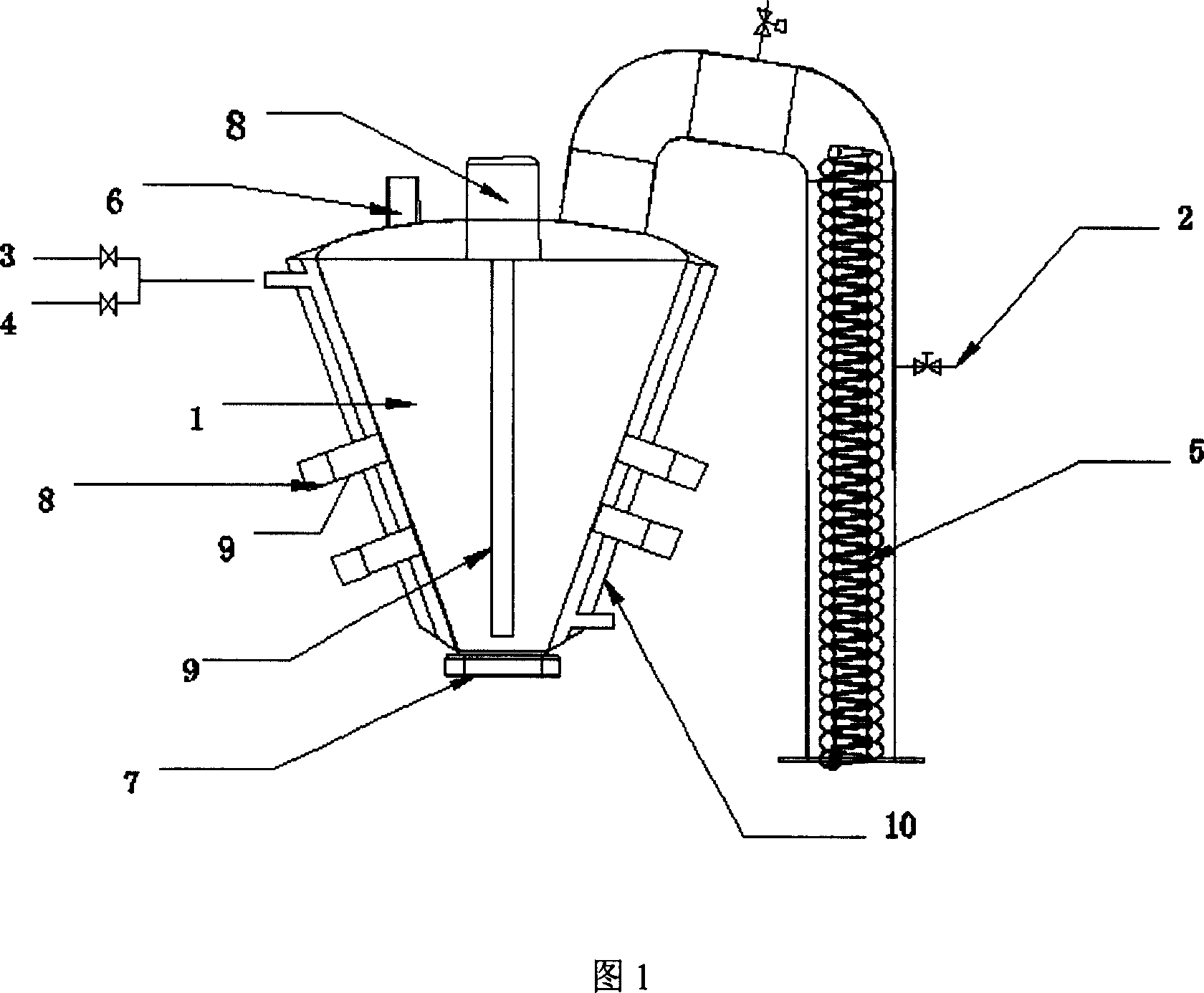

Supersonic freeze drying method and apparatus

A drying method, ultrasonic freezing technology, applied in drying solid materials, lighting and heating equipment, drying solid materials without heating, etc., can solve the problems of prolonged drying time, large difference in evaporation speed, and increased cost, and achieve the goal of promoting heat Effects of conversion, reduction of heat transfer resistance, and shortening of freeze-drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Red ginseng water reflux extraction, the first time 5 times the amount of water, 1 hour; the second time 3 times the amount of water, 0.5 hours; the third time 3 times the amount of water, 0.5 hours; combine the extracts, let cool, dilute hydrochloric acid to adjust the pH 2, filter, polyamide on the supernatant, rinse with water, the effluent is colorless; elute with dilute alkaline solution, collect the eluate, adjust the pH to 5 with dilute hydrochloric acid, apply macroporous resin on the acid solution, rinse with water, and use 95% ethanol For elution, collect the alcohol eluate, concentrate under reduced pressure to a solid content of 10-30% (weight), and set aside. Add an appropriate amount of mannitol and transfer to an ultrasonic freeze dryer. Under continuous ultrasound, the frequency is 15kHz, and the material is frozen; cryogenically cooled to a temperature of -40°C, kept for 4 hours, turned on a vacuum of 0.3mbar, started the condenser, and performed a temp...

Embodiment 2

[0030] Astragalus is extracted three times with water, add 5, 4, and 4 times the amount of water, each time for 1 hour, let it cool, concentrate the reverse osmosis membrane to a relative density of 1.06 (with the density of water at 20°C as a reference), and concentrate under reduced pressure to a relative density of 1.06. Density 1.1-1.15, add 95% ethanol to make alcohol concentration to 70% (volume ratio), stand still for 12 hours, filter, supernatant is concentrated to relative density 1.15-1.20, add 95% ethanol to make alcohol concentration to 85%, static Leave it for 24 hours, filter, concentrate the supernatant to a relative density of 1.2-1.25, add 8 times the amount of water for ultrasound, place it below 15°C for 24 hours, filter, concentrate the supernatant under reduced pressure to a relative density of 1.10-1.15, add an appropriate amount of mannitol , into an ultrasonic freeze dryer. Under continuous ultrasound, the frequency is 5kHz, and the material is frozen; ...

Embodiment 3

[0032]Sanqi plus 75% ethanol reflux extraction 3 times, the first time 5 times the amount of water, 1 hour; the second time 4 times the amount of water, 0.5 hours; the third time 4 times the amount of water, 0.5 hours; combined extracts, reduced pressure Concentrate without alcohol smell, apply macroporous adsorption resin, wash with water, elute with 75% ethanol, collect the eluate, and set aside; apply 941 decolorizing resin to the eluate, collect the effluent, and concentrate under reduced pressure to powder. Dissolve the powder with an appropriate amount of ethanol, slowly drop it into the aqueous solution of hydroxypropyl β-cyclodextrin under ultrasound, concentrate under reduced pressure to a relative density of 1.10-1.15, and introduce the drug solution into an ultrasonic freeze dryer. Under continuous ultrasound, the frequency is 10-15kHz, and the material is frozen; cryogenically cooled to a temperature of -50°C, kept for 4 hours, turned on a vacuum of 3mbar, started t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com