Method for realizing modification of carbon nano-tube by using polymer crystallization

A technology of carbon nanotubes and polymers, which is applied in the direction of carbon nanotubes, nanotechnology for materials and surface science, nanocarbons, etc., to achieve the effects of weak force, simple process, and increased compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

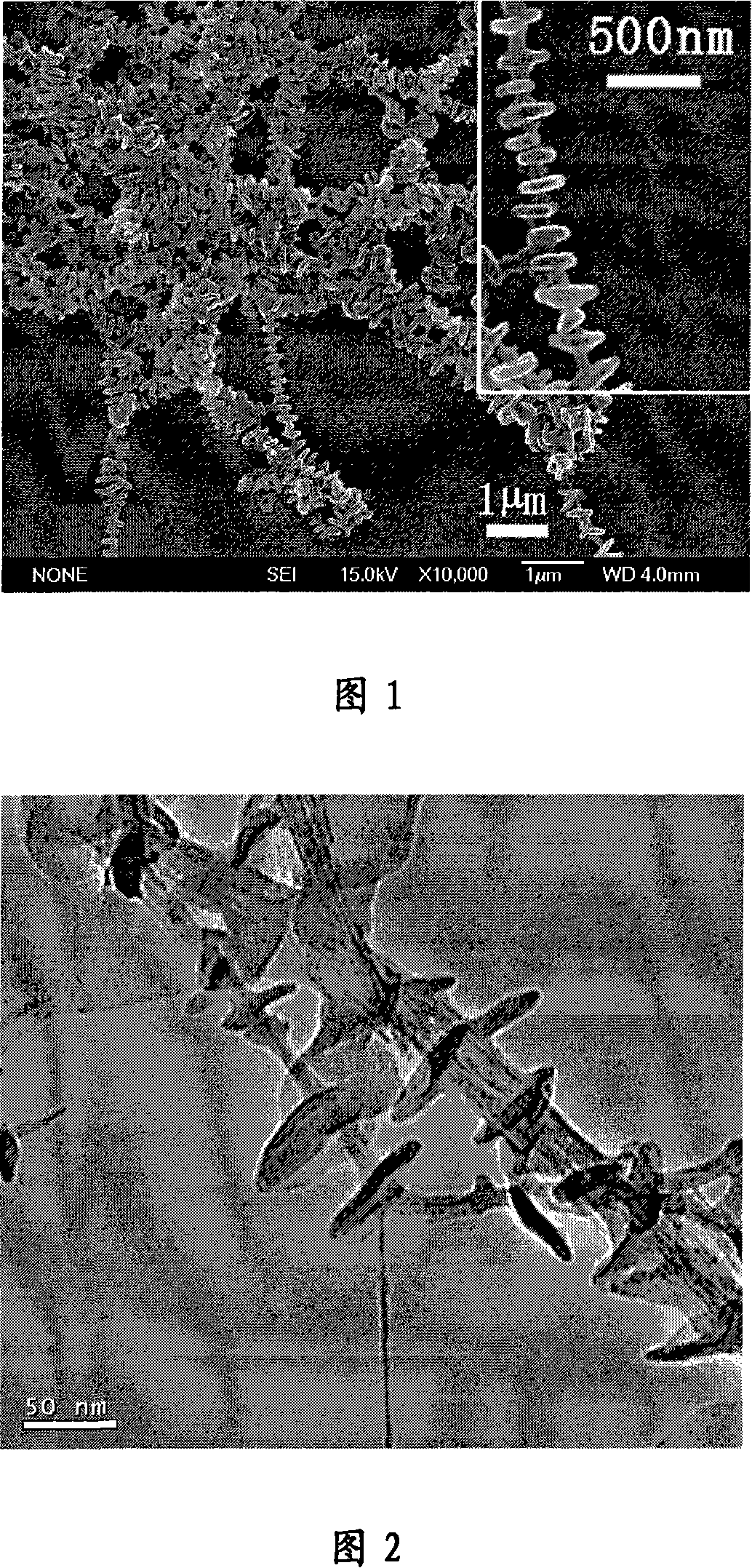

Image

Examples

Embodiment 1

[0024] Dissolve 1.0 mg of high-density polyethylene (HDPE) in 4 g of p-xylene at a constant temperature of 110 ° C, and at the same time, ultrasonically disperse 0.1 mg of single-walled carbon nanotubes in 1 g of p-xylene at 45 ° C to 50 ° C SWNTs, after the HDPE is completely dissolved and the SWNTs are completely dispersed, mix the p-xylene solution of HDPE and the SWNTs / p-xylene dispersion system at 110° C., and finally form the concentration of HDPE to 0.02wt%, and the concentration of SWNTs to be 0.002wt%. After the system is balanced, the p-xylene solution of HDPE / SWNTs is quickly transferred to the autoclave with a constant temperature of 110 °C; inject CO into the autoclave 2 to 9MPa, and maintain the high pressure for 3 hours, and finally slowly reduce the pressure to normal pressure, open the kettle and take out all the products, which are high-density polyethylene modified carbon nanotubes.

Embodiment 2

[0026] The amount of HDPE is 0.5mg, and the concentration of the finally formed HDPE is 0.01wt%. Others are the same as in Example 1.

Embodiment 3

[0028] The amount of HDPE was changed to 0.3 mg, and the concentration of the finally formed HDPE was 0.006 wt %, and the others were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com