Hydraulic spile bridge and dyke construction

A technology of hydraulic boards and board bridges, applied in bridge construction, dams, embankments, etc., can solve the problems of difficult construction, poor resistance to wind and wave impact damage of the protective layer on the water-facing surface, and long construction period, so as to enhance safety and stability Performance, shortening the construction period of the project, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

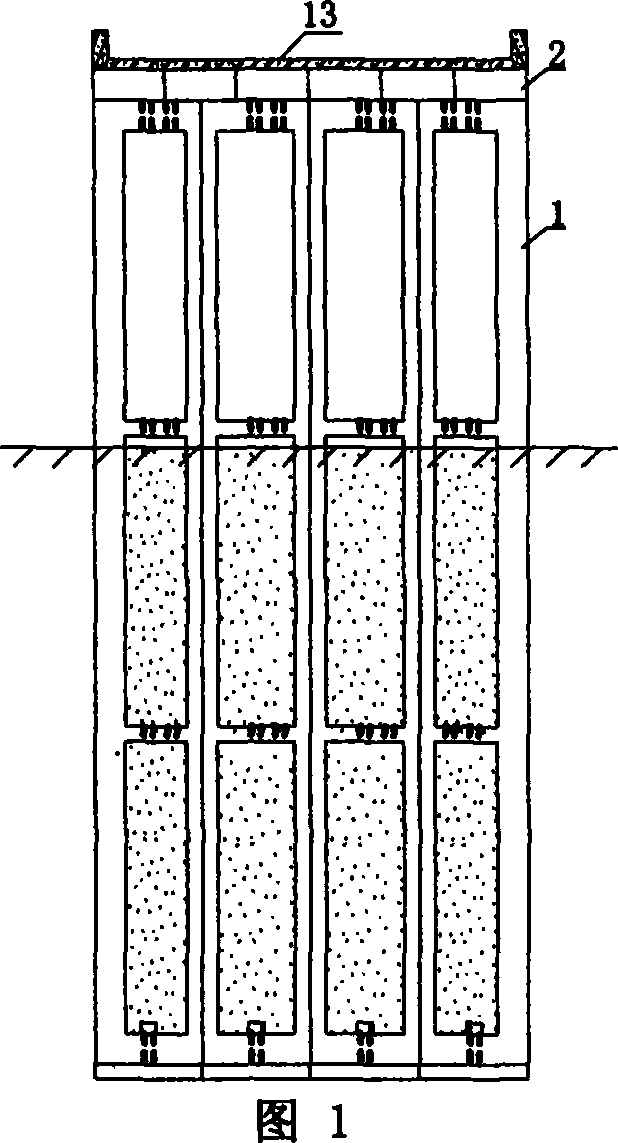

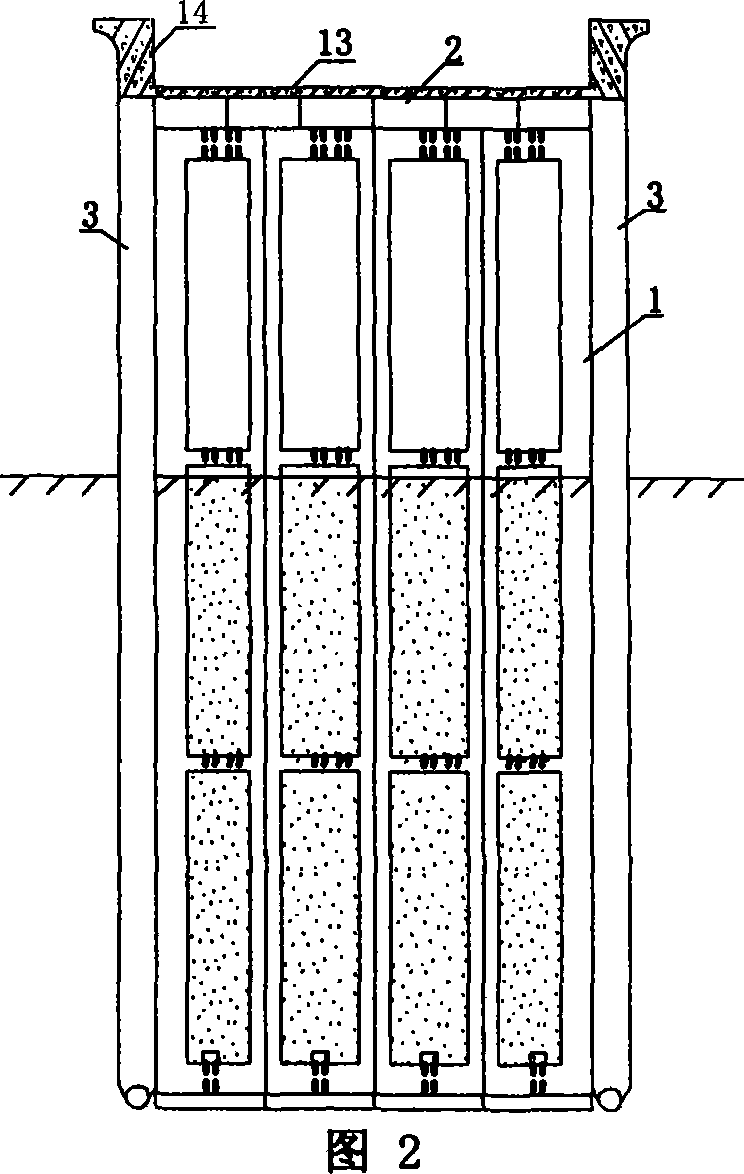

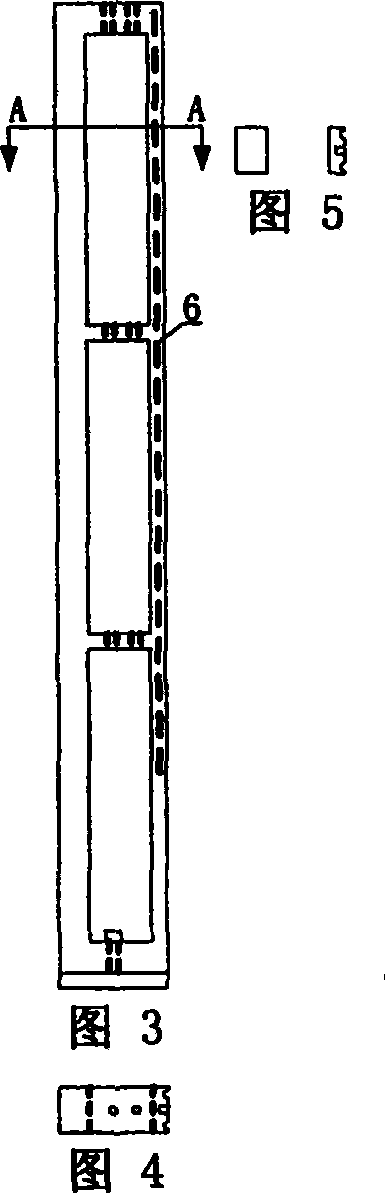

[0043] Referring to Figures 1 to 30, a hydraulic plug-in bridge includes a hydraulic plug-in bridge inserted into the formation and equipped with a slideway 6, a slide plate 7, a water distribution pipe 9, a water pipe 8, a Gaza conduit 10 and a water barrier. Pile slab 1, bridge deck 2 and cast-in-place concrete layer 13, bridge pile slab 1 is a combined overall concrete pier structure composed of a full-frame starting slab, middle slab and end slab connected to each other, and the bridge deck is directly laid on the top 2 and the cast-in-place concrete layer 13, between the frames and between the frame and the stratum is filled with sand or cement mortar consolidation 15.

[0044] One side of the middle plate is provided with a slideway 6, the other side is provided with a slide plate 7, and the starting plate and the end plate are only provided with a slideway or a slide plate in the inner side. The cross-sectional area of the outer leg of the start plate or the end plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com