Polyimide multilayered adhesive film and process for producing the same

A polyimide layer, polyimide technology, used in chemical instruments and methods, film/sheet adhesives, adhesives, etc. problem, to achieve the effect of continuous productivity and uniform film thickness and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

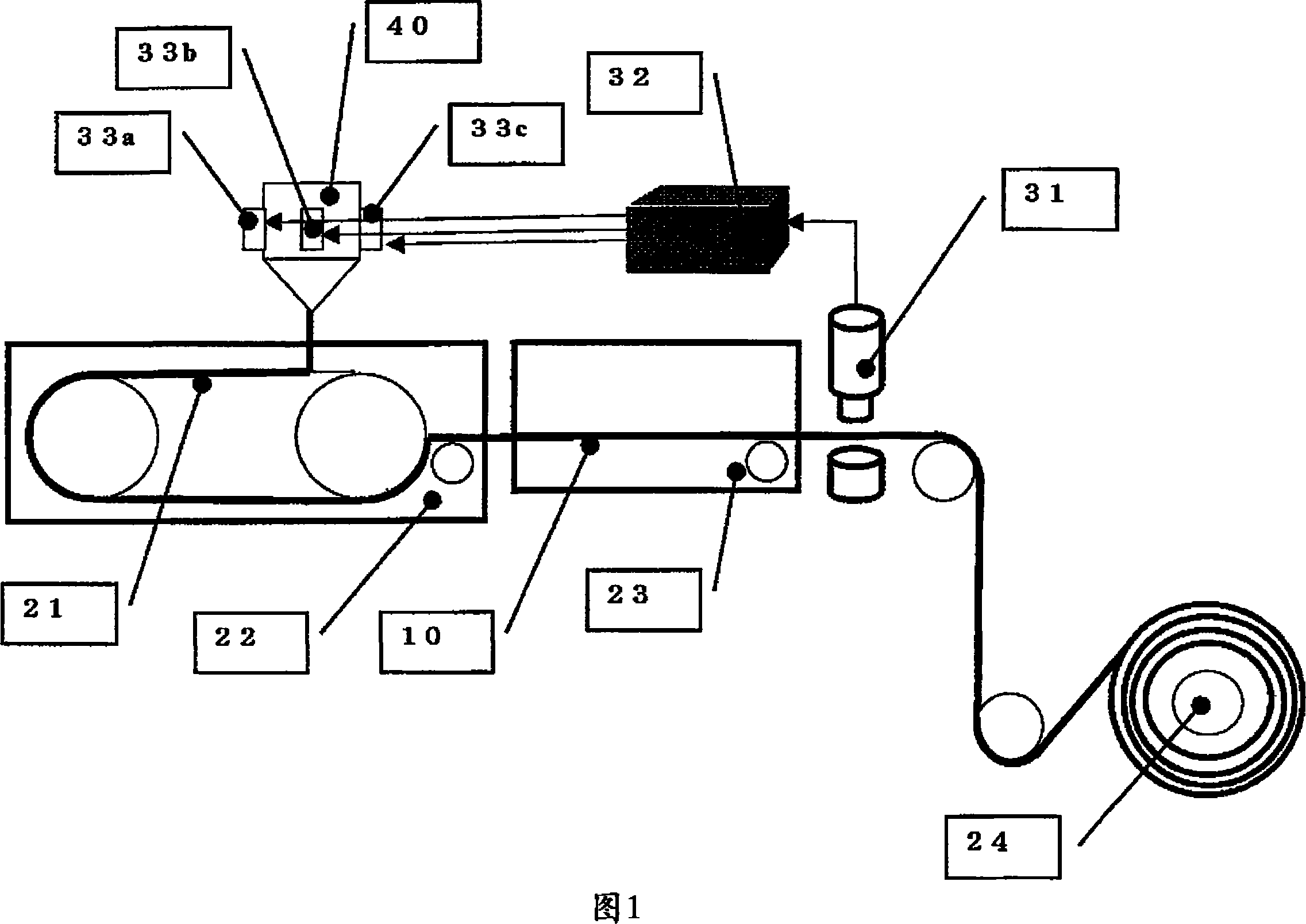

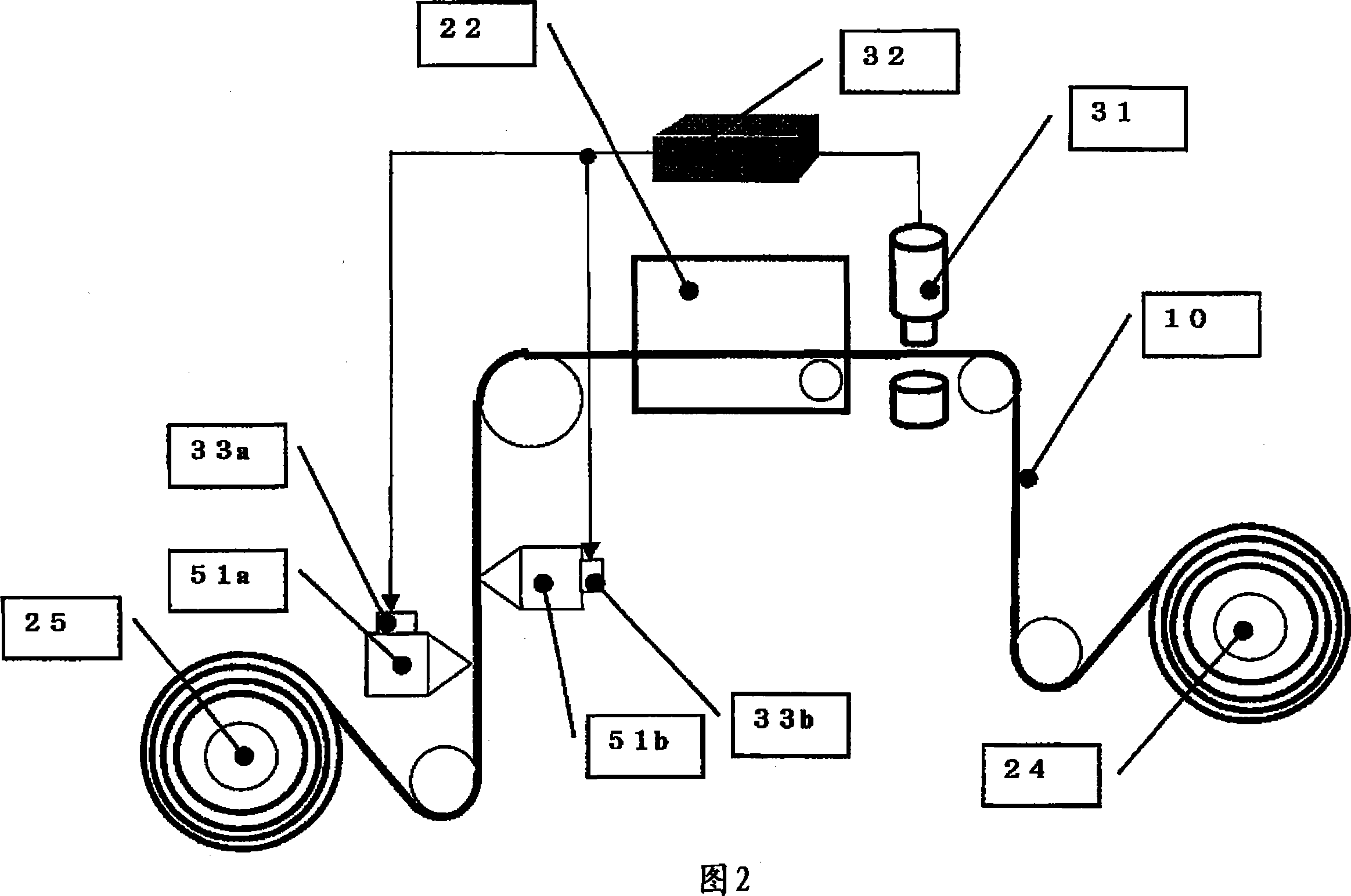

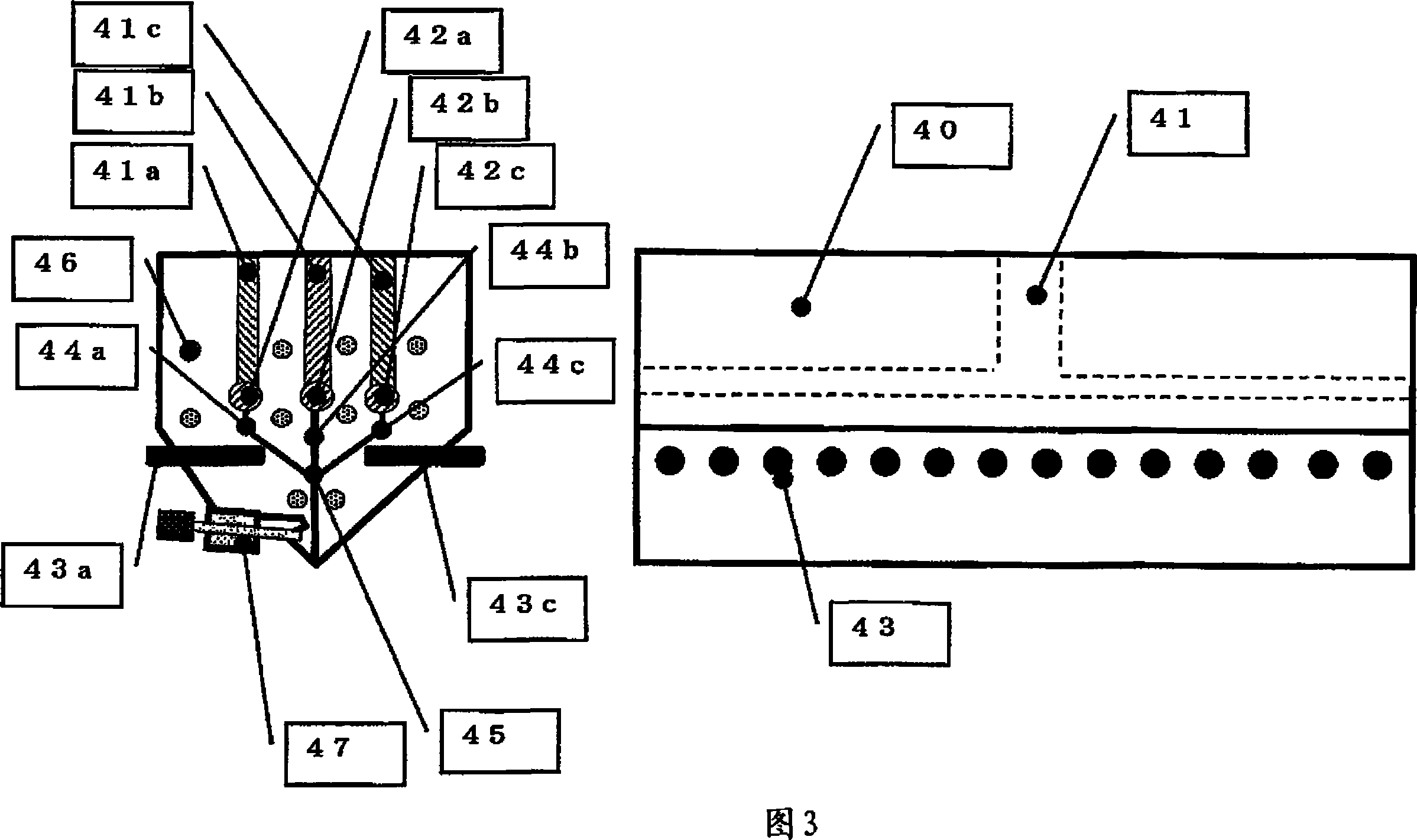

Method used

Image

Examples

Embodiment

[0162] Hereinafter, an example of the method of the present invention will be given and described in detail, but the present invention is not limited to this example.

Synthetic example 1

[0163] (Synthesis Example 1: Synthesis of polyamic acid as a precursor of highly heat-resistant polyimide compounds)

[0164] Add 76.2kg of DMF cooled to 10°C, 3.7kg of p-phenylenediamine (PDA), and slowly add 9.8kg of 3,3',4,4'-biphenyltetracarboxylic acid di Anhydride (BPDA), stirred for 30 minutes. Separately, a solution obtained by dissolving 300 g of BPDA in 2 kg of DMF was prepared, and this was slowly added to the above-mentioned reaction solution while paying attention to the viscosity, followed by stirring. When the viscosity reached 3500 poise, the addition and stirring were stopped to obtain a solution of polyamic acid which is a precursor of a highly heat-resistant polyimide compound.

[0165] In this synthesis example, when the thickness of each layer was measured by an infrared absorption method, there was no functional group exhibiting a characteristic infrared absorption wavelength.

Synthetic example 2

[0166] (Synthesis Example 2: Synthesis of polyamic acid as a precursor of highly heat-resistant polyimide compounds)

[0167] 6.9kg of 4,4'-oxydianiline (hereinafter also referred to as ODA), 6.2kg of p-phenylenediamine (hereinafter also referred to as p-PDA), 9.4kg of 2,2-bis[4- (4-Aminophenoxy) phenyl] propane (hereinafter also referred to as BAPP) was dissolved in 239 kg of N, N-dimethylformamide (hereinafter also referred to as DMF) cooled to 10 ° C, and 10.4 kg of Pyromellitic dianhydride (hereinafter also referred to as PMDA) was stirred for 1 hour and dissolved. 20.3 kg of benzophenone tetracarboxylic dianhydride (hereinafter also referred to as BTDA) was added there, and stirred for 1 hour to dissolve it.

[0168] The DMF solution of PMDA prepared separately (PMDA:DMF=0.9kg:7.0kg) was slowly added to the above reaction solution, and the addition was stopped when the viscosity reached about 3000 poise. Stirring was performed for 1 hour to obtain a solution of polyamic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com