Device and method for high-speed rapid growth of diamond single-crystal

A diamond single crystal, non-diamond technology, applied in the field of diamond single crystal materials and its preparation, to achieve the effects of good heat conduction, easy control and modulation, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

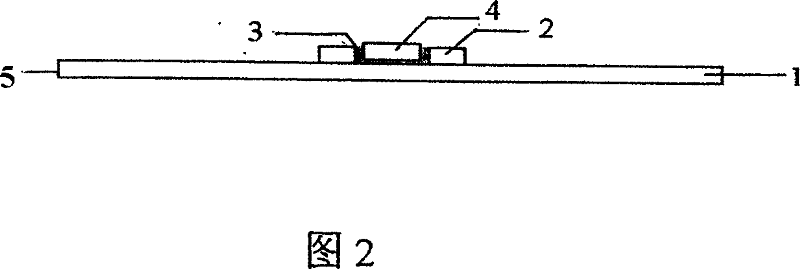

[0034] The device for high-speed growth of diamond single crystal of the present invention - the structure of the sample holder is illustrated with reference to the accompanying drawings. In Fig. 1 and Fig. 2, 1 is a polycrystalline diamond film, 2 is an annular frame, and the polycrystalline diamond film 1 and the annular frame 2 constitute a sample holder 5. That is, the sample holder 5 is equipped with a closed annular frame 2 on the polycrystalline diamond film 1. 3 is a diamond powder (particle size is micron or / and nanoscale), and 4 is a seed crystal.

[0035] When in use, the diamond seed crystal 4 can be placed in the hole in the annular frame 2 to directly grow the diamond single crystal. Diamond micropowder 3 can also be placed in the hole in the annular frame 2 of sample support 5, and seed crystal 4 is placed in the hole of annular frame 2, and makes the below of seed crystal 4 and the gap place between seed crystal 4 and annular frame 2 Filled with diamond microp...

Embodiment 2

[0038]The experiment used Seki's ASTex 5250 5kw (2.45GHz) microwave plasma chemical vapor deposition equipment, using high temperature and high pressure type Ib single crystal (100) diamond as the seed crystal, and homoepitaxially grown single crystal diamond on it at a high speed. The upper and lower (100) sides of the diamond seed crystal are mechanically polished, then ultrasonically cleaned in acetone, and finally placed in a specially designed polycrystalline diamond sample holder (see Figure 1), and the sample is placed in the deposition chamber. First pump down the pressure in the deposition chamber to below 0.1Pa. The gases used in the experiment were high-purity methane (4N), hydrogen (5N) and nitrogen (5N). The experiment is divided into two stages of etching and growth. In the etching stage, only hydrogen gas and nitrogen gas were fed, the flow rates were 500 sccm and 1.8 sccm respectively, and the growth surface of the diamond substrate was etched for 3 hours unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com