Low-substituted hydroxypropylcellulose powder and method for producing the same

A hydroxypropyl cellulose, low-substitution technology, applied in the field of low-substituted hydroxypropyl cellulose, can solve the problems of weak compressibility, reduced fiber part weight, reduced compressibility, etc., and achieve excellent compressibility and excellent swelling Performance, the effect of excellent disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

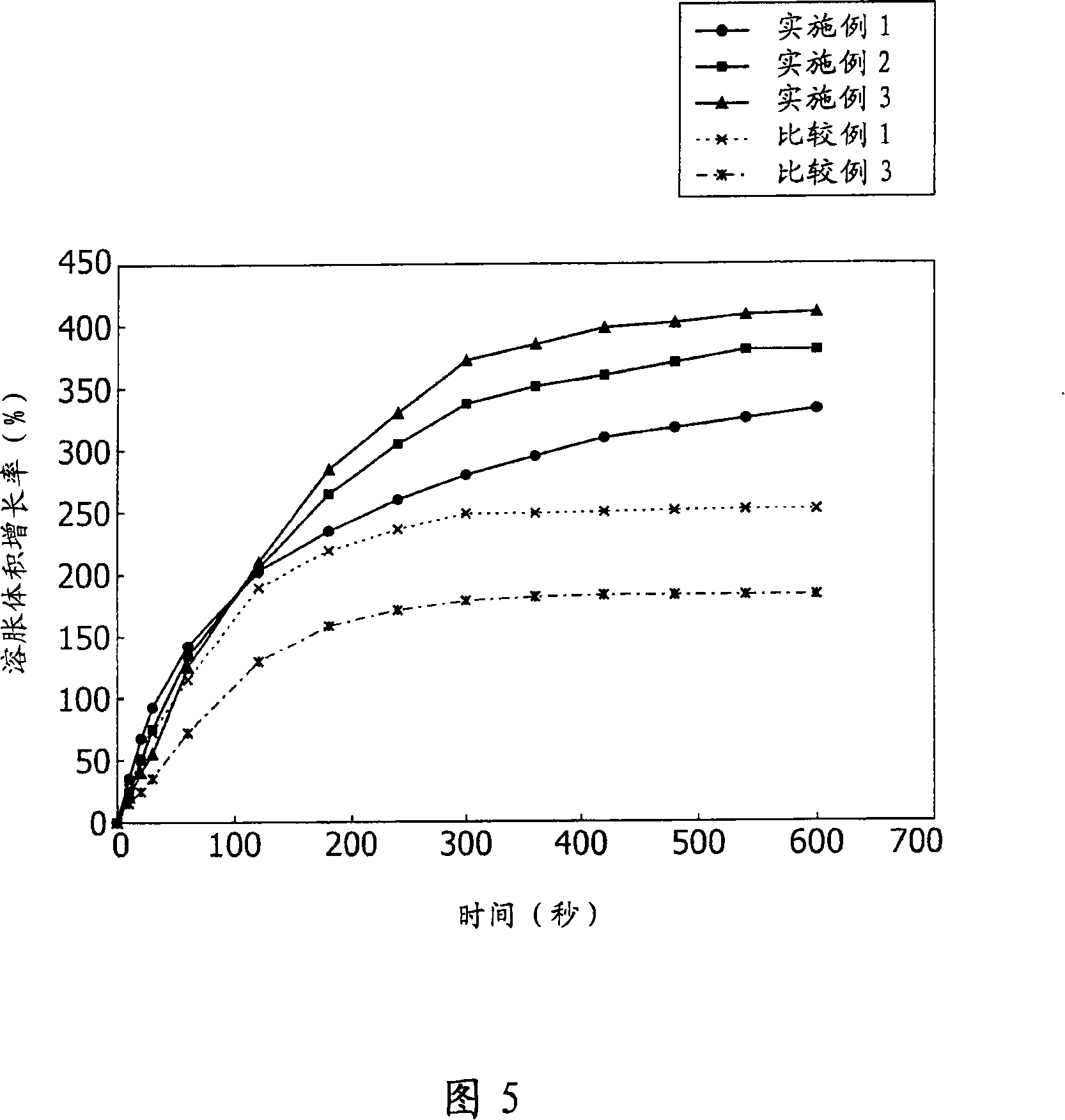

Embodiment 1

[0085] First, 806g of powdery slurry (750g in anhydrous state) was added to a 10L internal stirring reaction device, 303g of sodium hydroxide aqueous solution (26wt%) was added to the reaction device, and then mixed at 45°C for 30 minutes Produce alkaline cellulose, wherein the weight ratio of sodium hydroxide and anhydrous cellulose is 0.105. Nitrogen purging was then carried out, 123 g of propylene oxide (0.164 parts by weight relative to cellulose) was added to the resultant, and then the mixture was reacted for 1.5 hours in a jacket at a temperature of 60° C., thereby obtaining 1232 g of hydroxypropyl fibers Crude reaction product of a prime with a molar substitution of hydroxypropoxy per anhydroglucose unit of 0.28. The etherification reaction rate was 61.4%.

[0086] Then, 236 g of acetic acid (50 wt %) was added to the above-mentioned 10 L internal stirring type reaction apparatus and mixed to perform a neutralization reaction. The neutralized product was washed in ho...

Embodiment 2

[0110] First, 806g of powdered slurry (750g in anhydrous state) was added to a 10L internal stirring reaction device, 504g of sodium hydroxide aqueous solution (26wt%) was added to the reaction device, and then mixed at 45°C for 30 minutes Produce alkaline cellulose, wherein the weight ratio of sodium hydroxide and anhydrous cellulose is 0.175. Nitrogen purging was then carried out, 143 g of propylene oxide (0.190 parts by weight relative to cellulose) was added to the resultant, and the mixture was reacted for 1.5 hours in a jacket at a temperature of 60° C., thereby obtaining 1453 g of hydroxypropyl fibers Crude reaction product of a prime with a molar substitution of hydroxypropoxy per anhydroglucose unit of 0.29. The etherification reaction rate was 53.6%.

[0111] Then, 394 g of acetic acid (50% by weight) was added to and mixed with the above-mentioned 10 L internal stirring type reaction apparatus to perform a neutralization reaction. The neutralized product was washe...

Embodiment 3

[0115] First, 806g of powdery slurry (750g in anhydrous state) was added to a 10L internal stirring reaction device, 808g of sodium hydroxide aqueous solution (26wt%) was added to the reaction device, and then mixed at 45°C for 30 minutes Generate alkaline cellulose, wherein the weight ratio of sodium hydroxide and anhydrous cellulose is 0.280. Nitrogen purging was then carried out, 173 g of propylene oxide (0.230 parts by weight relative to cellulose) was added to the resultant, and then the mixture was reacted for 1.5 hours in a jacket at a temperature of 60° C., thereby obtaining 1787 g of hydroxypropyl fibers Crude reaction product of a prime with a molar substitution of hydroxypropoxy per anhydroglucose unit of 0.30. The etherification reaction rate was 46.4%.

[0116] Then, 629 g of acetic acid (50 wt %) was added to and mixed with the above-mentioned 10 L internal stirring type reaction apparatus, and a neutralization reaction was performed. The neutralized product wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com