Adhesive film and method for manufacturing semiconductor device using same

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, film/sheet-like adhesives, etc., can solve problems such as peeling problems, and achieve excellent shear strength characteristics and excellent fracture characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0146] Hereinafter, the present invention will be described in further detail through examples, but the present invention is not limited to these examples.

Synthetic example

[0149] (I) Thermosetting adhesive components

[0150] (I-1) Epoxy compound (manufactured by Mitsui Chemicals, Inc., VG3101)

[0151] (I-2) Imidazole-based curing agent (Shikoku Chemical Industry Co., Ltd., 2MAOK-PW)

[0152] (II) Silica-based filler (manufactured by Ryusen Co., Ltd., 1-FX)

[0153] (III) Synthesis example of polyimide resin component

Synthetic example 1

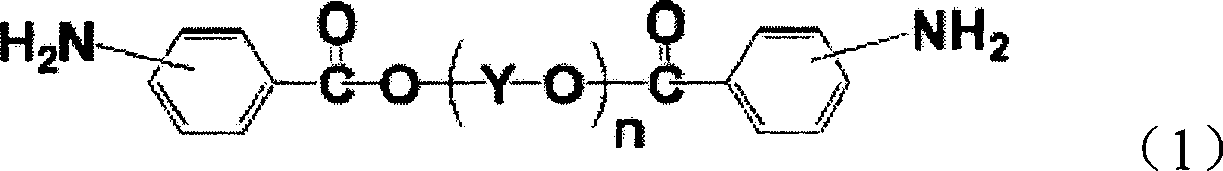

[0155] In a 30 ml five-necked separable flask with a stirrer, a nitrogen inlet tube, a thermometer, and a Dean Stark tube filled with mesitylene, quantitatively add 4,4′-bis(3 -aminophenoxy)biphenyl 17.00g, polytetrahydrofuran-di-p-aminobenzoate (manufactured by Ihara Chemical Industry Co., Ltd., trade name: Erasma-1000, average molecular weight 1305) 40.14g, N-methyl- 86.37 g of 2-pyrrolidone and 37.09 g of mesitylene were heated to 50° C. in a nitrogen atmosphere to dissolve them, and then 25.05 g of oxy-4,4′-diphthalic dianhydride was gradually added in small amounts. Then, a nitrogen gas introduction tube was inserted (foaming state), and the temperature in the system was heated to 170° C. to 180° C. to azeotropically remove water while maintaining it for 10 hours. After cooling, 61.67 g of N-methyl-2-pyrrolidone and 26.49 g of mesitylene were added and diluted to obtain a solution of polyimide (III-1). After making a solution in N-methyl-2-pyrrolidone with a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com