Preparation method of magnetostriction alloy with excellent combined properties

A comprehensive performance, magnetostrictive technology, applied in the direction of material selection for magnetostrictive devices, device material selection, etc., can solve the problem of low magnetostrictive performance, reduce eddy current loss, and expand the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

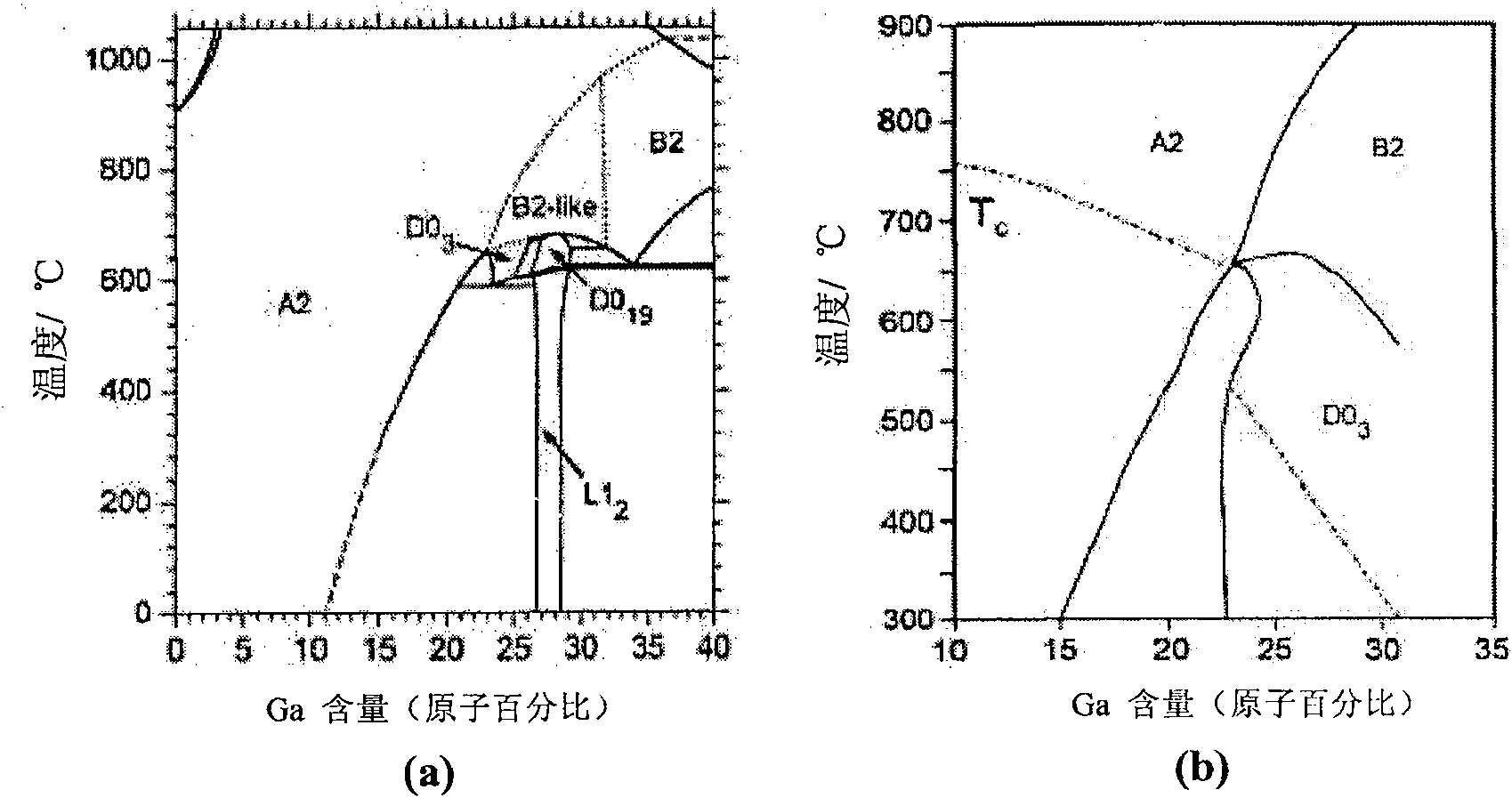

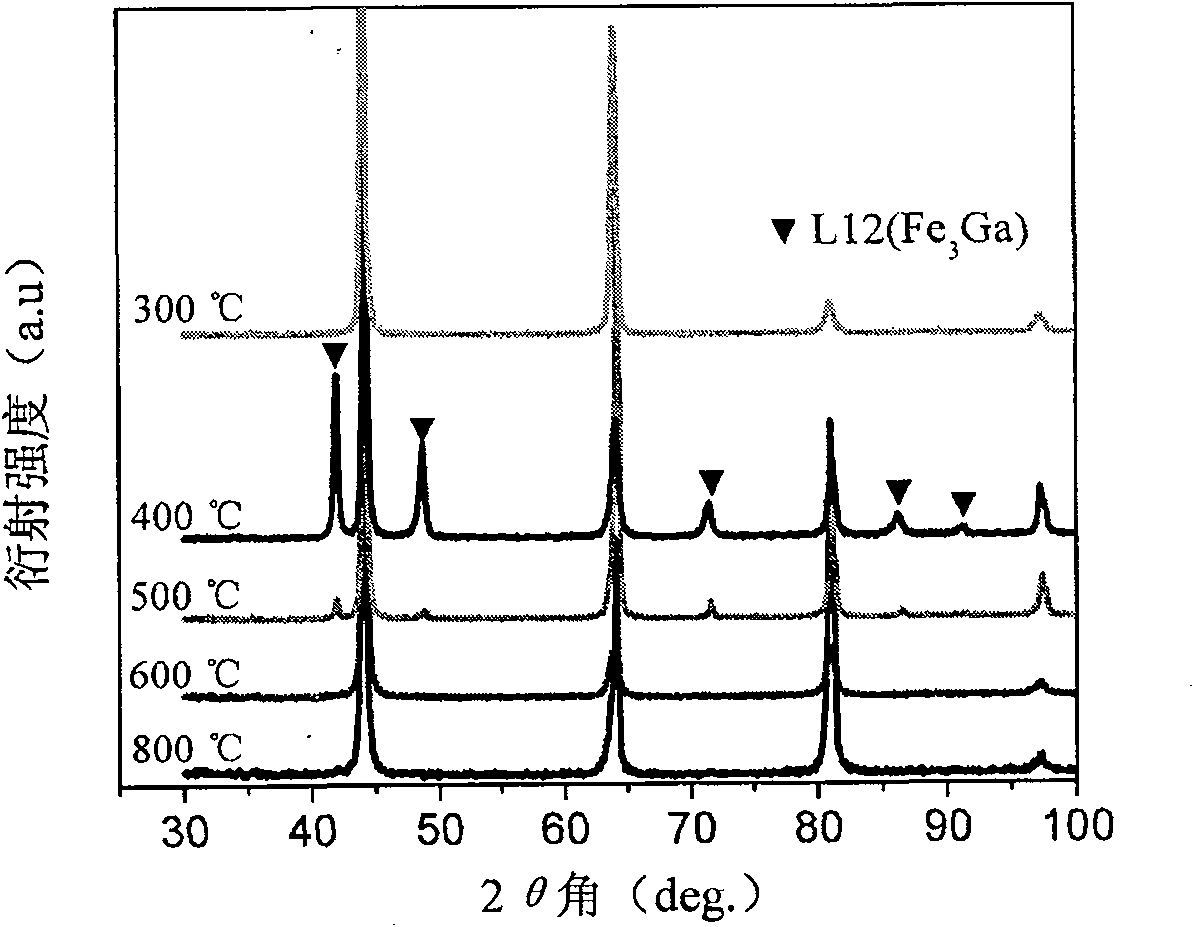

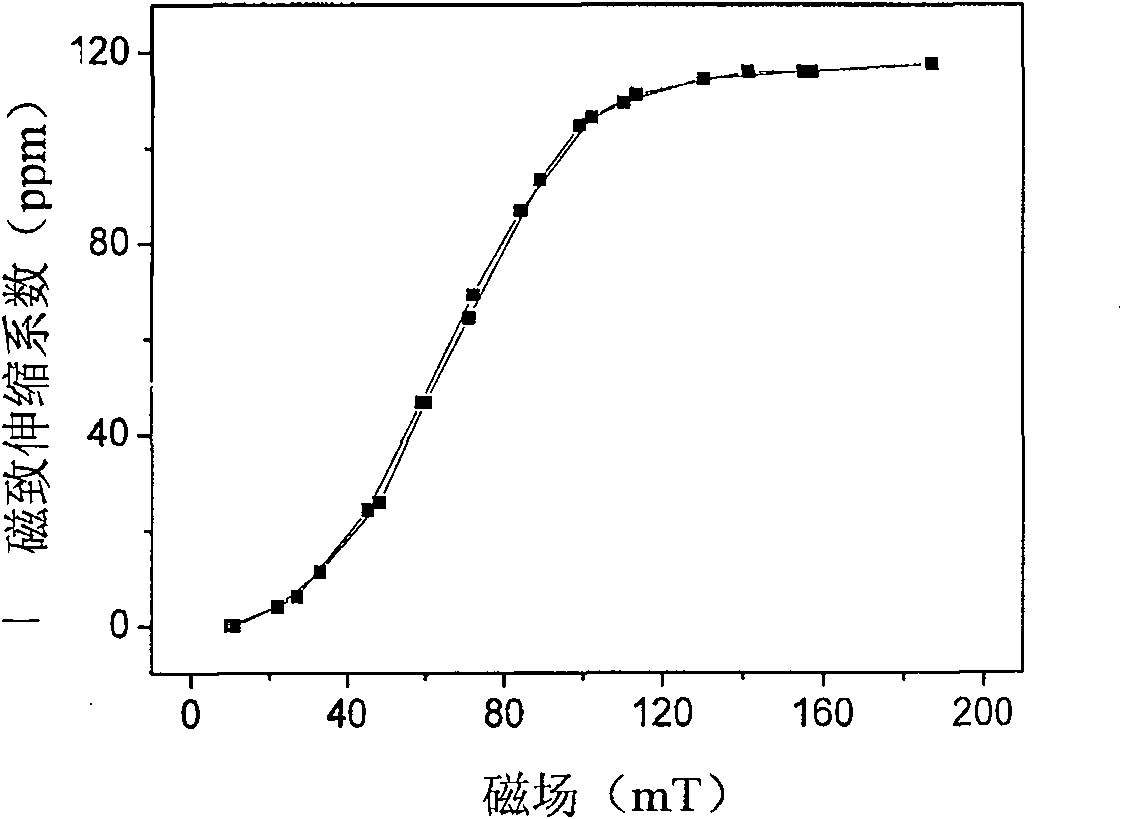

[0020] 1) Smelting cast rods, using Fe and Ga with a purity greater than 99.9wt% as raw materials, weighed according to the atomic percentage of 75:25, put them into a quartz crucible, and adjust the vacuum degree of the vacuum chamber to reach 5×10 -2 ~2×10 -3 Pa, high-purity argon is introduced as protective gas, medium-frequency induction heating is melted and cast into a rod-shaped Fe with a diameter of 12mm in a water-cooled copper mold 75 Ga 25 alloy ingot. ;

[0021] 2) The composition is homogenized, and the smelted Fe 75 Ga 25 The alloy ingot is kept at 1000°C for 168h for a long time, and then cooled with the furnace;

[0022] 3) multi-stage heat treatment, the homogenized Fe 75 Ga 25 After the alloy ingot is vacuum packaged, it is heated to 1000°C, kept for 3h, cooled to 200°C at a furnace cooling rate of 0.9°C / min, kept for 3h, and then water quenched to room temperature.

[0023] Table 1: Fe prepared by this method 75 Ga 25 Polycrystalline alloy and Fe p...

Embodiment 2

[0027] 1) Smelting and casting rods, using Fe and Ga with a purity greater than 99.9wt% as raw materials, weighed according to the atomic percentage of 81:19, put them into a quartz crucible, and adjust the vacuum degree of the vacuum chamber to reach 5×10 -2 ~2×10 -3 Pa, high-purity argon is introduced as protective gas, medium-frequency induction heating is melted and cast into a rod-shaped Fe with a diameter of 12mm in a water-cooled copper mold 81 Ga 19 alloy ingot;

[0028] 2) The composition is homogenized, and the smelted Fe 81 Ga 19 The alloy ingot is kept at 1000°C for 24 hours for a long time, and then cooled with the furnace;

[0029] 3) multi-stage heat treatment, the homogenized Fe 81 Ga 19 After the alloy ingot is vacuum packaged, it is heated to 1000°C, kept for 0.5h, cooled to 300°C at a furnace cooling rate of 0.45°C / min, kept for 0.1h, and then water quenched to room temperature.

[0030] Table 2: Fe prepared by this method 81 Ga 19Polycrystalline al...

Embodiment 3

[0034] 1) Smelting and casting rods, using Fe and Ga with a purity greater than 99.9wt% as raw materials, weighed according to the atomic percentage of 81:19, put them into a quartz crucible, and adjust the vacuum degree of the vacuum chamber to reach 5×10 -2 ~2×10 -3 Pa, high-purity argon is introduced as protective gas, medium-frequency induction heating is melted and cast into a rod-shaped Fe with a diameter of 12mm in a water-cooled copper mold 81 Ga 19 alloy ingot;

[0035] 2) The composition is homogenized, and the smelted Fe 81 Ga 19 The alloy ingot is kept at 1100°C for 72 hours for a long time, and then cooled with the furnace;

[0036] 3) multi-stage heat treatment, the homogenized Fe 81 Ga 19 After the alloy ingot was vacuum packaged, it was heated to 800°C, kept for 5 hours, cooled to 100°C at a furnace cooling rate of 0.17°C / min and held for 6 hours, and then water quenched to room temperature.

[0037] Table 3: Fe prepared by this method 81 Ga 19 Polycry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com