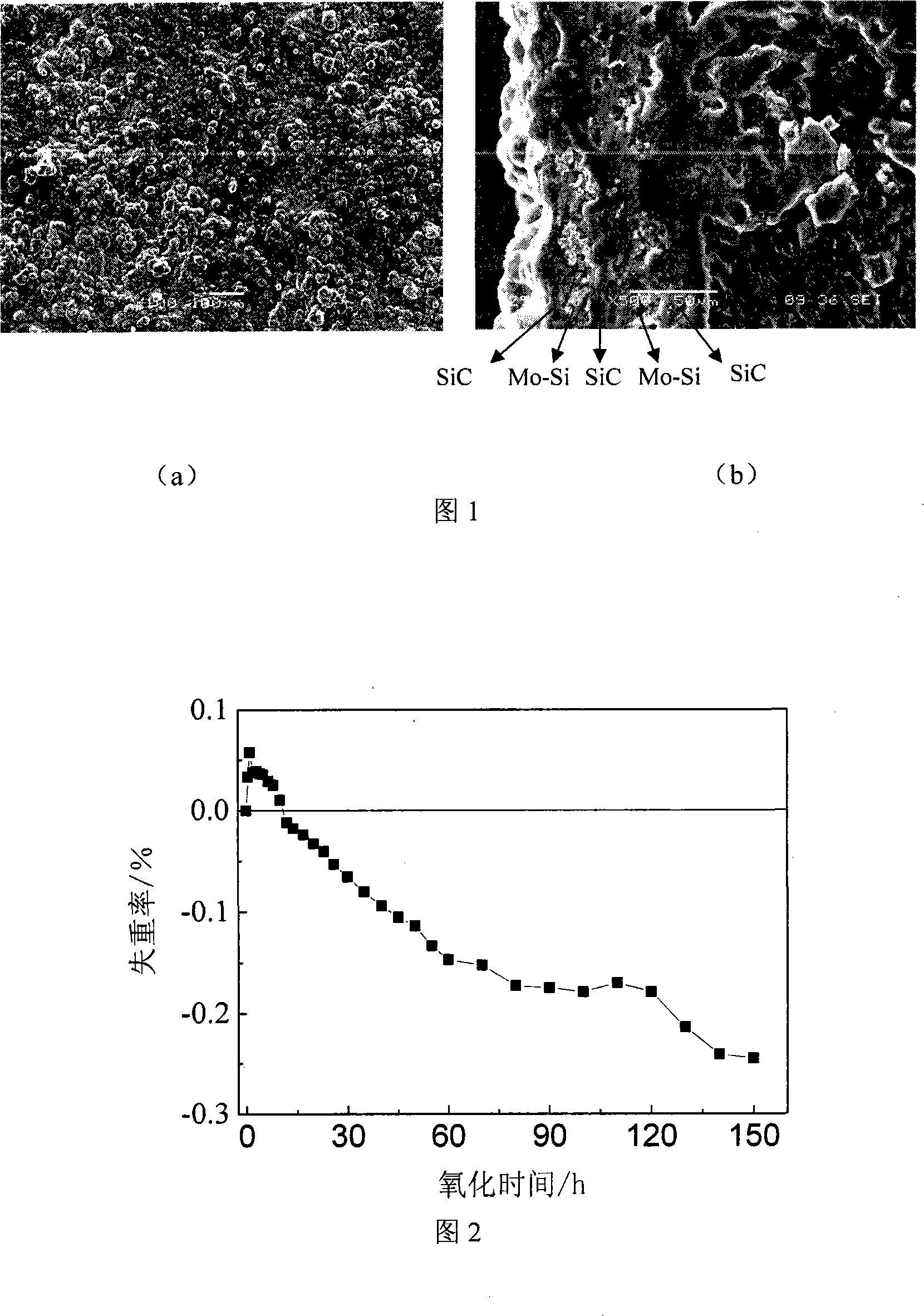

Embodiment 1

[0029] The preparation process and process parameters are as follows: the surface of the C / SiC composite material prepared by the MSI or CVI process is ground and polished, and the size after grinding and polishing is 20×20×5 mm, then ultrasonically cleaned, and dried for use; (1) the above The treated composite is placed in a CVD furnace. Use MTS as the silicon source, use a constant temperature water bath, and keep the temperature of MTS at any temperature between 28-35°C; use Ar as the dilution gas (flow rate is 200-300ml / min), 2 As the carrier gas, MTS was brought into the CVD furnace by bubbling to prepare SiC coating. Process parameters: the deposition pressure is 200-250Pa, the deposition temperature is 1050-1150°C, and the molar ratio in the step (1) is H 2 / MTS=(8~10) / 1, deposition time 5~7h; (2) Si powder (300~400 mesh), Mo powder (400~550 mesh) and silica sol (chemically pure) are used as raw materials. According to Si powder: Mo powder: silica sol mass ratio 30~4...

Embodiment 2

[0034] The preparation process and process parameters are as follows: the surface of the composite material prepared by the MSI process is ground and polished, and the size is 40 × 5 × 3 mm after grinding and polishing, and then ultrasonically cleaned and dried for use; other steps are the same as in Example 1.

[0035] In an open silicon-molybdenum rod furnace, heat up to 1400°C. After the temperature is stable, put the coating sample in the furnace, oxidize it for 5 minutes, and quickly put it into a constant temperature water bath at 100°C to quickly cool down to 100°C. After drying, weigh it . Repeat the above thermal shock process. The cumulative times of thermal shocks were 25 and 50 respectively.

[0036] The thermal shock results of the prepared coating samples at 1400°C100°C are as follows:

[0037] During the thermal shock process of the coating sample, the coating remains intact without falling off or falling off. After 25 thermal shocks and 50 thermal shocks, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com