Method for producing solid-phase microextraction capillaries

A capillary and extraction technology, applied in the field of analytical chemistry, achieves the effect of simple method, good reproducibility and large extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Functional monomer: 5 μL of glycidyl methacrylate, crosslinking agent: 65 μL of ethylene glycol dimethacrylate, porogen: 10 μL of toluene and 180 μL of dodecanol, initiator: 0.8 mg of azobisisobutyronitrile Mix and stir evenly at room temperature, pour into a vinyl-modified quartz capillary, seal, and initiate polymerization at 60°C for 20 hours. After the polymerization is completed, fully wash the capillary with methanol to remove unreacted monomers, crosslinking agents and Pore agent. The obtained monolithic column capillary was washed with 0.1 mol / L sulfuric acid for 3 hours to obtain a hydroxylated glycidyl methacrylate-ethylene glycol dimethacrylate polymer monolithic column capillary.

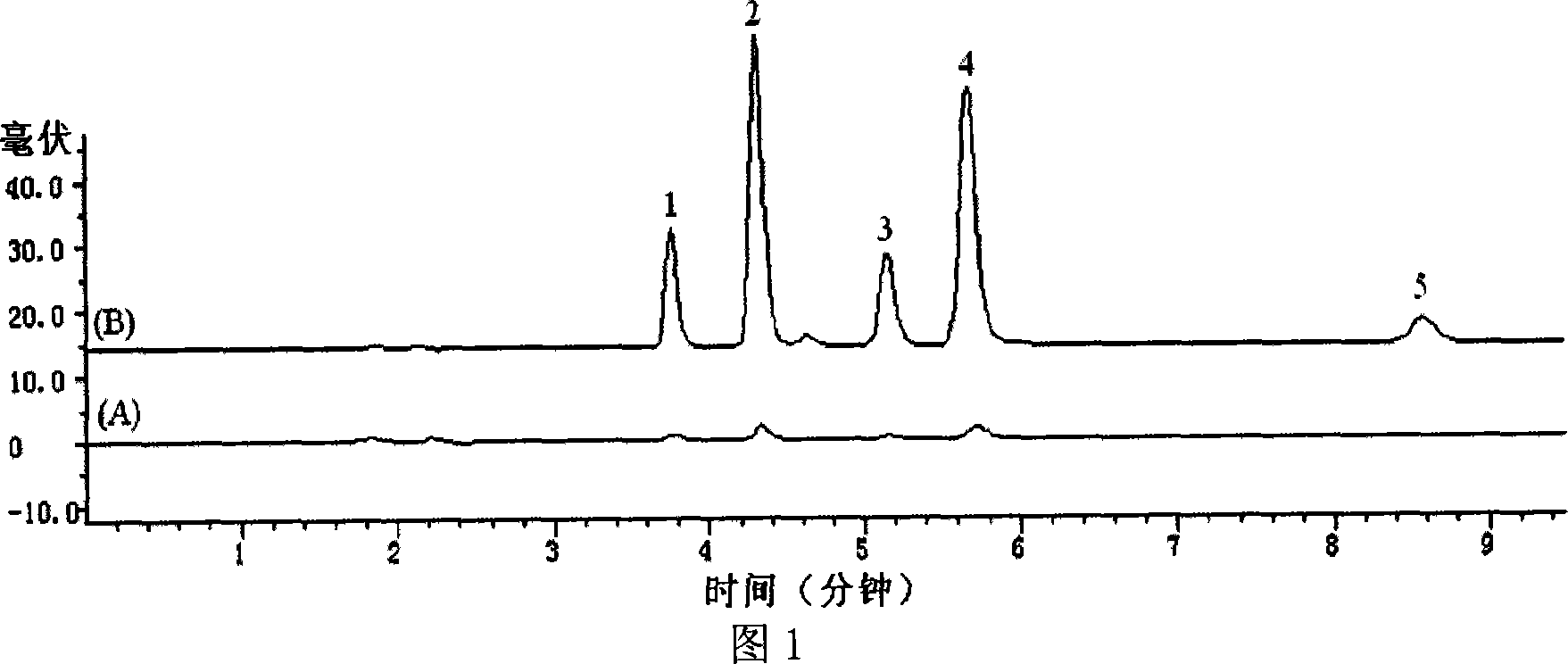

[0020] With the prepared hydroxylated glycidyl methacrylate-ethylene glycol dimethacrylate polymer monolithic column capillary as the extraction medium, the in-tube solid phase microextraction and high performance liquid chromatography provided by the patent number ZL 03 2 54844...

Embodiment 2

[0025] Functional monomer: 10 μL of glycidyl methacrylate, crosslinking agent: 70 μL of ethylene glycol dimethacrylate, porogen: 15 μL of toluene and 210 μL of dodecanol, initiator: 1.2 mg of azobisisobutyronitrile Mix and stir evenly at room temperature, sonicate for 10 minutes to remove air bubbles, pour into a vinyl-modified quartz capillary, seal, and initiate polymerization at 65°C for 16 hours. After the polymerization reaction is complete, the capillary is thoroughly washed with acetonitrile to remove unreacted monomer, crosslinker and porogen. The resulting monolithic column capillary was washed with 0.5 mol / L sulfuric acid for 3 hours to obtain a hydroxylated glycidyl methacrylate-ethylene glycol dimethacrylate polymer monolithic column capillary.

[0026] With the prepared hydroxylated glycidyl methacrylate-ethylene glycol dimethacrylate polymer monolithic column capillary as the extraction medium, the in-tube solid phase microextraction and high performance liquid c...

Embodiment 3

[0031]Functional monomer: 5 μL of glycidyl methacrylate, crosslinking agent: 70 μL of ethylene glycol dimethacrylate, porogen: 20 μL of toluene and 180 μL of dodecanol, initiator: 1.0 mg of azobisisobutyronitrile Mix and stir evenly at room temperature, sonicate for 5 minutes to remove air bubbles, pour into a vinyl-modified quartz capillary, seal, and initiate polymerization at 55°C for 24 hours. After the polymerization reaction is completed, the capillary is thoroughly washed with acetonitrile, methanol, or tetrahydrofuran to remove unreacted monomers, crosslinkers, and porogens. Then rinse the resulting glycidyl methacrylate-ethylene glycol dimethacrylate polymer monolithic column capillary with diethylamine for 2 hours, seal it, and react at 70°C for 5 hours to obtain diethylamine derivatized methacrylic acid shrink Glyceride-ethylene glycol dimethacrylate polymer monolithic column capillary.

[0032] Using the monolithic column capillary of glycidyl methacrylate-ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com