Method and device of carrying out blaze cutting weld by using pentane liquid as fuel

A technology of cutting and welding and pentane, which is applied in the field of flame cutting and welding with pentane liquid as fuel and its devices, which can solve the problems affecting the quality of cutting or welding, unstable quality of purchased gasoline, and complex gasoline components, etc. , to achieve the effect of simple structure, low cost and good ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

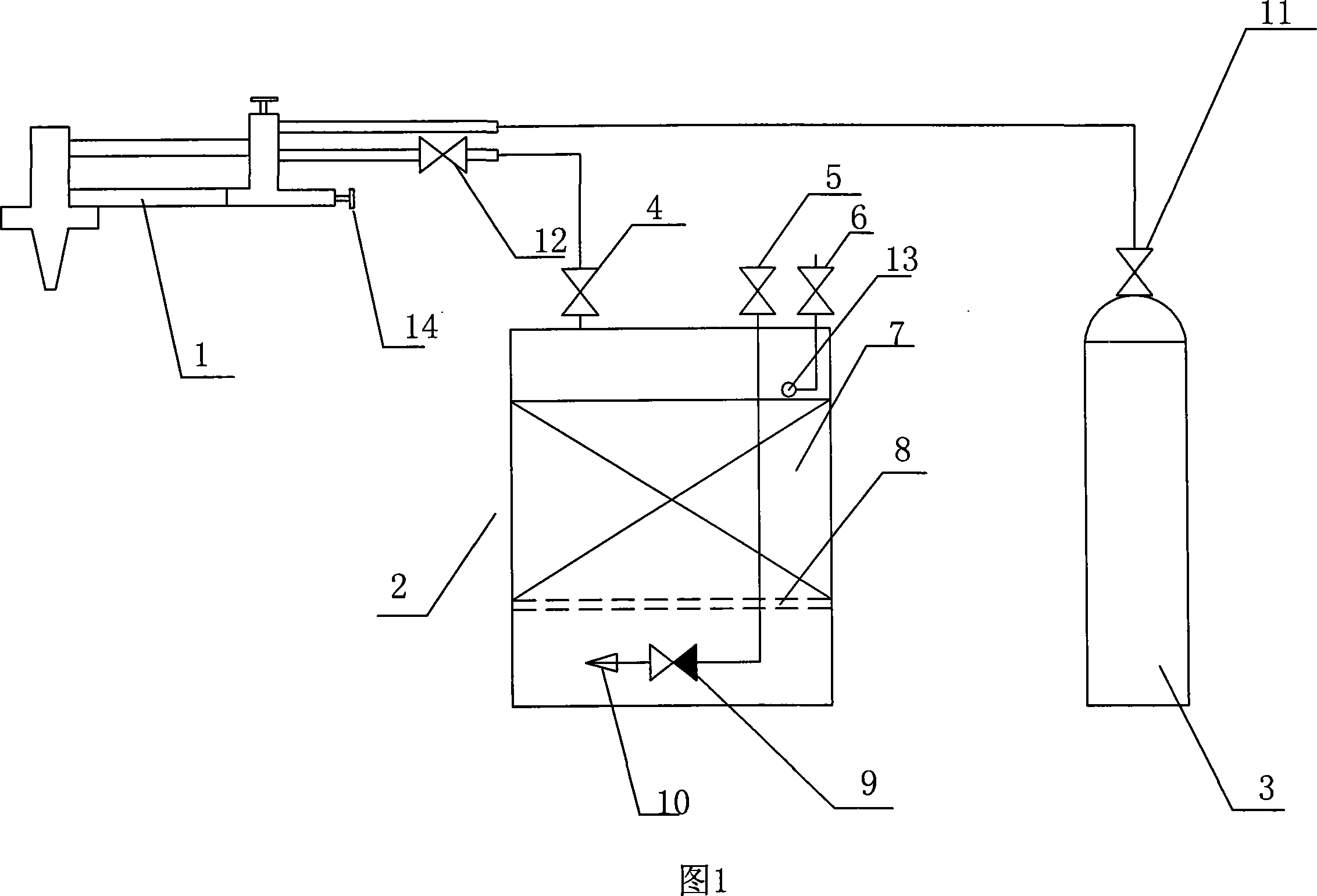

[0010] The method and device of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] See shown in accompanying drawing 1, present embodiment comprises jet-suction cutting welding torch 1, evaporator 2, oxygen bottle 3, and the oxygen joint of jet-suction cutting welding torch 1 is equipped with pressure regulation on flexible pipe and oxygen bottle 3. The valve 11 is connected, and the gas connector of the injection-suction cutting torch 1 is connected with the evaporator 2 through a hose, wherein the gas connector has a gas valve 12, and the evaporator 2 also has a gas valve 4, and the evaporator is equipped with a Explosion-proof wire 7, sieve plate 8, sieve plate 8 is located at the bottom of explosion-proof wire 7, check valve 9 and muffler distributor 10 are installed under the sieve plate 8, one end of check valve 9 is connected with muffler distributor 10, The other end is connected with the breathing valve 5 outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com