Polylactic acid and electron beam radiation modified method for derivative of the same

A technology of electron beam radiation and polylactic acid, which is applied in the field of modification of polylactic acid and its derivatives, to achieve the effects of expanding the application field, shortening the preparation cycle, and expanding the scope of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

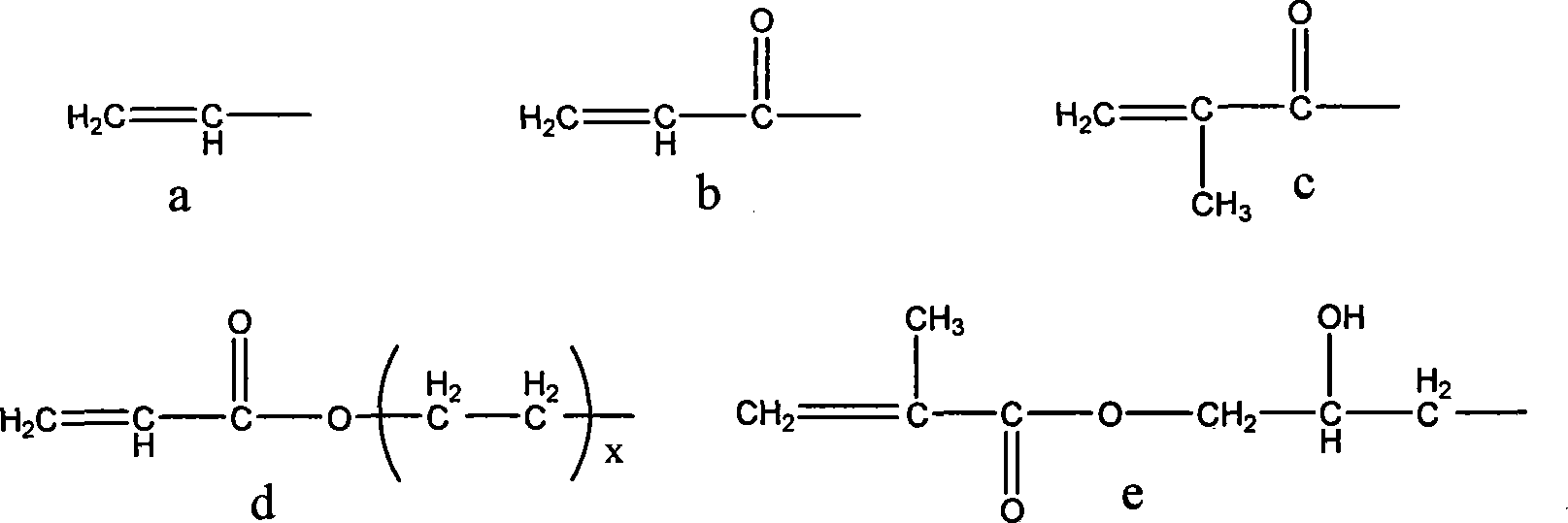

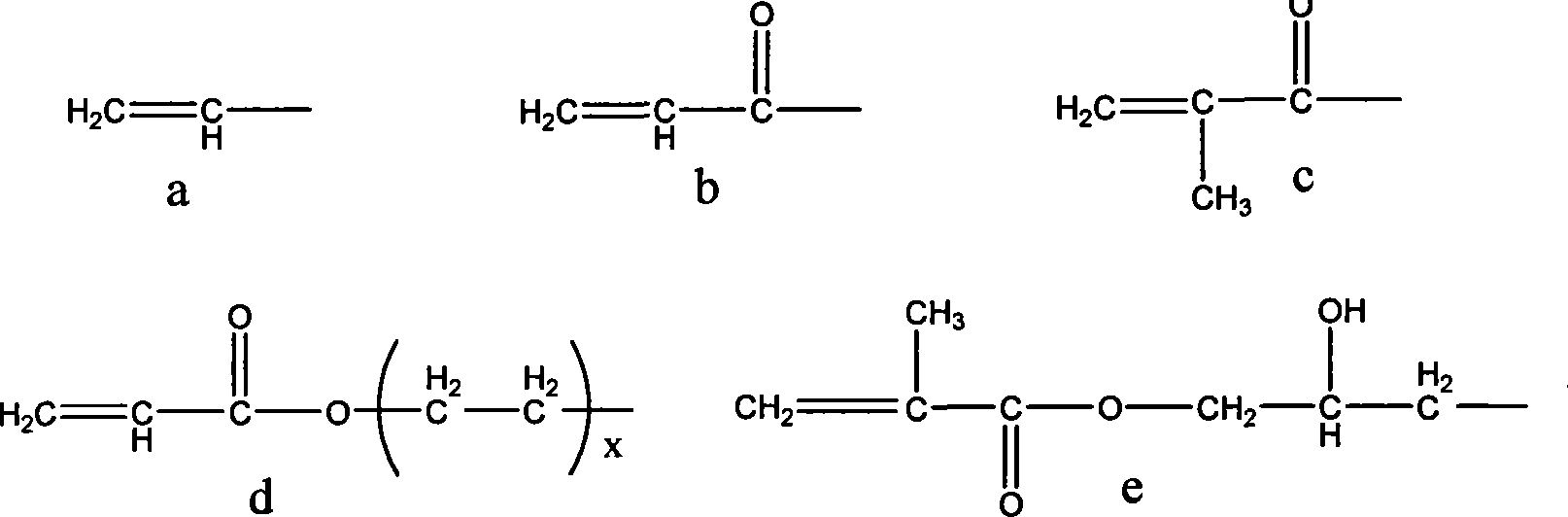

Image

Examples

Embodiment 1

[0060] Heat polylactic acid (polylactic acid 1) to 180°C for 3 minutes, then cool to room temperature, and cold press at room temperature to form a sheet or film; pass nitrogen to discharge the air in the irradiation room of the electron beam equipment, when the oxygen concentration in the irradiation room drops When it reaches 1mg / L, start the electron beam equipment, send the polylactic acid sheet or film into the irradiation chamber of the electron beam equipment, close the irradiation chamber; irradiate with electron beam at room temperature (25°C), and the radiation dose is 55kGy. The obtained modified polylactic acid has a softening temperature of 70° C., a tensile strength of 5.0 MPa, an elongation at break of 20.9 percent, and a biodegradation rate of 96 percent within 140 hours.

Embodiment 2

[0062] Heat acrylic acid-terminated polylactic acid (polylactic acid 2, R is an acrylic acid group (b)) to 180 ° C for 3 minutes, then cool to room temperature, and cold press at room temperature to form a sheet or film; blow nitrogen to discharge the electron beam equipment Irradiate the air in the room. When the oxygen concentration in the irradiation room drops to 20mg / L, start the electron beam equipment, send the acrylic acid-terminated polylactic acid sheet or film into the irradiation room of the electron beam equipment, and close the irradiation room; at room temperature (25 ℃) with electron beam radiation, the radiation dose is 105kGy. The softening temperature of the obtained modified acrylic-terminated polylactic acid is 191° C., the tensile strength is 39.6 MPa, the elongation at break is 13.1%, and the biodegradation rate is 68% within 140 hours.

Embodiment 3

[0064] Heat the block polyethylene glycol-polylactic acid copolymer (polylactic acid 3) to 180°C for 3 minutes, then cool to room temperature, and cold press at room temperature to form a sheet or film; blow nitrogen to exhaust the electron beam equipment irradiation room Air, when the oxygen concentration in the irradiation room drops to 100mg / L, start the electron beam equipment, send the block polyethylene glycol-polylactic acid copolymer sheet or film into the irradiation room of the electron beam equipment, and close the irradiation room; Electron beams were used to irradiate at room temperature (23° C.), and the radiation dose was 10 kGy. The obtained modified block polyethylene glycol-polylactic acid copolymer has a softening temperature of 73° C., a tensile strength of 8.9 MPa, an elongation at break of 367.8%, and a biodegradation rate of 91% within 140 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com