Laser plastic micro-welding method

A welding method and plastic technology, applied in diffraction gratings, microlithography exposure equipment, photolithography exposure devices, etc., can solve the problem of unsatisfactory welding results, inability to weld micro-fine parts, and warping deformation of plastic parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

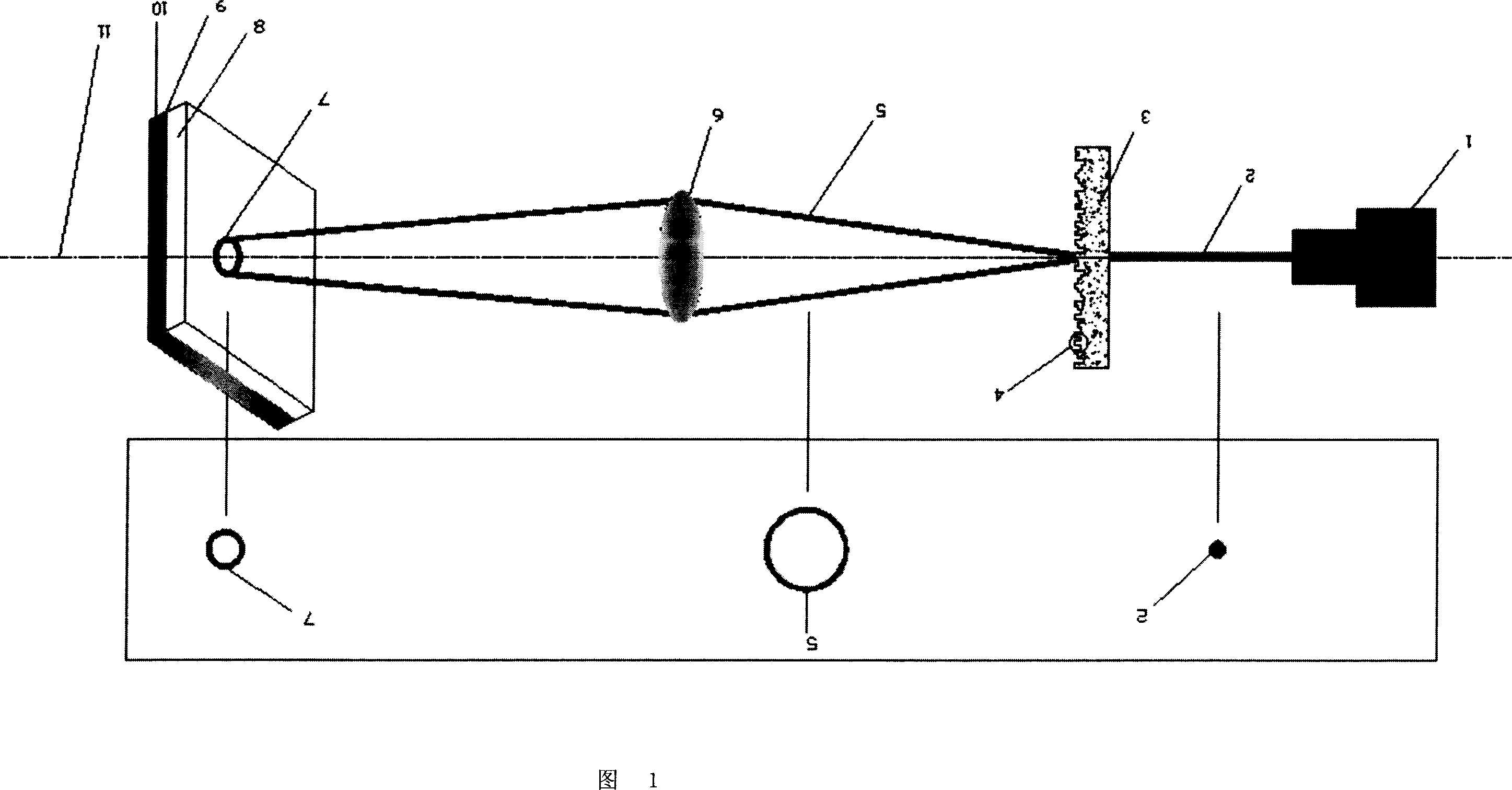

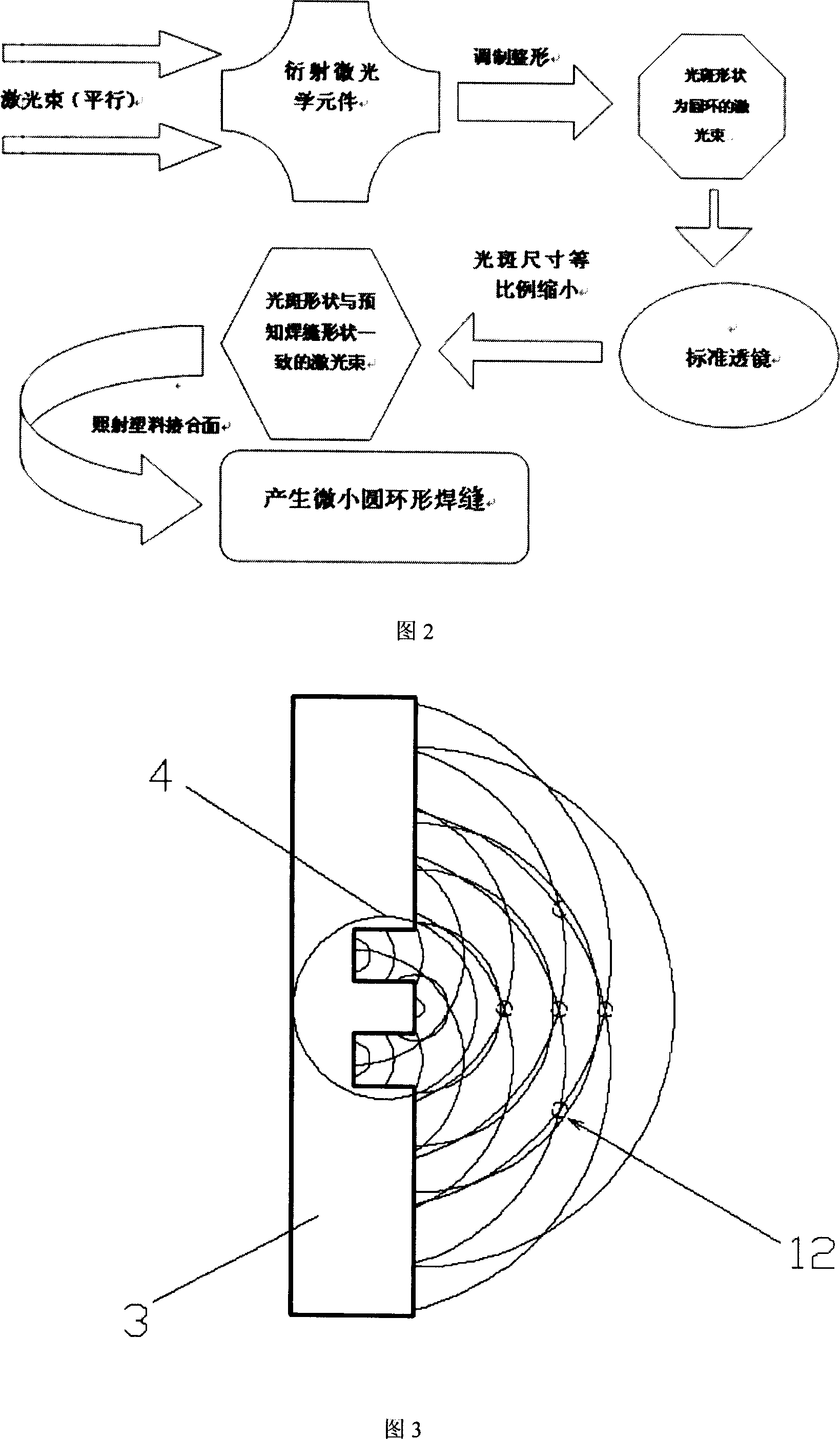

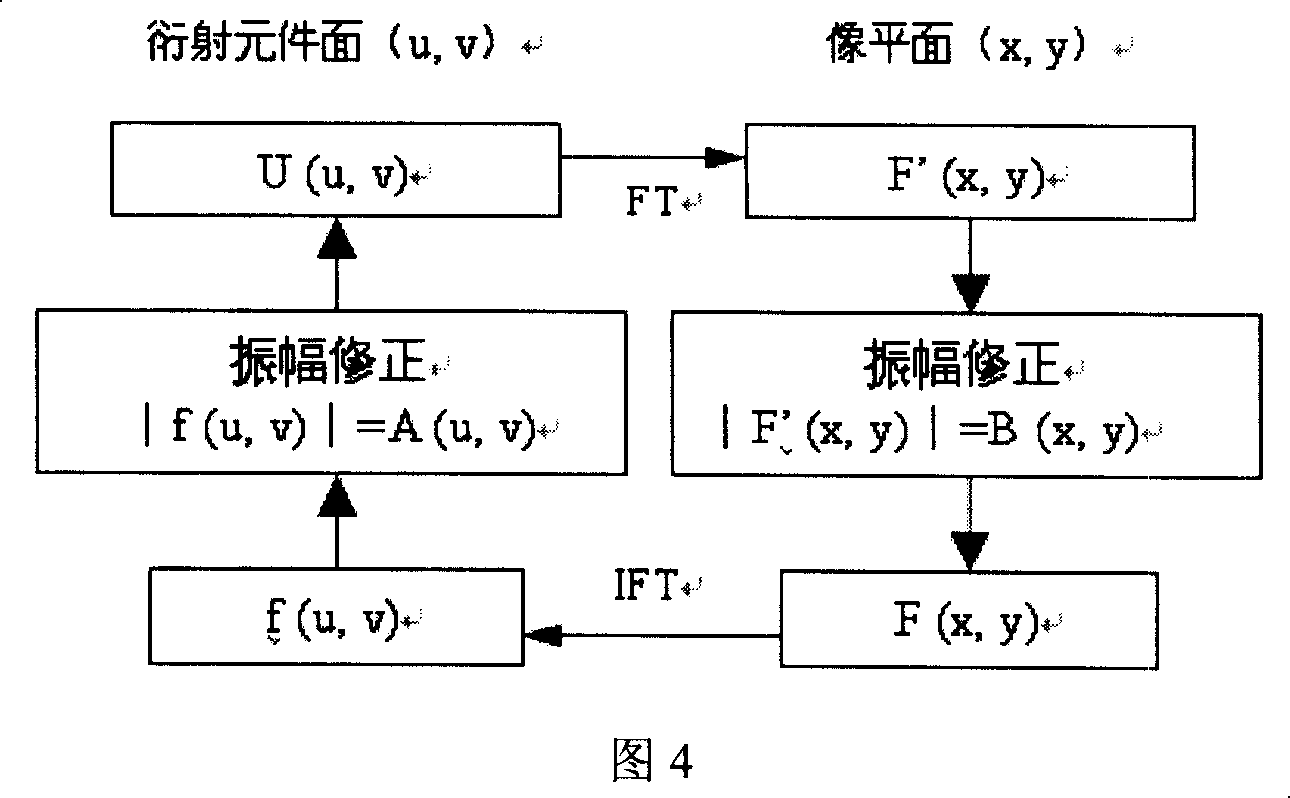

[0014] Now take the welding seam as an example to implement laser plastic micro-welding.

[0015] The welding plastics selected are: translucent polycarbonate (PC): length: 25mm, width: 25mm, thickness: 0.3mm; light-absorbing polycarbonate (PC): length: 25mm, width: 25mm, thickness: 3mm.

[0016] According to the two-slit diffraction mode, the diffraction equation can be obtained: y = mλD d , where y is Diffraction pattern size, m is the diffraction order, D is the distance between the slit and the screen, and λ is the wavelength of the laser beam. It can be seen from the equation that y is constant (the weld shape is known), m is a fixed value, and d is the distance between the two slits, that is, the characteristic size of the diffraction grating. Generally, the characteristic size of the diffraction grating is between 5 μm and 25 μm. According to the diffraction equation, it can be seen that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com