Method for degrading dyeing waste water by using cerium oxide nano particle as catalyst

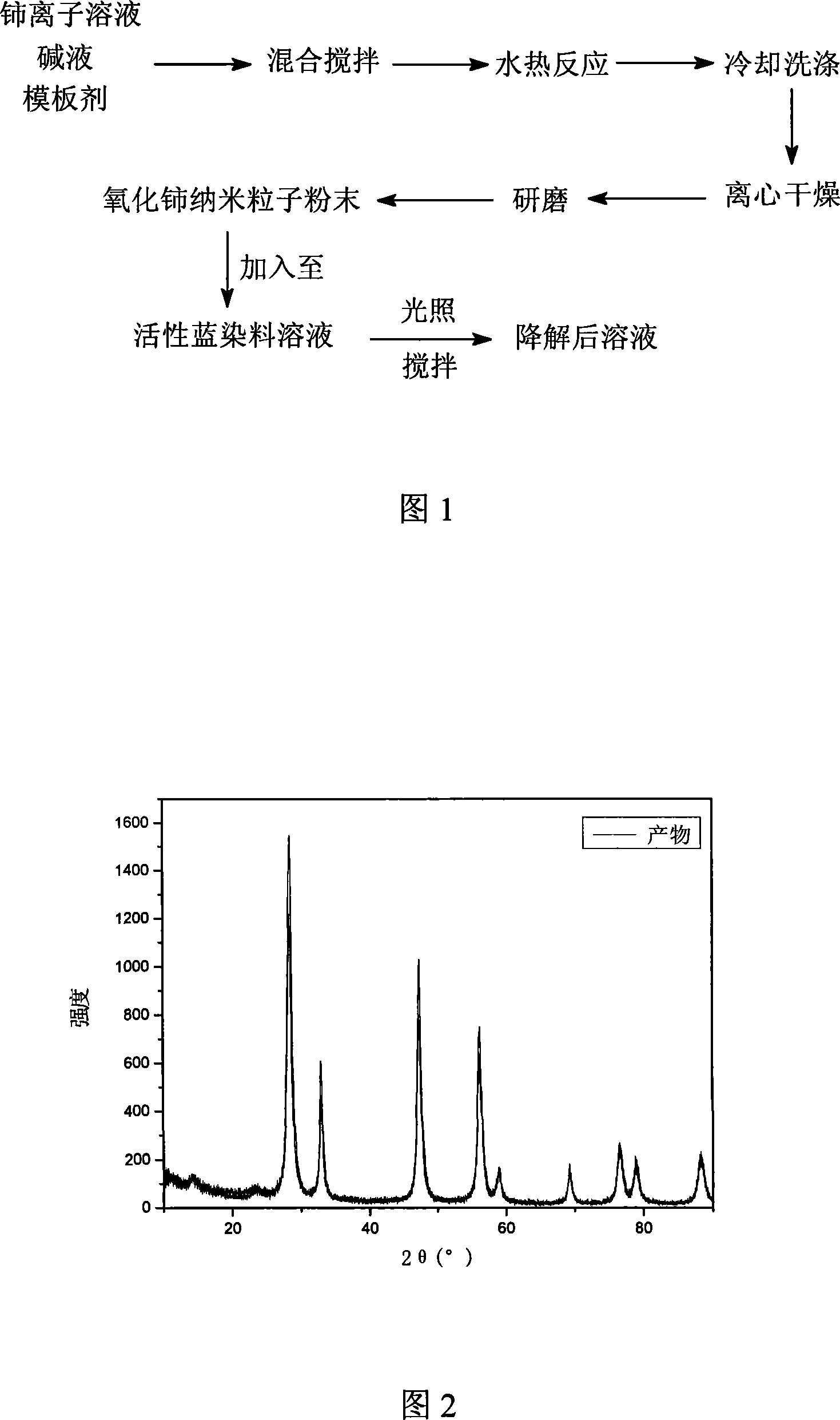

A nanoparticle and dye wastewater technology, applied in the application field of cerium oxide nanoparticles, can solve the problems of complex catalyst preparation process, harsh degradation conditions, insufficient light utilization, etc., and achieves fast degradation speed, easy control of conditions, and energy saving. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare 0.1mol / L Ce(NO 3 ) 3 solution and 0.4mol / L NaAc solution, take 10ml of 0.1mol / LCe (NO 3 ) 3 The solution was put into a beaker, 2.73 g CTAB was added and stirred, and then 10 ml of 0.4 mol / L NaAc solution was added, and the mixture was mixed and stirred. Then, the mixed solution was put into a high-pressure polytetrafluoroethylene reaction tank, reacted in an oven at 180° C. for 6 hours, and cooled to room temperature in the furnace. The reacted solution was taken out, washed three times with deionized water and absolute ethanol, centrifuged, dried and ground to obtain cerium oxide nanoparticle powder. Prepare 100 mg / L reactive blue solution, put 40 ml into a conical flask, add the prepared cerium oxide nanoparticle powder, stir under natural light for 5 hours, and centrifuge to obtain a degraded solution.

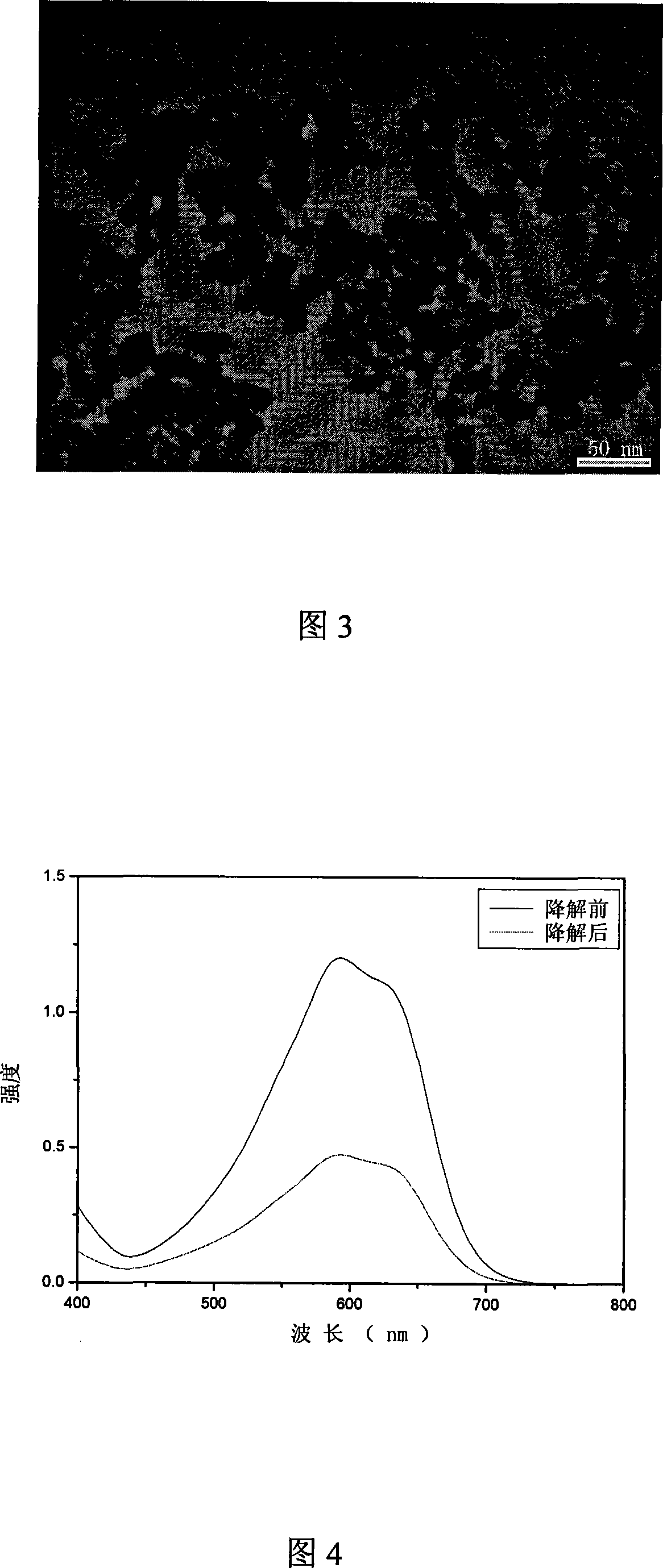

[0021] The obtained cerium oxide nanoparticle powder was subjected to X-ray diffraction analysis. The results are shown in Figure 2. The diffraction pea...

Embodiment 2

[0025] Using the same reactants and methods as in Example 1, and reacting in an oven at 150 °C for 24 hours, CeO with a particle size in the nanometer scale can also be prepared. 2 Powder, degradable reactive blue dye wastewater.

Embodiment 3

[0027] with Ce(Ac) 3 and H 2 O is a reactant. Using the same conditions and methods as in Example 1, CeO with a particle size in nanometers can also be prepared. 2 Powder, degradable reactive blue dye wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com