Method for preparing porous titanium filtering material surface functionalization nano-structure film

A technology of surface functionalization and filtering materials, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems such as surface modification reports of porous structure titanium alloy materials, etc., to improve photocatalytic efficiency, diffusion Process reduction, the effect of increasing the filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

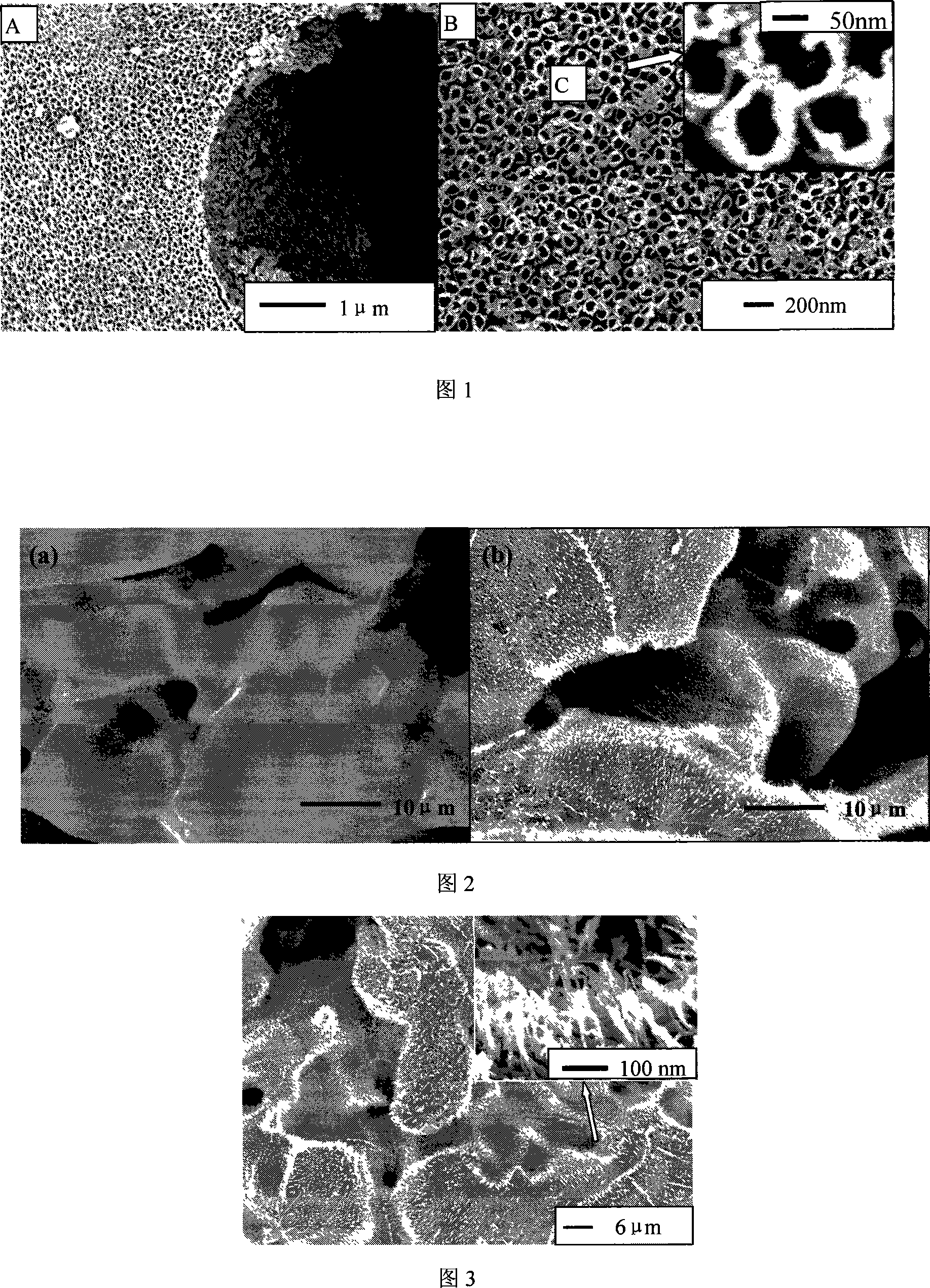

[0024] The industrial porous titanium alloy filter material is cleaned in sequence with ethanol, acetone and deionized water in ultrasonic, and dried in a hot air oven at 70°C to 80°C. At room temperature, the platinum sheet is used as the counter electrode (cathode), and the porous titanium alloy filter material is used as the anode; the 1M (NH 4 ) 2 SO 4 with 0.5wt% NH 4 F is the electrolyte, in the state of magneton stirring, an external voltage of 20V is applied, and the electrochemical reaction 2H is carried out. The oxidized porous titanium alloy filter material is washed several times until there is no F- and other ions except Ti cations on the surface and in the pores, and then dried at room temperature and placed in a hot air drying oven at 70°C to 80°C for 1 hour. The morphology of the titanium oxide nanotube array prepared by this process is shown in Fig. 1 .

Embodiment 2

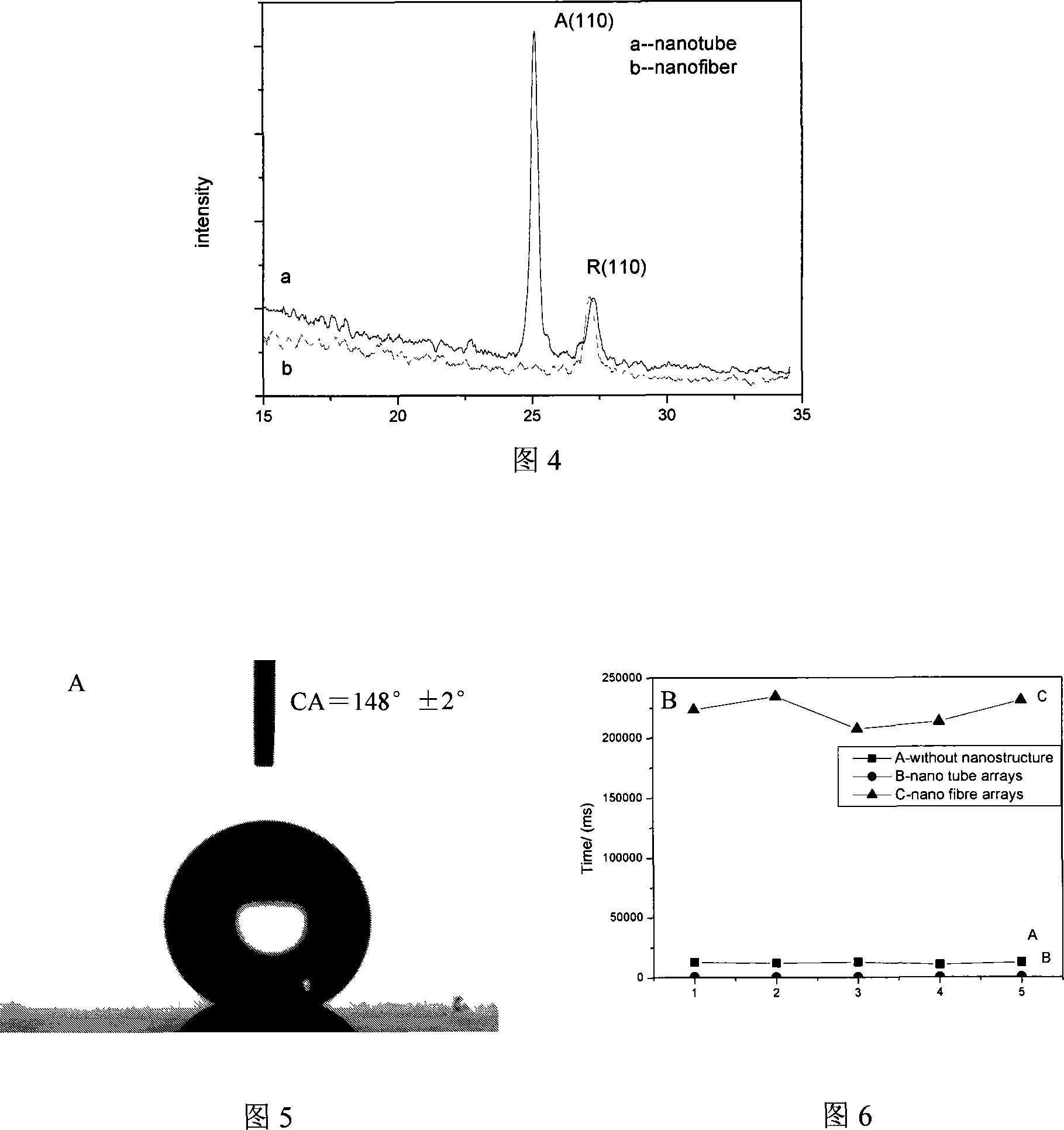

[0026] The porous titanium alloy filter material is processed into a sample of 100×10×1mm by mechanical processing. After pretreatment, the applied voltage is 30V, and the volume ratio of ethylene glycol is 97%, and the volume ratio of water is 2.5%. The volume ratio of HF acid is 0.5%, and the anodic oxidation is carried out for 17 hours in the electrolyte solution whose pH value is adjusted to 6. Titanium dioxide nanotube arrays were washed with deionized water several times until there were no fluoride ions in the surface and pores, and no other ions except Ti cations, and placed in a drying oven at 70°C to 80°C for 1 hour. The morphology of the titanium oxide nanotube array prepared by this process is shown in Fig. 2 .

Embodiment 3

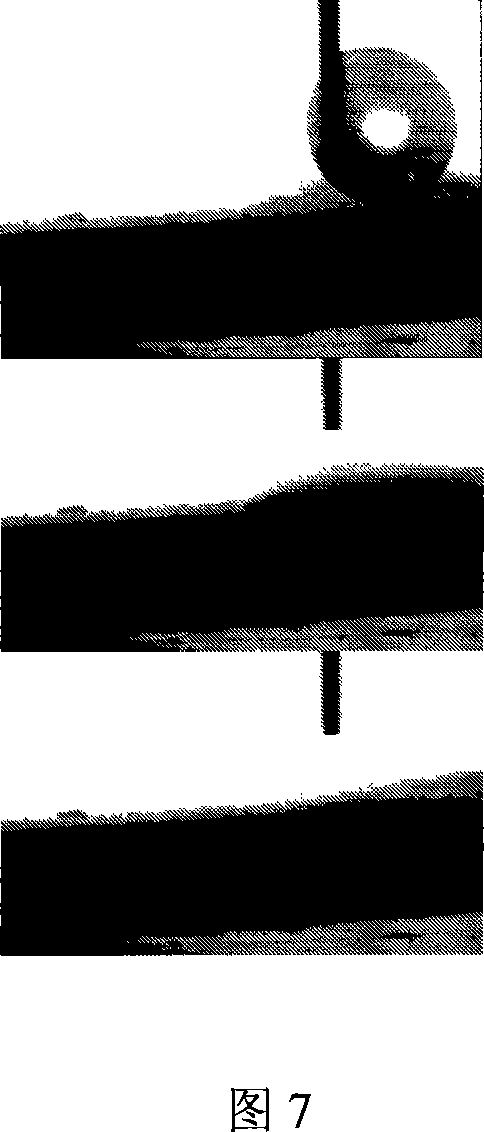

[0028] Process the porous titanium alloy filter material for industrial use into a sample of 100mm×10mm×1mm, clean it with ethanol, acetone and deionized water sequentially in ultrasonic, and dry it in a hot air oven at 70°C to 80°C. At room temperature, the platinum sheet is used as the counter electrode (cathode), and the porous titanium alloy filter material is used as the anode; the 1M (NH 4 ) 2 SO 4 with 0.5wt% NH 4 F is the electrolyte, in the state of magneton stirring, an external voltage of 15V is applied, and the electrochemical reaction is carried out for 25min. The oxidized porous titanium alloy filter material is washed several times until the surface is free of F- and other ions except Ti cations, dried at room temperature, placed in a hot air drying oven, and dried at 70°C to 80°C for 1 hour. The morphology of the titanium oxide nanotube array prepared by this process is shown in Fig. 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com