Method for preparing ultra-thin highly-pure lanthanum oxide by beneficiated lanthanum

A technology of enrichment and lanthanum oxide, applied in the direction of improving process efficiency, can solve the problems of high toxicity of oxalic acid, difficulty in improving production capacity, and increase in production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

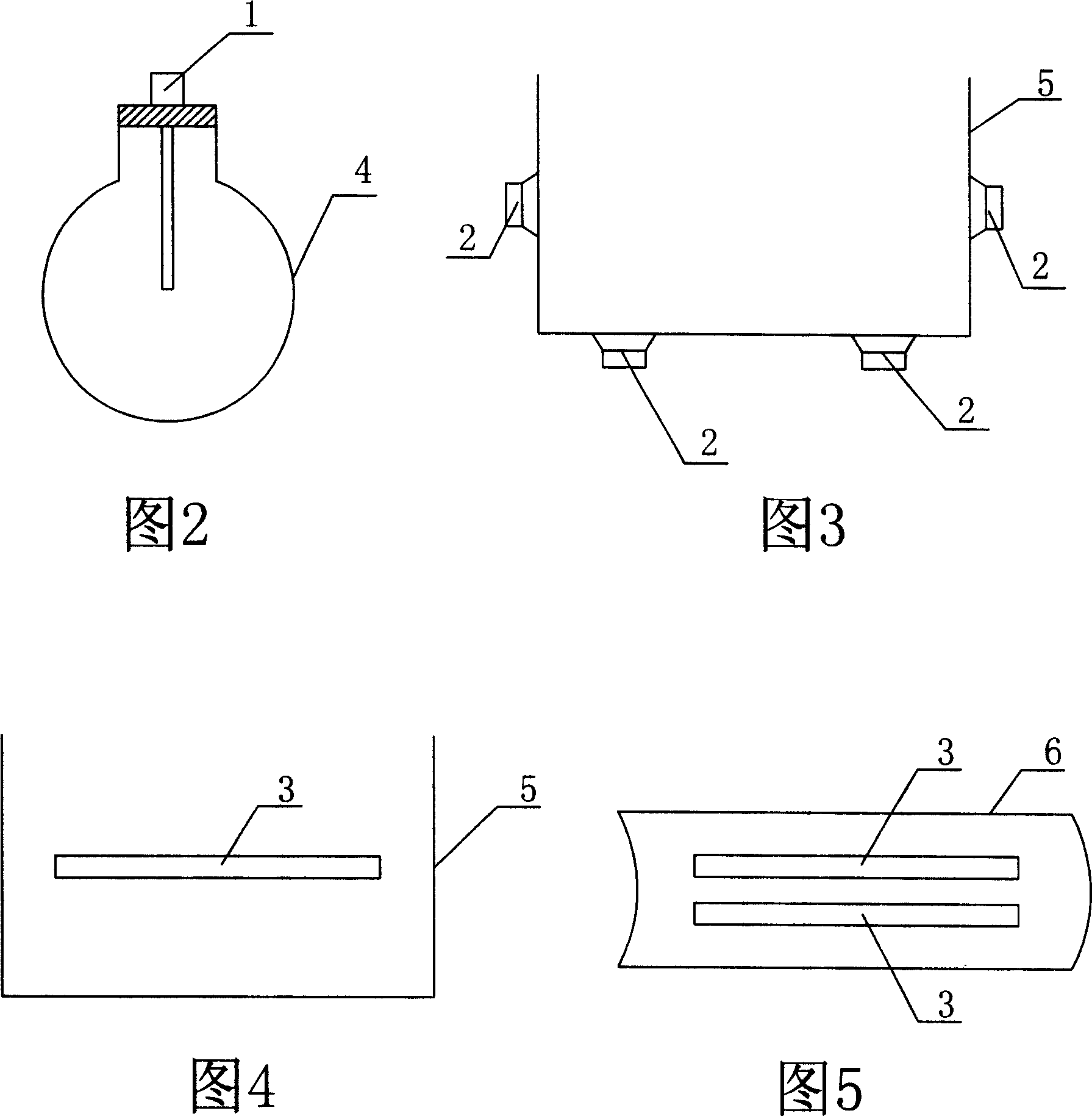

[0024] Main equipment: extraction kettle with probe-type ultrasonic generator, crystallization kettle with probe-type ultrasonic generator.

[0025] Main raw materials: Lanthanum concentrate, HNO 3 , TBP extractant, kerosene, NH 4 HCO 3 .

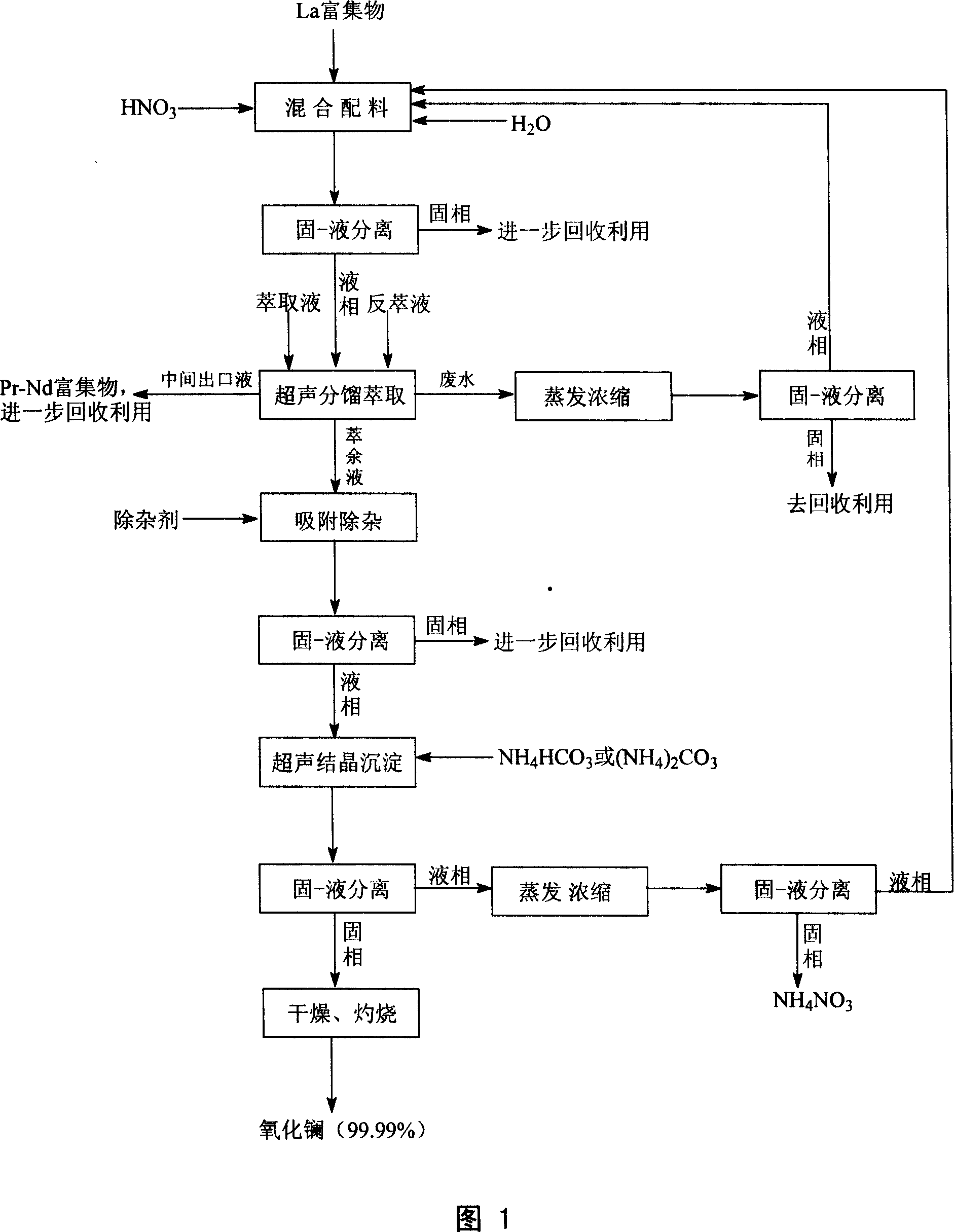

[0026] As shown in Figures 1 and 2, a method for preparing ultrafine high-purity lanthanum oxide from a lanthanum enrichment is to use the lanthanum enrichment as a raw material, and the steps of the method are as follows:

[0027] (1) Mixing ingredients: mixing lanthanum-enriched material, nitric acid, and water, and removing insoluble impurities through solid-liquid separation to obtain lanthanum-enriched material liquid, the concentration of rare earth in the material liquid is 0.1-2.3mol / L;

[0028] (2) Ultrasonic fractionation extraction: In the extraction kettle with a probe-type ultrasonic generator, add lanthanum-enriched material liquid, extraction liquid, and back-extraction liquid. The volume ratio of the three material ingred...

Embodiment 2

[0035] Main equipment: extraction tank with vibrator-type ultrasonic generator, crystallization tank with vibrator-type ultrasonic generator.

[0036] Main raw materials: Lanthanum concentrate, HNO 3 , TBP extractant, sulfonated kerosene, (NH 4 ) 2 CO 3 .

[0037] As shown in Figures 1 and 3, a method for preparing ultrafine high-purity lanthanum oxide from a lanthanum enrichment is to use the lanthanum enrichment as a raw material, and the steps of the method are as follows:

[0038] (1) Mixing ingredients: mixing lanthanum-enriched material, nitric acid, and water, and removing insoluble impurities through solid-liquid separation to obtain lanthanum-enriched material liquid, the concentration of rare earth in the material liquid is 0.1-2.3mol / L;

[0039] (2) Ultrasonic fractionation extraction: In the extraction tank with a vibrator-type ultrasonic generator, add lanthanum-enriched material liquid, extraction liquid, and back-extraction liquid. The volume ratio of the th...

Embodiment 3

[0046] Main equipment: Main equipment: extraction tube with vibrating plate ultrasonic generating device, crystallization tube with vibrating plate ultrasonic generating device.

[0047] Main raw materials: Lanthanum concentrate, HNO 3 , TBP extractant, No. 200 gasoline, NH 4 HCO 3 .

[0048] As shown in Figures 1 and 5, a method for preparing ultrafine high-purity lanthanum oxide from a lanthanum enrichment uses the lanthanum enrichment as a raw material, and the steps of the method are as follows:

[0049] (1) Mixing ingredients: mixing lanthanum-enriched material, nitric acid, and water, and removing insoluble impurities through solid-liquid separation to obtain lanthanum-enriched material liquid, the concentration of rare earth in the material liquid is 0.1-2.3mol / L;

[0050] (2) Ultrasonic fractionation extraction: In the extraction tube with a vibrating plate ultrasonic generator, add lanthanum-enriched material liquid, extraction liquid, and stripping liquid. The volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com