Adjustable self-flowing diffluence type ring-shape oxidization trench

An adjustable and split-flow technology, applied in the field of sewage treatment, can solve the problems of insufficient flexibility and adaptability of movable diversion walls, failure to find and reduce the degree of turbulence in the mixing zone, etc., so as to improve the biological denitrification and phosphorus removal. Effects, overcoming length and angle settings, effects for easy adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

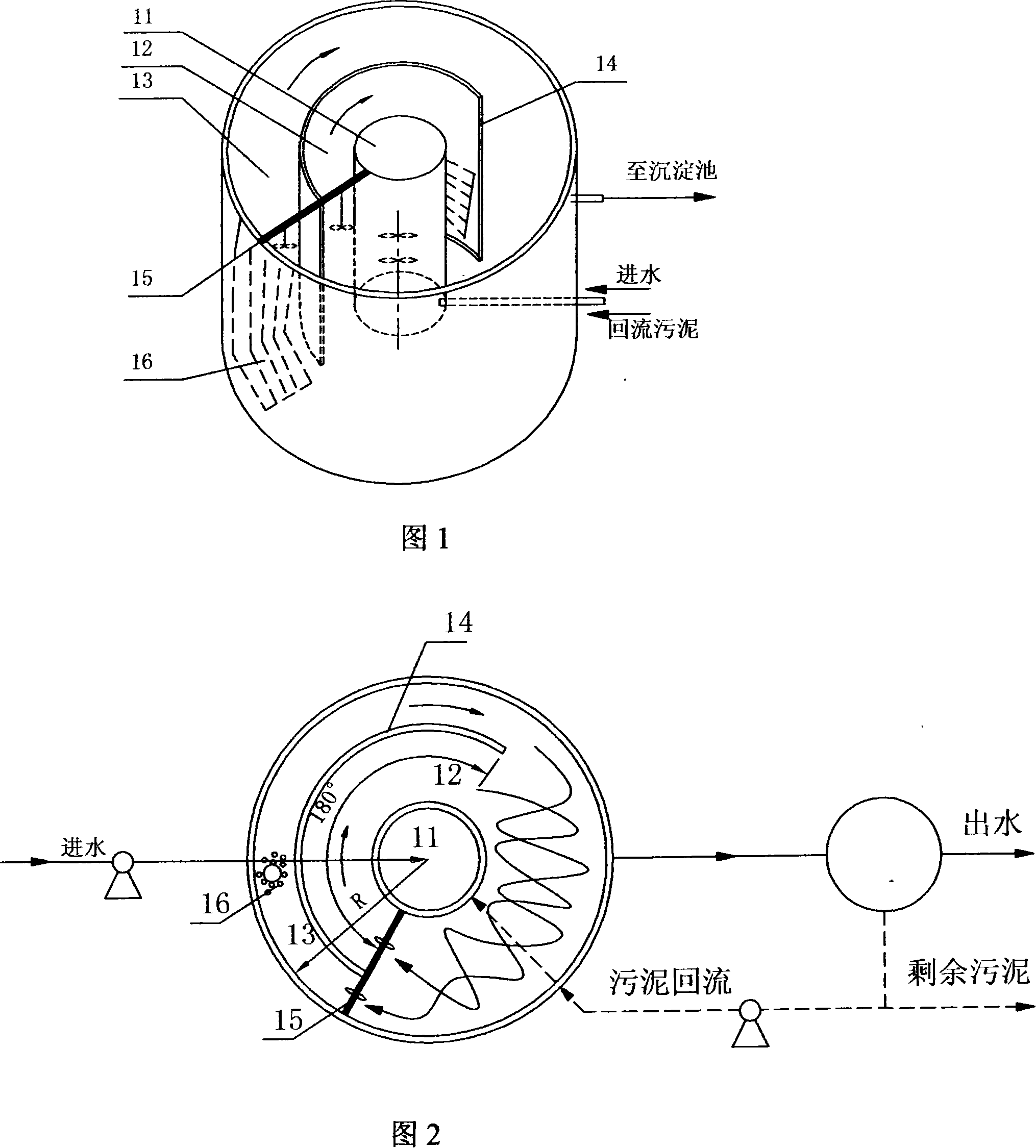

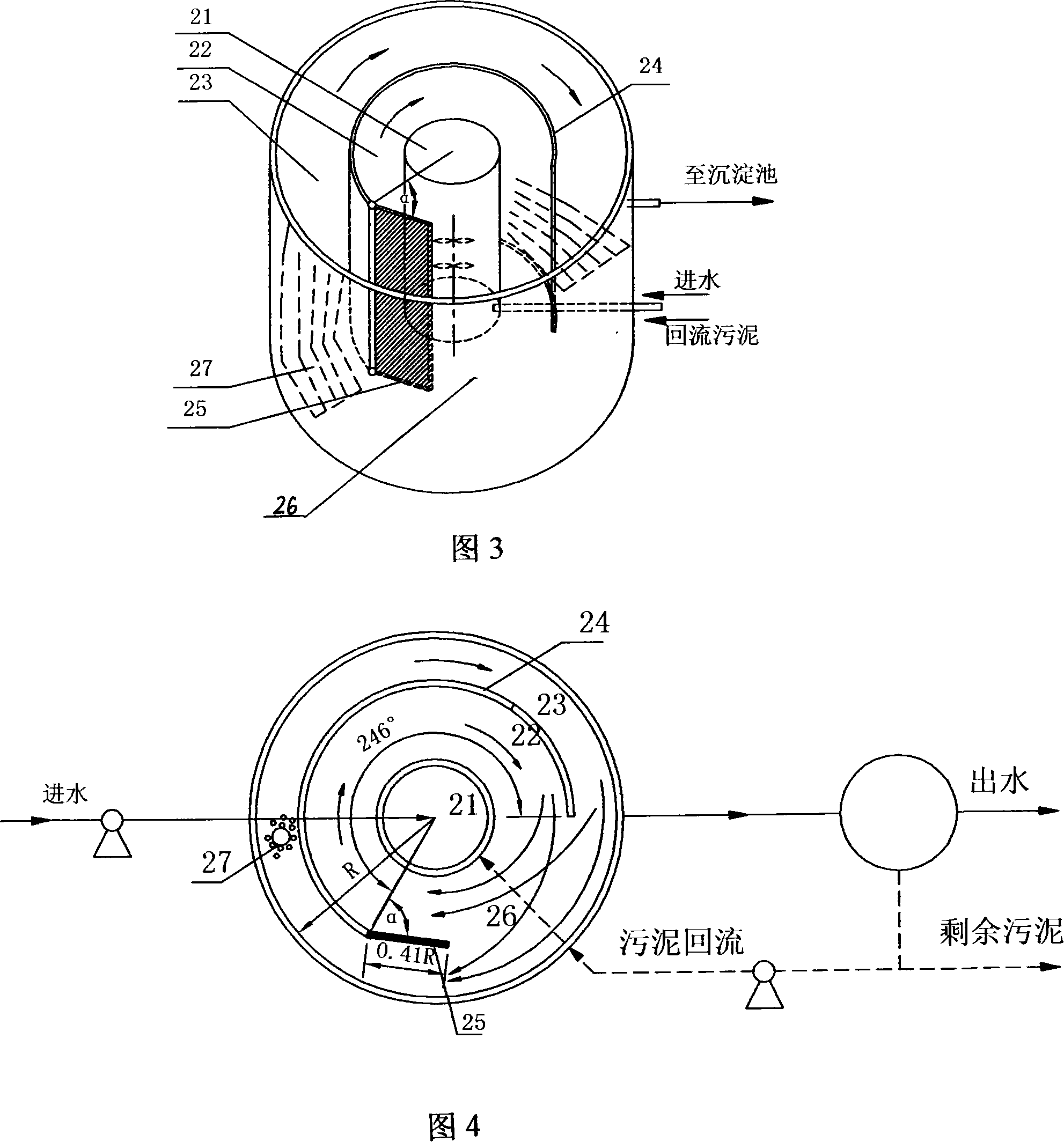

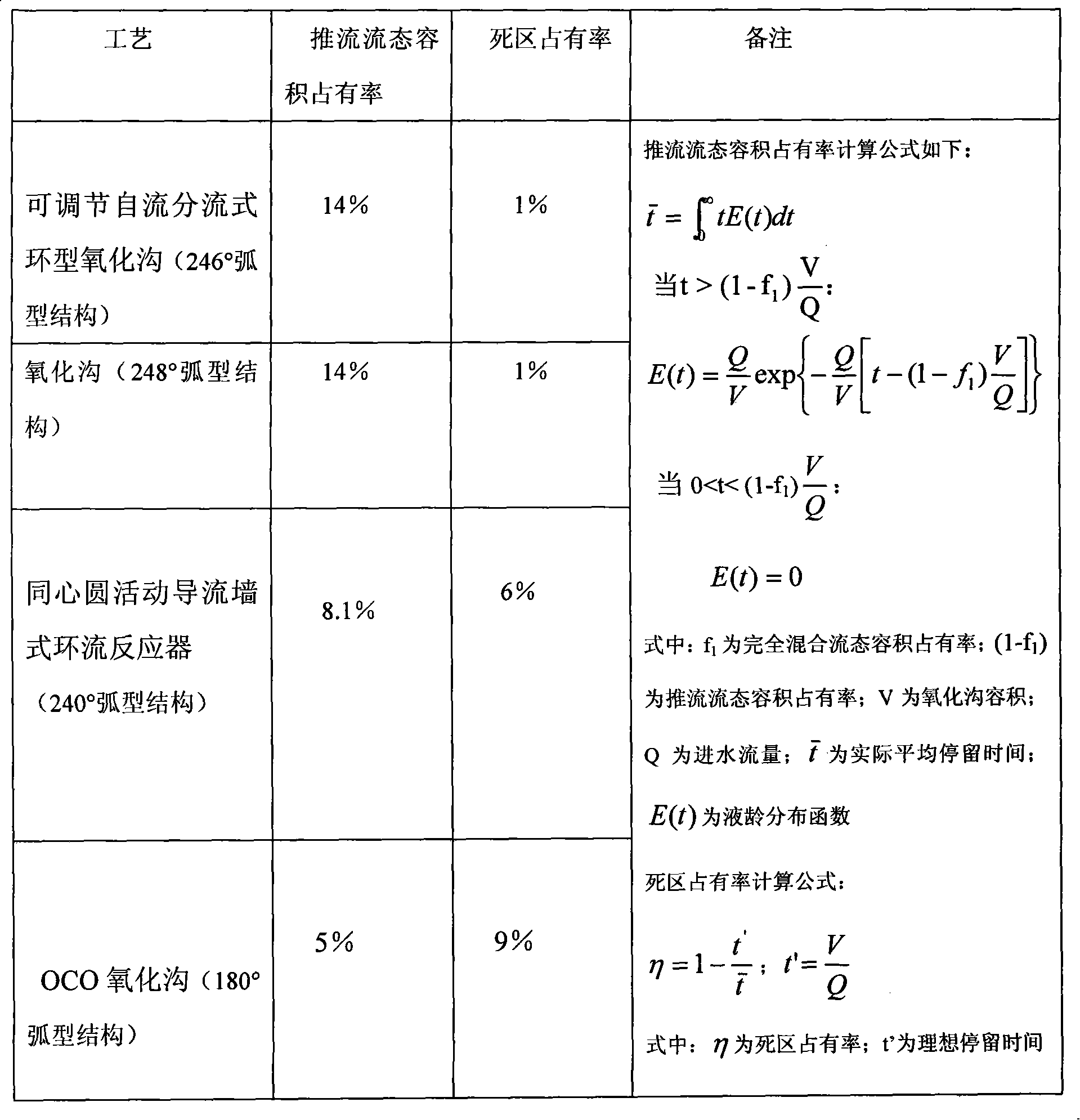

[0025] Referring to Fig. 3 and Fig. 4, the adjustable artesian diversion annular oxidation ditch process consists of three parts: anaerobic zone 21, anoxic zone 22 and aerobic zone 23. The arc of the C-shaped arc partition wall 24 in the middle anoxic zone is 246° (as shown in FIG. 3 and FIG. 4 ). Combining Figures 1 and 2, it can be seen that compared with the middle C partition wall 14 of the OCO oxidation ditch, the arc is increased by 66 degrees, and the arc is also larger than the corresponding arc of the concentric movable diversion wall type loop reactor. Referring to Fig. 3 and Fig. 4, the adjustable artesian diversion wall 25 is set at the starting end of the C-shaped arc partition wall 24 in the adjustable self-flow diversion type annular oxidation ditch anoxic zone, and the length of this diversion wall extending into the mixing zone 26 is 0.41R (R is the radius of the outermost ring shape of the oxidation ditch), and the rotation angle around the starting point of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com