Preparation metod of modified ultroviolet light solidified wooden articles paint by in-situ method

A technology for curing coatings and ultraviolet light, which is applied in the direction of polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy aggregation of nano-materials, influence on ultraviolet light absorption, complex process conditions, etc., and achieve simple process Ease of operation, avoiding the difficulty of dispersion, and the effect of scientific technical route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

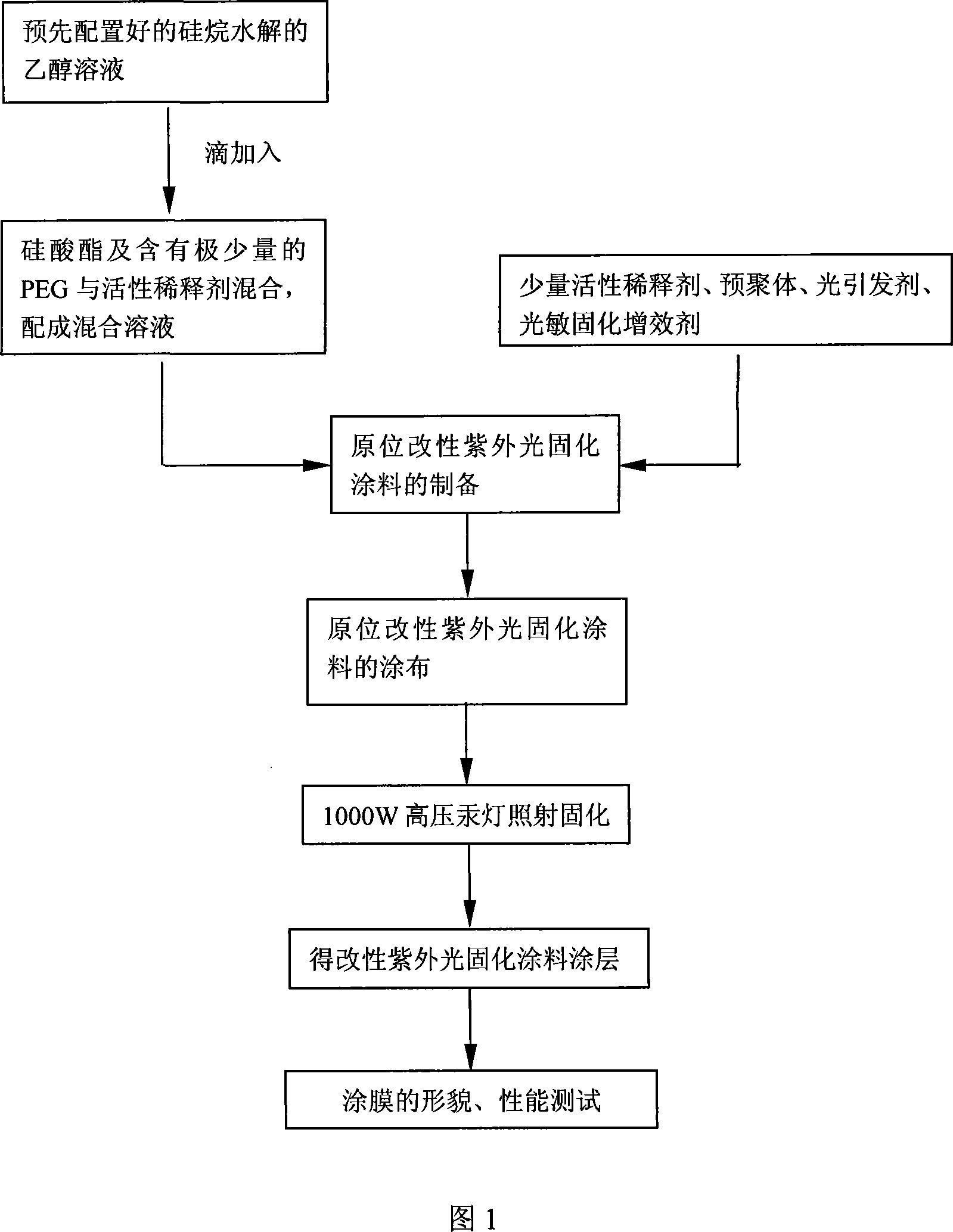

Method used

Image

Examples

Embodiment 16

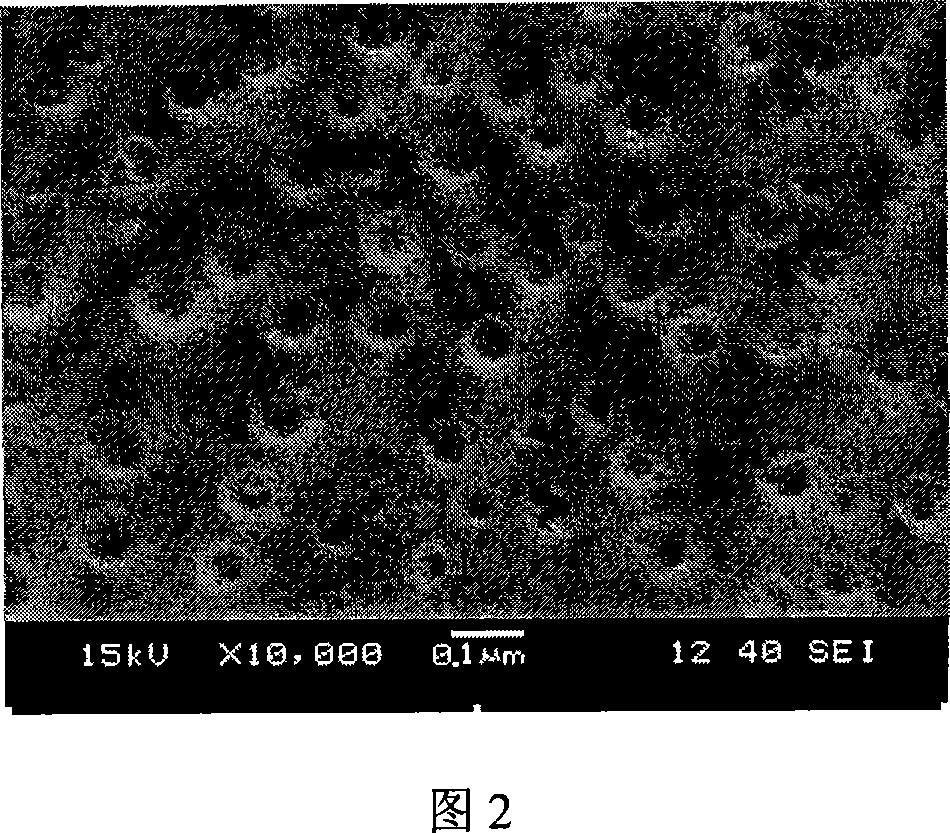

[0021] The coating described in embodiment 16, after adopting modes such as roller coating, spray coating, flow coating etc. to be applied on wood surface, gained coating film performance is better, and accompanying drawing 2 is the SEM figure of coating film, can find out from the figure: nanoparticle The distribution of UV coating is relatively uniform, and the particle size is also relatively uniform, generally distributed in the range of 60-80nm. In the figure, nano-SiO 2 There are obvious organic layer intervals between the sol particles, indicating that the in-situ modified UV coating has effectively solved the problem of nanoparticle agglomeration.

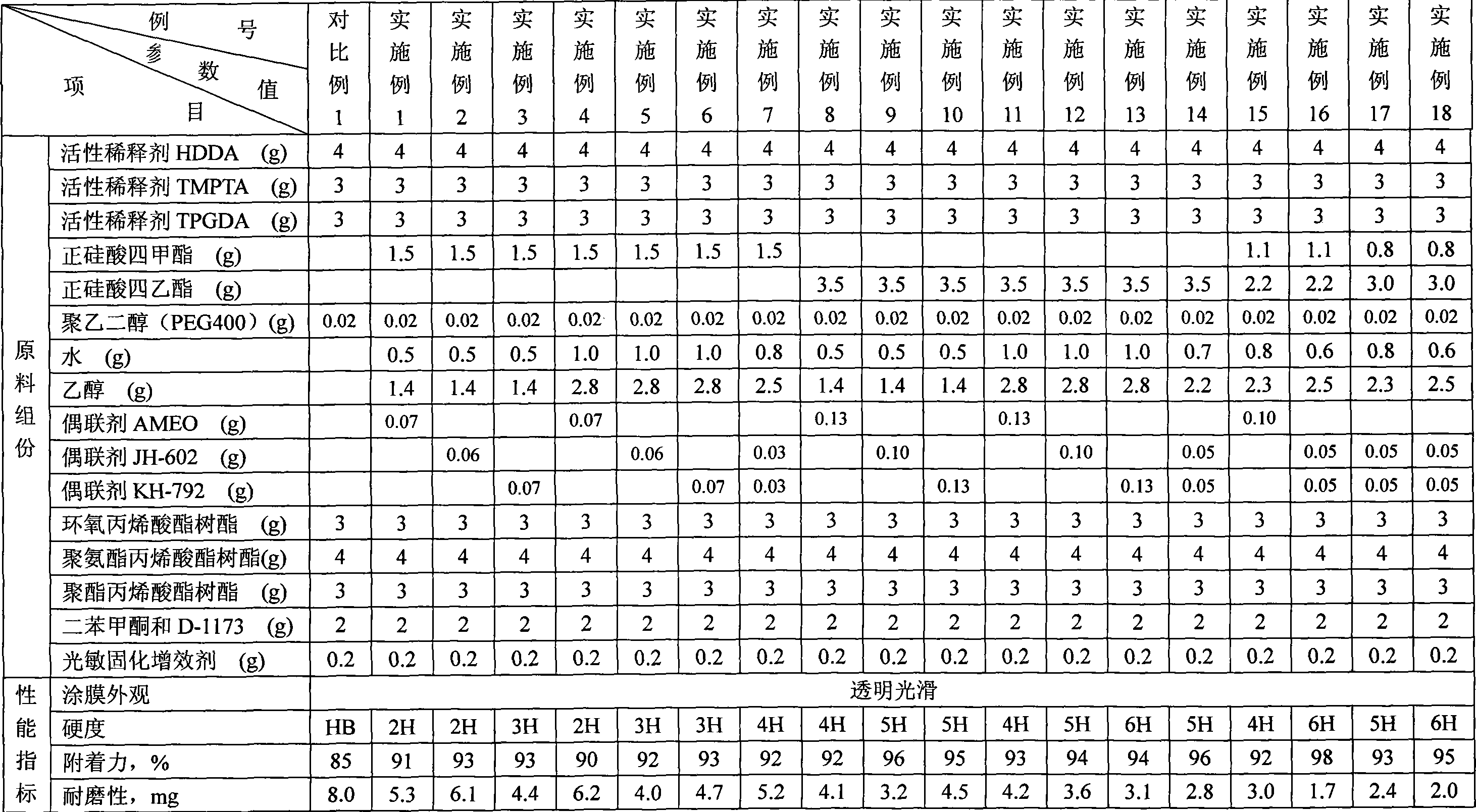

[0022] The different embodiments of table 1 and each component content of comparative example, relevant performance parameter

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com