Low-temperature hydrothermal method for manufacturing zinc oxide nanocrystalline whisker

A zinc oxide nanocrystal, low temperature technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, single crystal growth and other directions, can solve the problems of high cost, complex technology and process, and achieve low cost, simple operation, The effect of eliminating high temperature sintering and ball milling processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Weigh an appropriate amount of Zn(CH 3 COO) 2 2H 2 O and NaOH, in molar ratio [OH - ]:[Zn] is 11:1 to prepare uniform Zn(OH) 4 2- aqueous solution;

[0016] 2) Add 10ml of Zn(OH) 4 2- Add the aqueous solution to 65ml of glycerin and water in a composite solvent with a volume ratio of 13:5, then add 2g / L polyacrylamide, heat and magnetically stir at 90°C until completely dissolved, and continue ultrasonic oscillation for 30min;

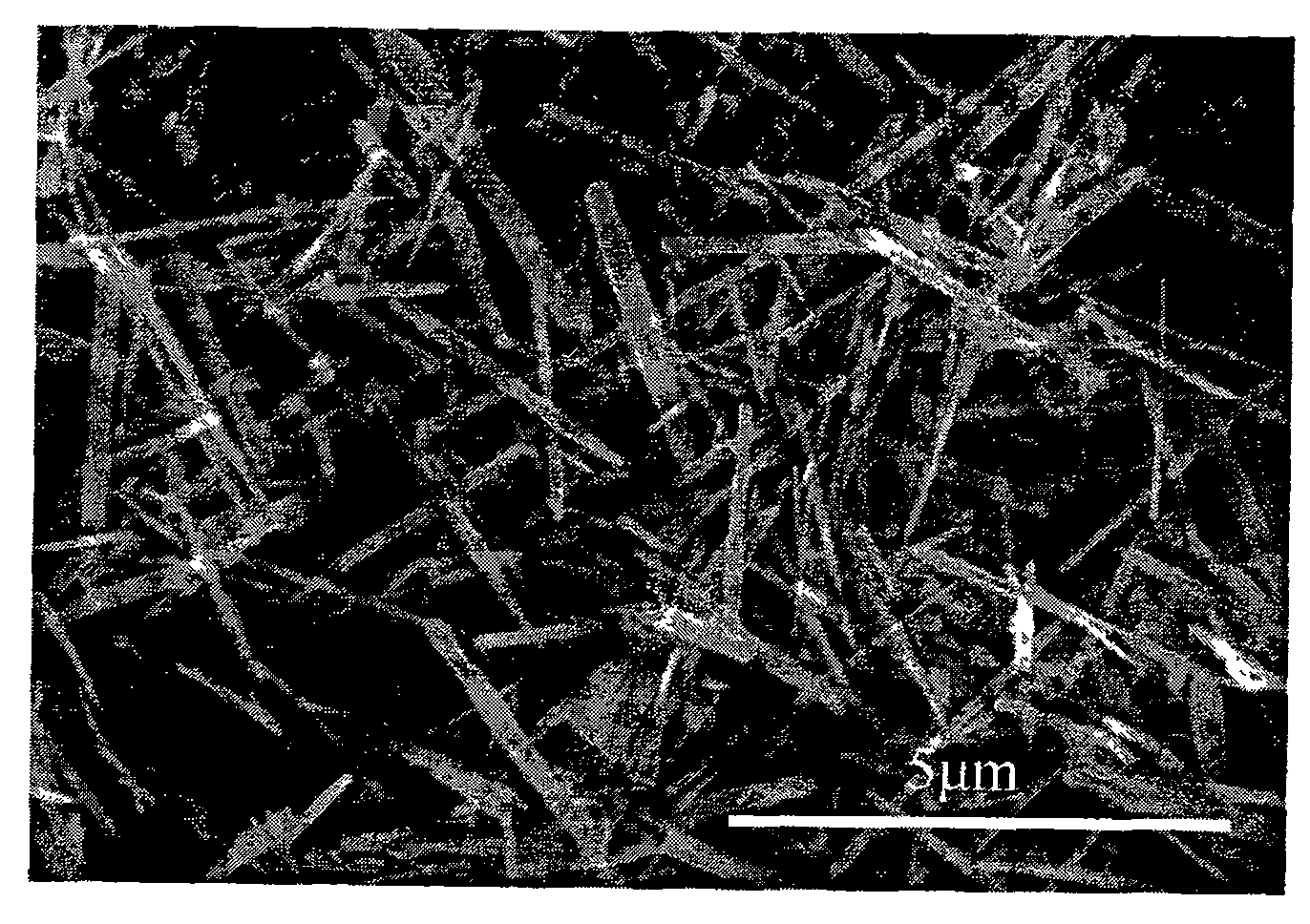

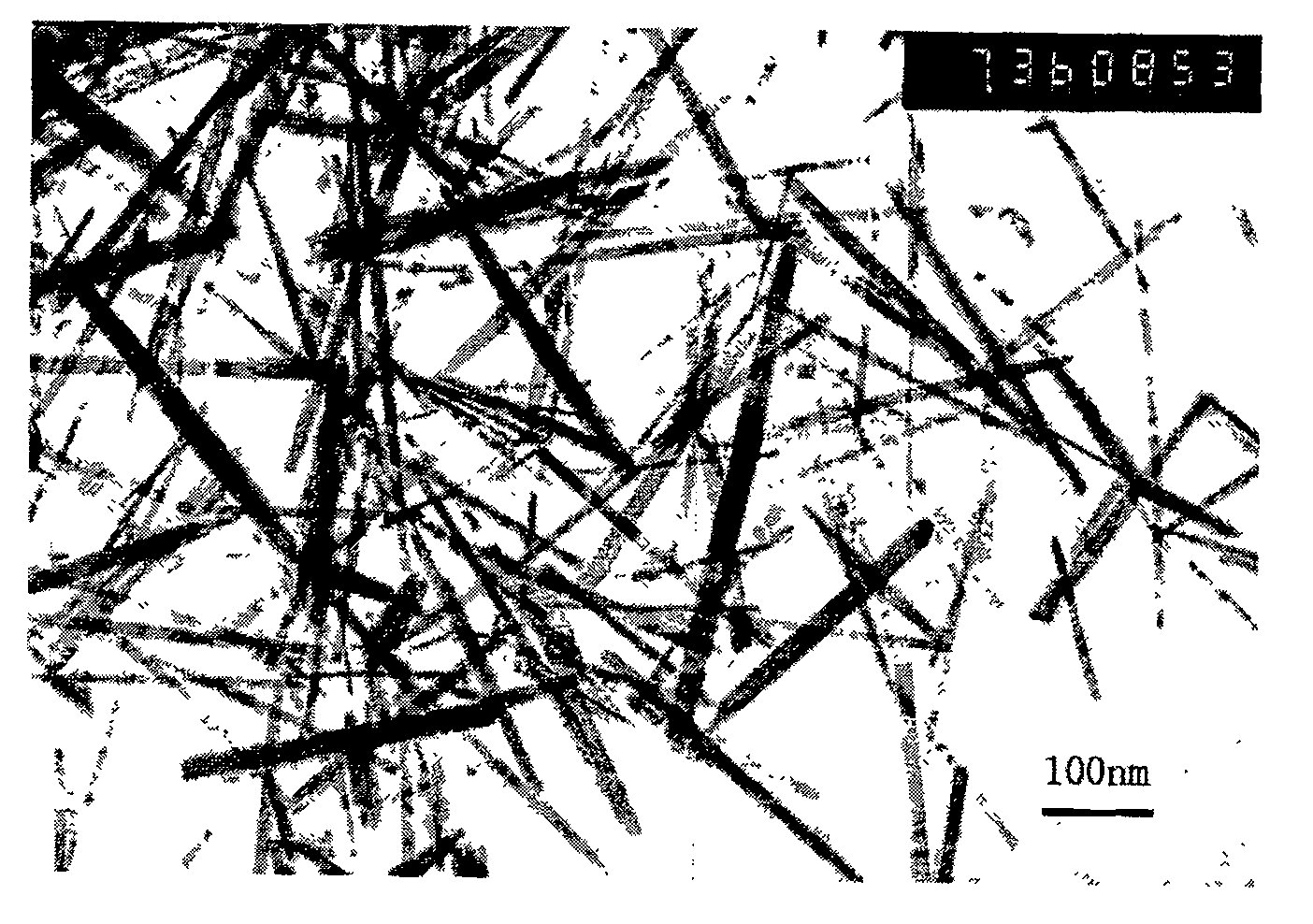

[0017] 3) Place the solution prepared in step 2) in a polytetrafluoroethylene-lined autoclave, seal it, and react at 180°C for 20 hours. After the reaction is completed, cool to room temperature, centrifuge and wash repeatedly with deionized water, and then heat the solution at 90°C. Dry under vacuum for 5 h. Zinc oxide nano whiskers were obtained. Nanowhisker structure see figure 1 with figure 2 shown.

Embodiment 2

[0019] 1) Weigh an appropriate amount of Zn(NO 3 ) 2 and NaOH, in molar ratio [OH - ]:[Zn] is 10:1 to prepare uniform Zn(OH) 4 2- aqueous solution;

[0020] 2) Add 10ml of Zn(OH) 4 2- Add the aqueous solution to 70ml of glycerin and water in a composite solvent with a volume ratio of 13:5, then add 3g / L polyacrylamide, heat and magnetically stir at 90°C until completely dissolved, and continue ultrasonic oscillation for 30min;

[0021] 3) Place the solution prepared in step 2) in a polytetrafluoroethylene-lined autoclave, seal it, and react at 190°C for 18 hours. After the reaction is completed, cool to room temperature, centrifuge and wash repeatedly with deionized water, and then heat the solution at 90°C. Dry under vacuum for 5 hours to obtain zinc oxide nano whiskers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com