Biomulsifier and its manufacturing method

A bioemulsifier and aerobic fermentation technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of high cost and difficult application, so as to improve speed and thoroughness, and promote contact Density and strength, effect of increasing degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

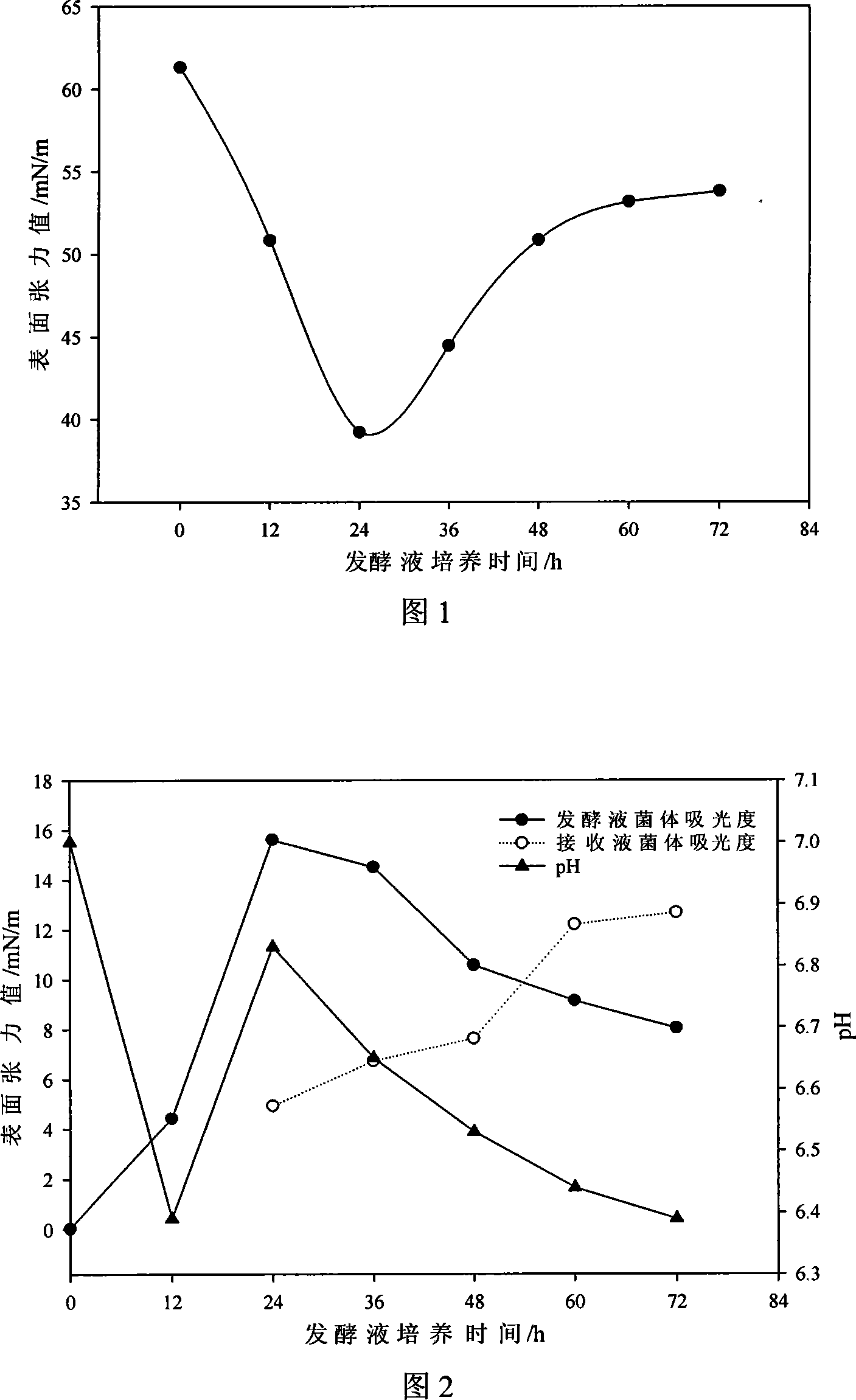

[0019] Embodiment 1: Preparation of biological emulsifier of the present invention

[0020] The bacterial classification used in the present invention is Bacillus subtilis (numbering CCTCC Bacillus subtilis AB93108), and this bacterial classification is purchased from China Typical Culture Collection Center, and is inoculated once on the slant medium every 1 to 2 months, and bacterial classification is in 4 Store under ℃ conditions. Take the refrigerated strains and activate them at 30°C for 24 hours, and then use an inoculation loop to pick a ring of strains from the slant culture medium in the aseptic operating table and inoculate them into the seed culture solution, which was pre-heated in a high-pressure steam cooker at 115 Sterilize at ℃ for 30min. The inoculated seed culture solution was placed in a constant temperature incubator for cultivation at 30° C. and 200 rpm. The composition of the seed culture solution is: NaCl 5.0g, peptone 5.0g, beef powder 3.0g, distilled ...

Embodiment 2

[0024] Embodiment 2: preparation bioemulsifier of the present invention

[0025] As in Example 1, take the strains refrigerated at 4°C and activate them at 37°C for 24 hours, then use an inoculation loop to pick a ring of strains from the slant culture medium in the aseptic operating table and inoculate them in the seed culture solution, and the seeds are cultivated The solution was sterilized in a high-pressure steam boiler at 115°C for 30 minutes in advance, and the inoculated seed culture solution was placed in a constant temperature incubator at 37°C and 250rpm. The composition of the seed culture solution is: 4.0g of NaCl, 4.0g of peptone, 2.5g of beef powder, 1000mL of distilled water, and adjust the pH to 7.2 with 1M NaOH.

[0026] The seed culture solution cultured for 24 hours was inoculated into the fermentation culture solution at an inoculation amount of 5% by volume. The composition of the fermentation broth is: glucose 45g, NH 4 NO 3 7.3g, K 2 HPO 4 ·3H 2 ...

Embodiment 3

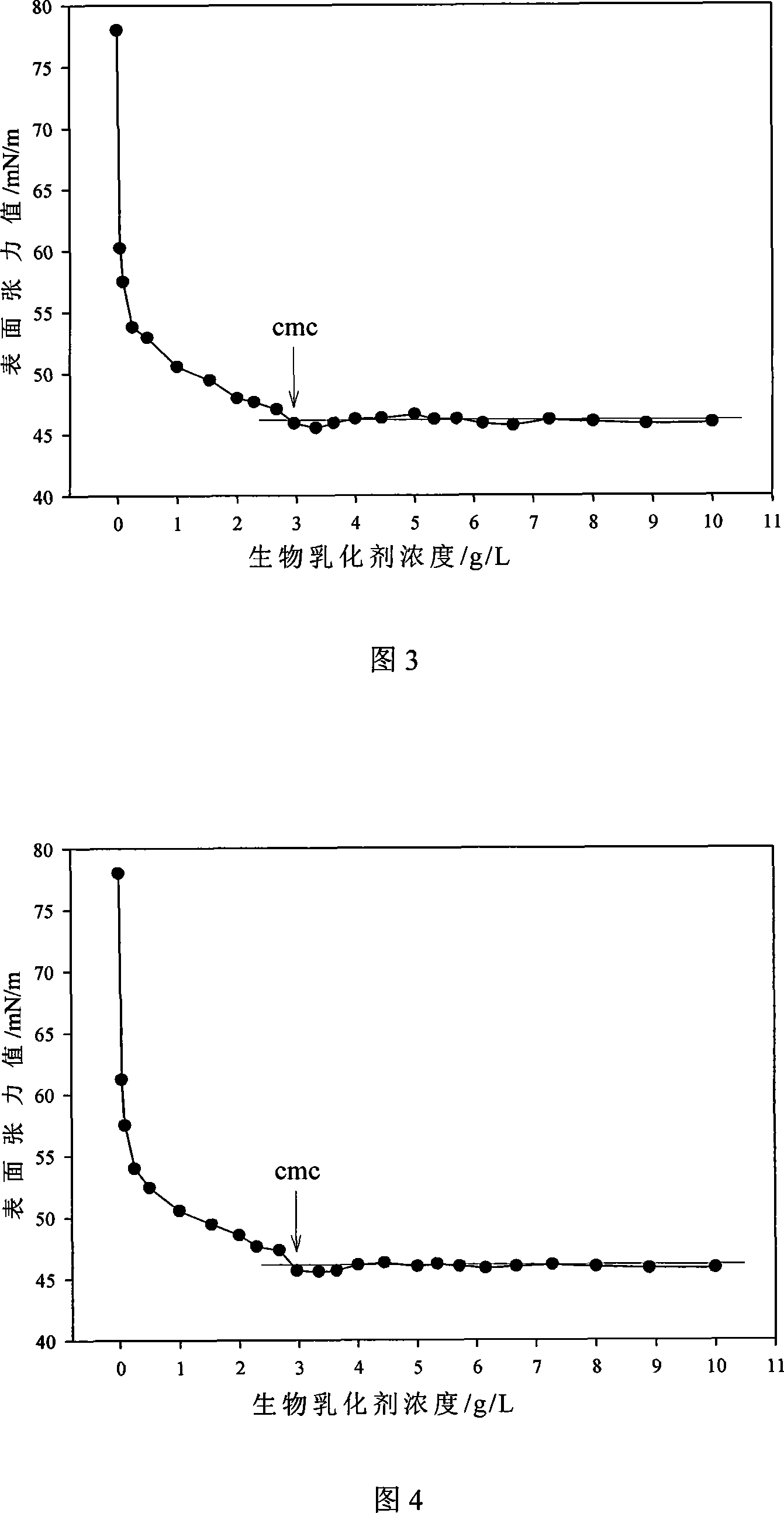

[0030] Composition and properties of the bioemulsifier prepared in Examples 1 and 2:

[0031] 1) Lipids (lipids) content

[0032] Weigh 0.2g bioemulsifier, dissolve and extract lipids with 6.0mL chloroform / methanol (V:V=2:1) mixed solution, then centrifuge at 7332×g for 10min, collect the supernatant, and the residue in the centrifuge tube Extraction was continued by the above method, repeated 3 times. The collected organic extract phase was evaporated in vacuo at 46°C and weighed. The lipid content in the bioemulsifier was measured to be zero.

[0033] 2) Protein content

[0034] The protein content in the bioemulsifier was determined by the Coomassie brilliant blue method, bovine serum albumin was used as the standard sample, and the light absorption wavelength was selected as 595nm. The mass percentage of protein in the biological emulsifier was determined to be 45.6±0.3% in the experiment.

[0035] 3) Sugar content

[0036] The sugar content in the bioemulsifier wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com