Method and vertical kiln for producing magnetic ferrous powder

A technology of iron powder and magnetism, applied in the field of magnetic iron powder, can solve the problems of low product qualification rate, limited combustion space, inability to realize continuous industrialized production, etc., and achieves increased heat exchange efficiency, accurate and convenient temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

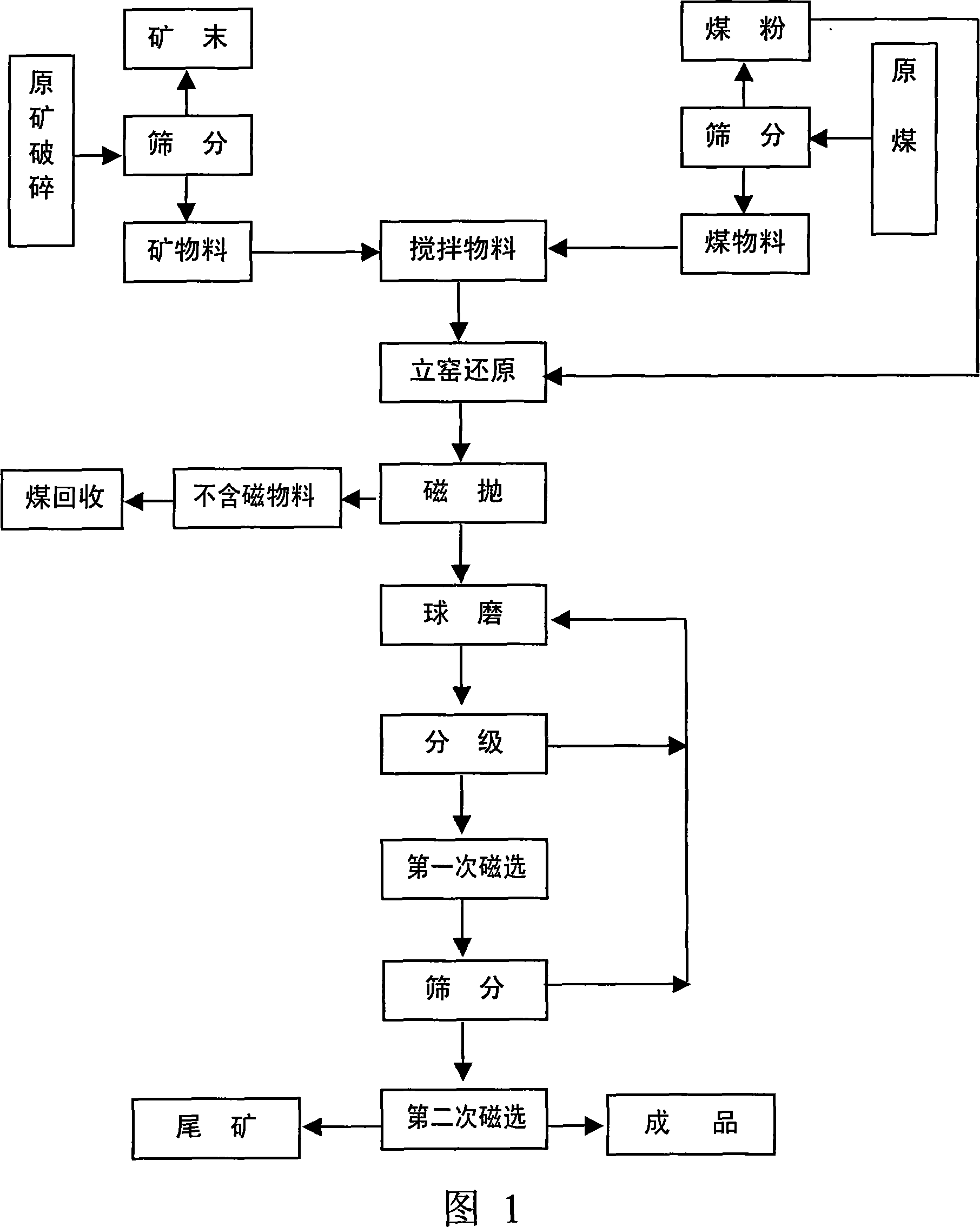

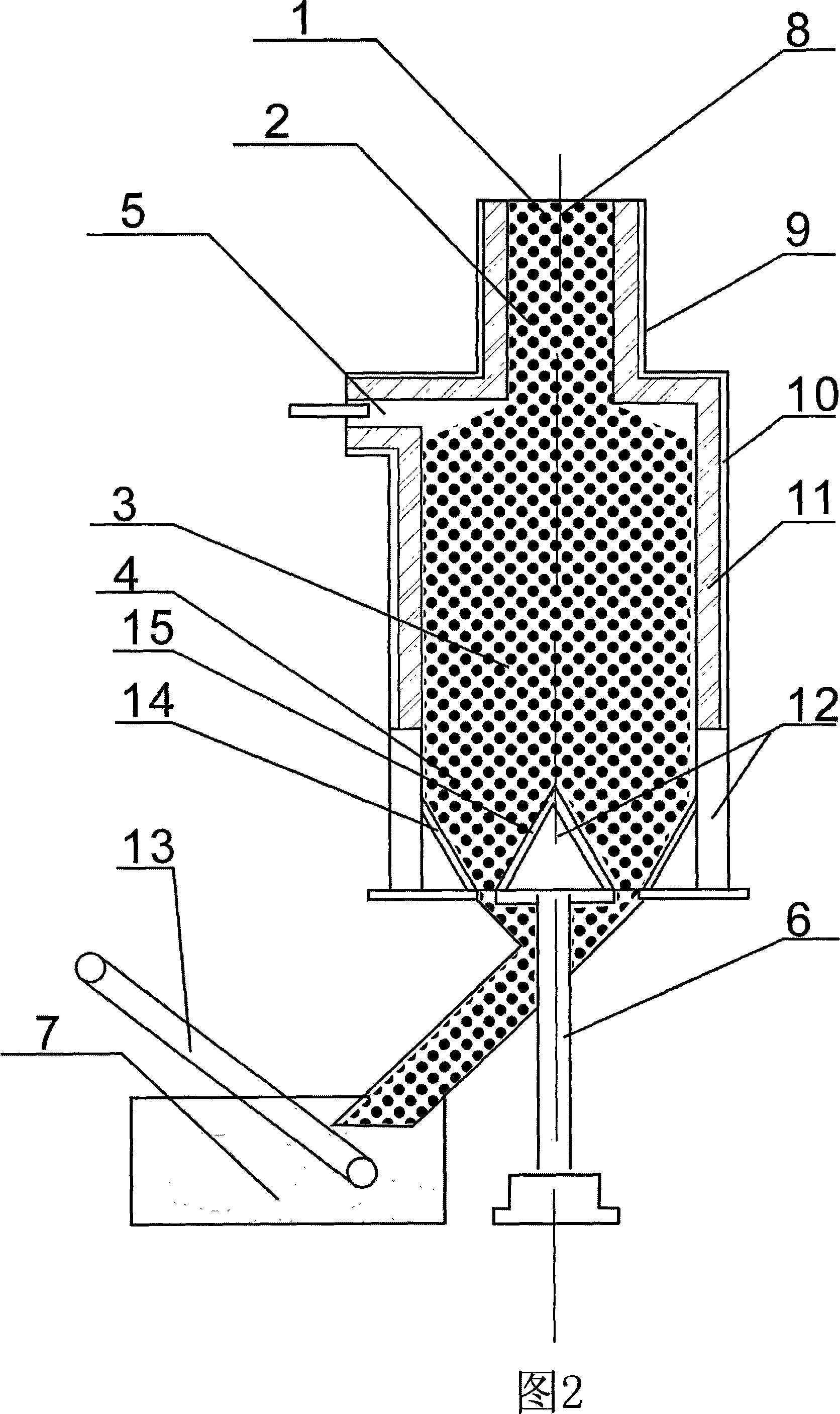

[0033] The invention discloses a method for producing magnetic iron fine powder, which uses hematite as raw material and adopts a vertical kiln reduction method, and coal is used as both a reducing agent and a fuel, and the vertical kiln reduction is continuous production. The production steps are to crush the hematite and coal first, and then sieve to ensure that the particle size is between 2mm and 13mm. Mix the coal as the reducing agent with hematite and other raw and auxiliary materials evenly. At the entrance, the coal as fuel is injected from the side of the shaft kiln together with the air, and the reaction product is obtained by continuous reduction reaction in the reduction section of the shaft kiln. After cooling the reaction product in the cooling section, it is sealed and cooled out of the kiln, and the reaction product is magnetically Throwing, remove coal and other non-magnetic substances, ball mill the magnetic substances in the ball mill, conduct the first magn...

Embodiment 2

[0036]The invention discloses a method for producing magnetic iron fine powder, which uses hematite as raw material and adopts a vertical kiln reduction method, and coal is used as both a reducing agent and a fuel, and the vertical kiln reduction is continuous production. The production steps are to first crush the raw iron ore and coal, and then sieve to ensure that the particle size is between 2mm and 13mm. Mix the coal as the reducing agent with various raw and auxiliary materials such as hematite evenly, and enter from the upper part of the vertical kiln. The coal used as fuel is sprayed from the side of the shaft kiln together with the air, and the reaction product is obtained by continuous reduction reaction in the reduction section of the shaft kiln. After cooling in the cooling section, the reaction product is sealed and cooled out of the kiln, and the reaction product is magnetically thrown. , remove non-magnetic substances such as coal, ball mill the magnetic substanc...

Embodiment 3

[0039] The invention discloses a method for producing magnetic iron fine powder, which uses hematite as raw material and adopts a vertical kiln reduction method, and coal is used as both a reducing agent and a fuel, and the vertical kiln reduction is continuous production. The production steps are to first crush the raw iron ore and coal, and then sieve to ensure that the particle size is between 2mm and 13mm. Mix the coal as the reducing agent with various raw and auxiliary materials such as hematite evenly, and enter from the upper part of the vertical kiln. The coal used as fuel is sprayed from the side of the shaft kiln together with the air, and the reaction product is obtained by continuous reduction reaction in the reduction section of the shaft kiln. After cooling in the cooling section, the reaction product is sealed and cooled out of the kiln, and the reaction product is magnetically thrown. , remove non-magnetic substances such as coal, ball mill the magnetic substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com