Controlled fertilizer of polymer capsule, production method, and dedicated capsule material

A technology for coating materials and controlled-release fertilizers, applied in fertilizer forms, fertilizer mixtures, applications, etc., can solve the problems of solvent toxicity, messy preparation materials of coated controlled-release fertilizers, etc., and achieve no irritating odor, safe and non-toxic processing technology. , The effect of solving the problem of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the screening of the material of producing coated fertilizer and solvent

[0032]The relatively cheap polyethylene is used as the main coating material. First, the film-forming performance and controlled-release performance are regulated by selecting low-density polyethylene with different average molecular weight and molecular secondary structure. Research the controlled-release performance of the coating material system combined with low-density polyethylene and linear low-density polyethylene, and develop a new coating material formula. Second, according to the principle of "like dissolves like" of polymers, with reference to the solubility parameters of polyolefin (polyethylene), select solvents with similar solubility values and low toxicity (organic chemical volumes compiled with reference to hazardous chemicals standards) for experiments. Screen solvents with excellent solubility and low toxicity, and find solvents that can dissolve polyethylene w...

Embodiment 2

[0046] Example 2, Controlled Release Performance Experiment of Coated Fertilizer Prepared by Coating System Obtained by Dissolving Polyethylene in Decalin, n-Octane and Cyclohexane

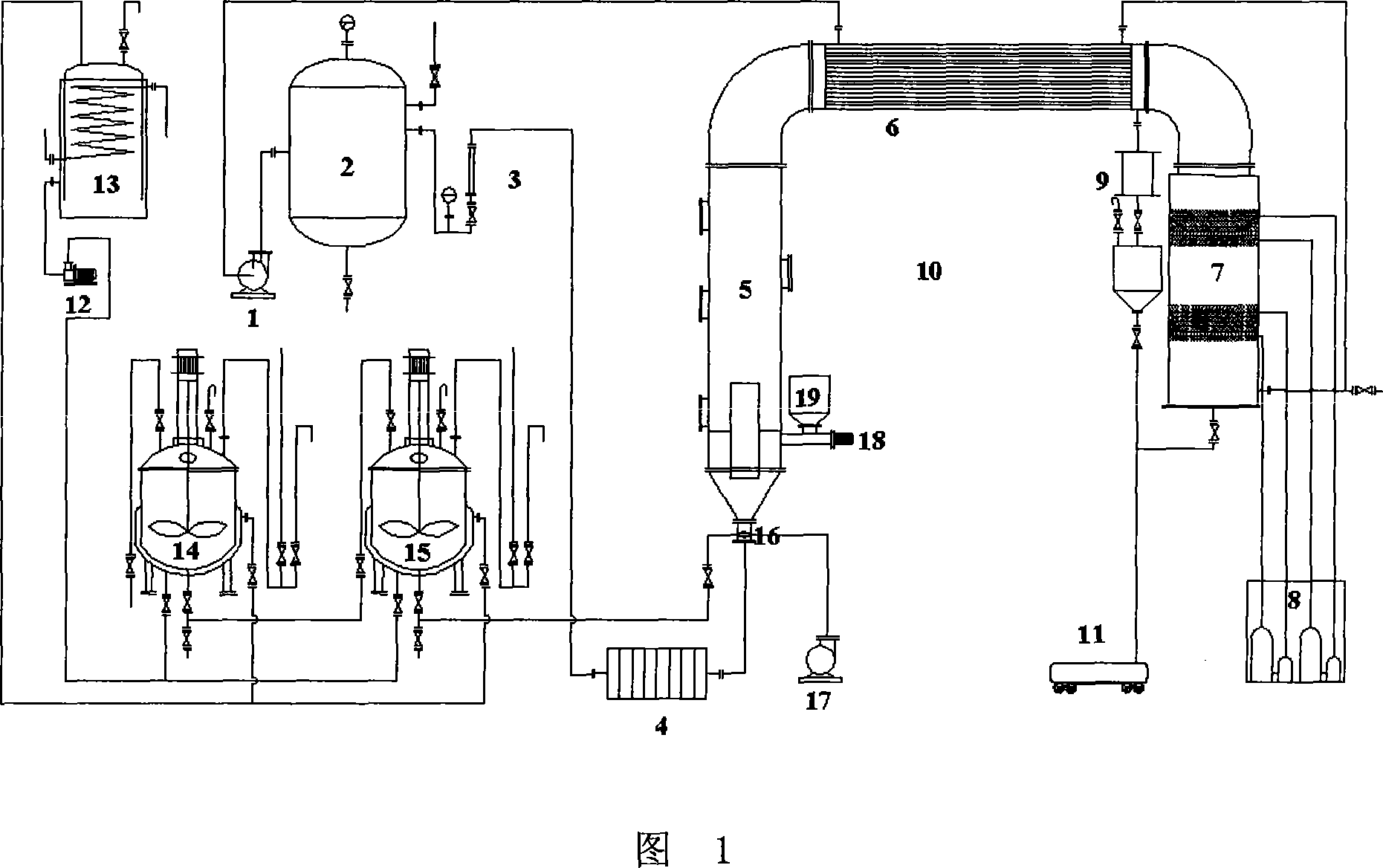

[0047] The processing device and process flow chart of coated fertilizer are shown in Figure 1: Among them, 1 in Figure 1 is the Roots blower (model WL20~5 / 0.20), 2 is the buffer tank, and 3 is the flow meter (model LZB-100) 4 is an electric heater, 5 is a fluidized bed, 6 is a shell and tube condenser, 7 and 8 are air coolers; 9 is a sight cup; 10 is a solvent receiver, 11 is a solvent bucket, and 12 is an oil pump (the model is BRY ), 13 oil storage tanks, 14 and 15 are reactors, 16 is a two-fluid nozzle, 17 is an air compressor (model: V-0.14 / 10C), 18 is an automatic feeder, and 19 is a feed hopper.

[0048] Utilize the processing device as shown in Figure 1, the technological process step that adopts is:

[0049] Step 1: Add coating materials such as organic solvents and polymers into the rea...

Embodiment 3

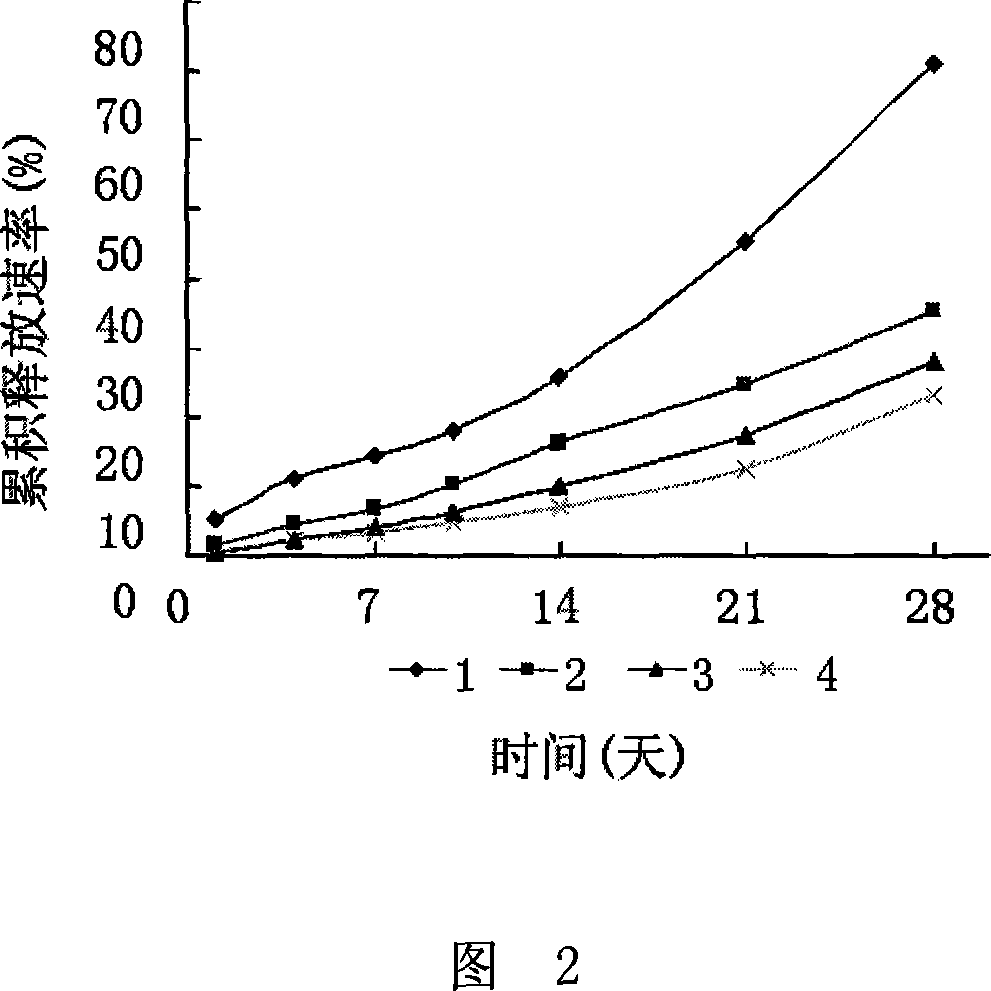

[0069] Embodiment 3, the impact of different linear polyethylene ratios on the nutrient release performance of coated fertilizers

[0070] According to the preparation method of the coated fertilizer described in Example 2, two different linear types of branched low-density polyethylene (LDPE, brand 1F7B) and linear low-density polyethylene (LLDPE, brand: DFDA-7042) are used. The polyethylene material (set 4 ratios, as shown in table 3), use cyclohexane as solvent, obtain corresponding 4 processing schemes (shown in table 3 1,2,3 and 4), each handles three repeat. See Table 3 for the specific ratio configuration and usage of other materials. The coated controlled-release fertilizer was prepared with different ratios of polyethylene.

[0071] Four kinds of coated controlled-release fertilizers prepared above are respectively tested for release performance according to the evaluation method of coated fertilizer performance described in Example 2. The release performance of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com