Method for preparing astragaloside iv by enzymic hydrolysis for astragalus saponin glycosyl

A technology of astragaloside IV and astragaloside, which is applied in the field of enzymatically hydrolyzing astragaloside glycosides to prepare astragaloside IV, can solve the problems of low content of astragaloside IV, overcome the destructiveness of saponins, improve the extraction rate, and have strong purpose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

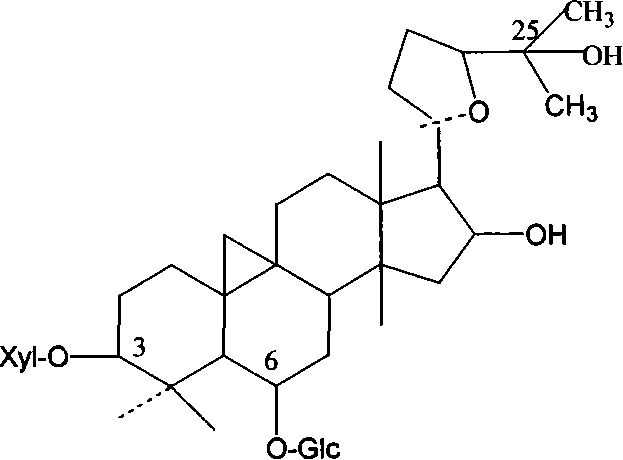

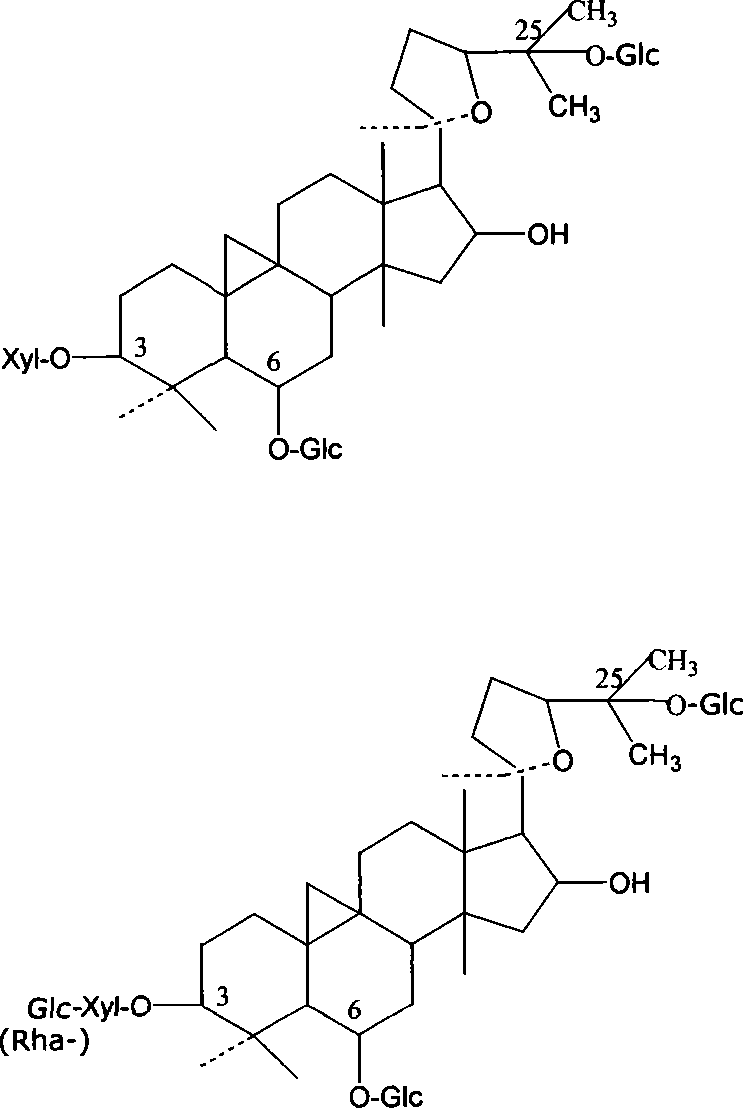

Image

Examples

Embodiment 1

[0015] a. Aspergillus niger (Aspegillus niger) was cultured with agitation and ventilation at a temperature of 28-30°C for 50-100 hours in a medium containing 5% malt water extract and 1% enzyme-producing inducer-Astragalus water extract , centrifuged and sterilized to get the supernatant (containing enzyme mixture), in the supernatant, use 60-75% saturated ammonium sulfate to precipitate the enzyme protein, collect the protein, and dissolve it in acetic acid buffer commonly used in 1 / 10 of the fermentation broth volume. Solution (0.02M, pH 5.0), or phosphate buffer, Tris buffer, dialyzed to remove ammonium sulfate, centrifuged to remove slag, which is the enzyme solution;

[0016] b. Mix 50 ml of the above enzyme solution, 3 g of astragaloside and 100 ml of acetic acid buffer (0.02M, pH 5.0), react at a temperature of 20-55°C for 6-24 hours, and then add 1 / 3 volume of The saponins were extracted three times with n-butanol, and evaporated to dryness under reduced pressure to o...

Embodiment 2

[0019] a. Aspergillus oryzae in water containing 5% wheat bran water extract, 0.02% enzyme-producing inducer-soybean isoflavone or rutin containing flavonoids, or 0.6% of its flavonoid source plant-Sophora japonica In the culture medium of the extract, under the condition of a temperature of 28-30°C, agitate and ventilate for 50-100 hours, centrifuge and sterilize to obtain a supernatant (containing an enzyme mixture), and use 60-75% saturation of the supernatant in the supernatant Ammonium sulfate precipitates enzyme protein, collects protein, dissolves in commonly used acetate buffer (0.02M, pH 5.0), or phosphate buffer, Tris buffer of 1 / 10 of the fermentation broth volume, dialyzes to remove ammonium sulfate, centrifuges to remove slag , which is the enzyme solution;

[0020] b. Treat astragaloside with enzyme liquid according to the method of Example 1, purify and detect the result of the enzyme reaction product: the product is mainly astragaloside IV, and the conversion r...

Embodiment 3

[0023] Use the method of Example 1 or Example 2 to prepare 40 ml of enzyme liquid, add it to 10 grams of Astragalus slices or powder, soak the Astragalus slices at a temperature of 35-40°C for 4-40 hours, dry the Astragalus slices, and use high-efficiency liquid Phase chromatography (document 7) measures the content of astragaloside IV in Huangqi tablets, which is more than 6 times higher than that in the original Huangqi tablets or powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com