Method and equipment for manufacturing metal parts directly by using electrodeposition technique of laminated template

A technology of metal parts and electrodeposition, applied in the direction of electroforming, electrolysis, etc., can solve the problems of inability to directly prepare complex shapes and precision, inability to obtain large-sized and complex-shaped metal parts, and large investment in equipment, achieving good application prospects, The effect of low processing cost and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

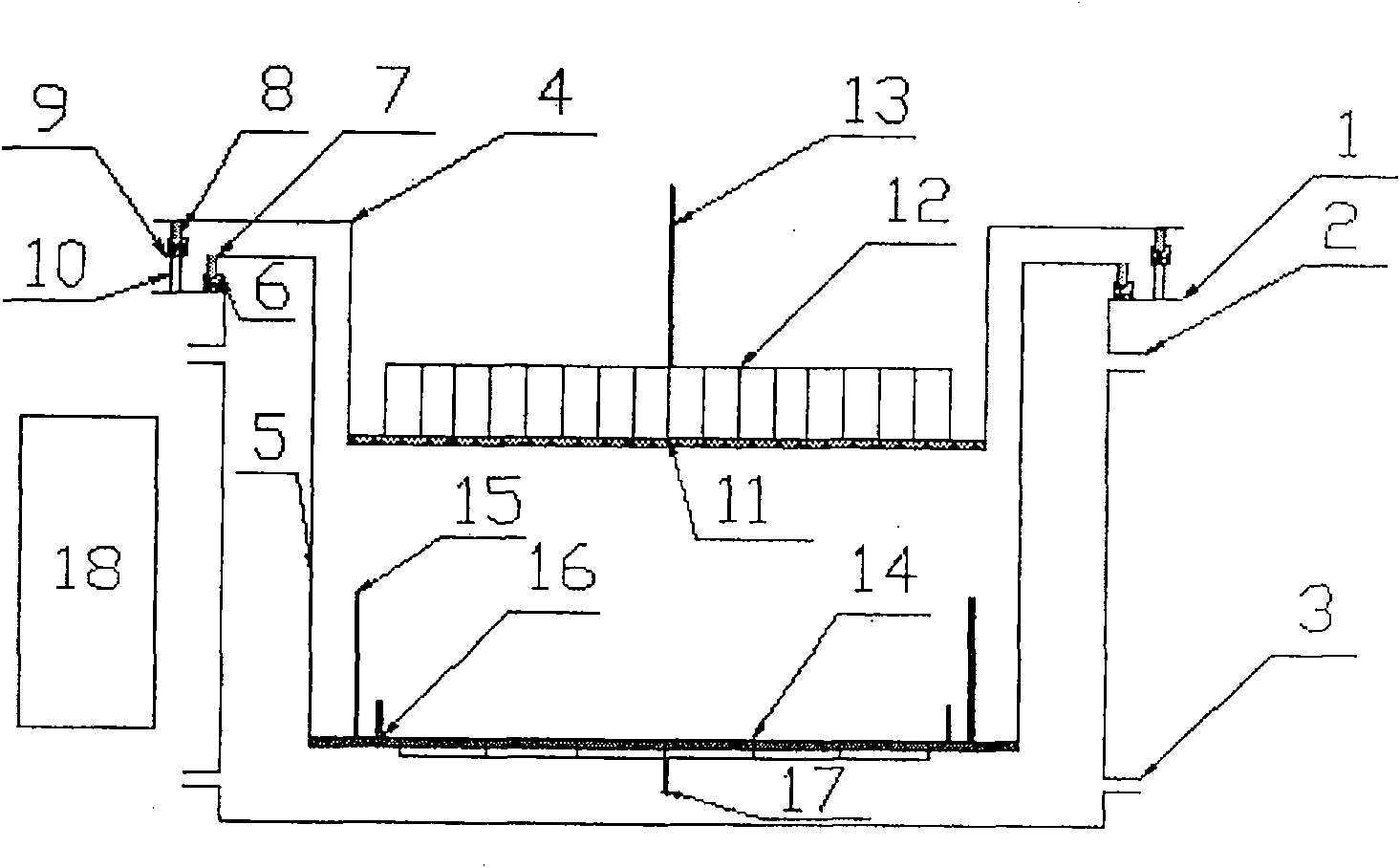

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

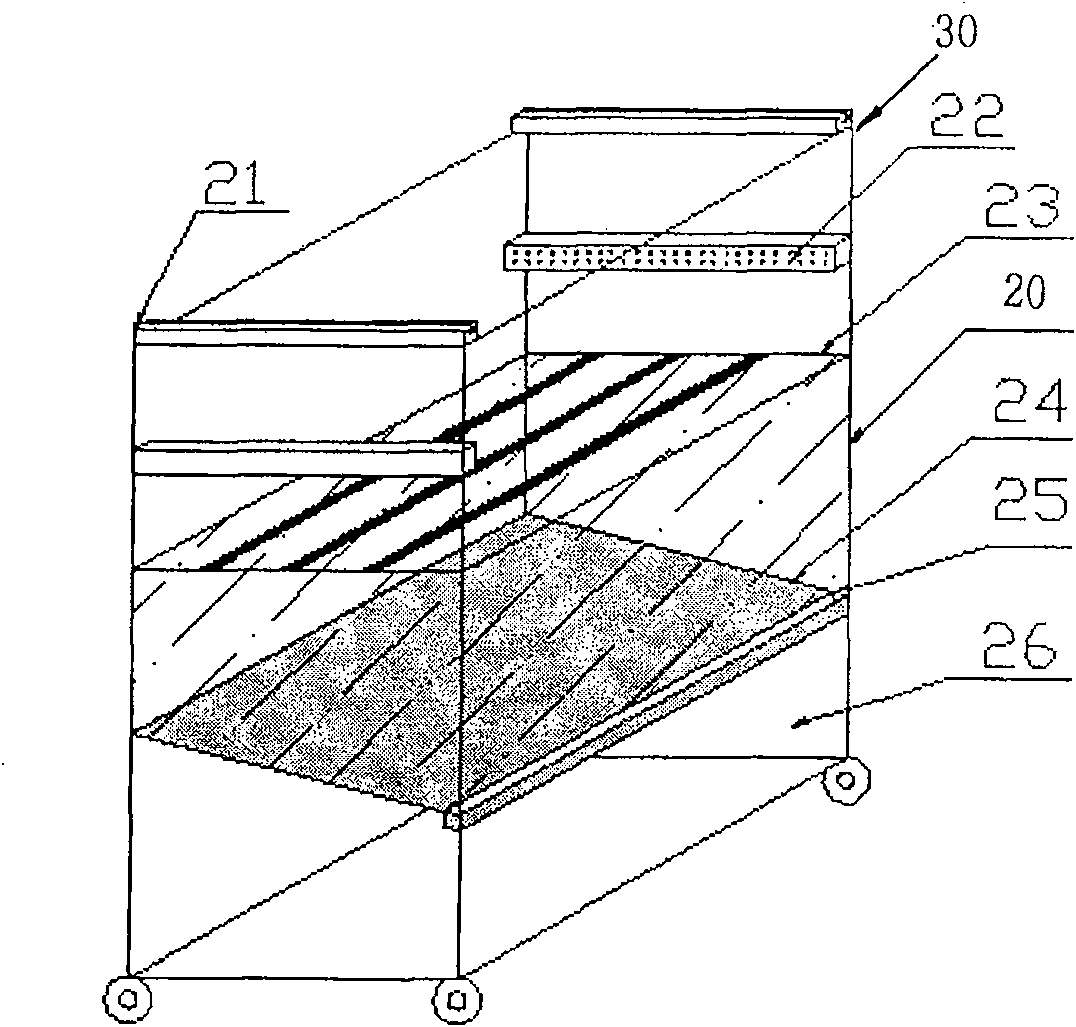

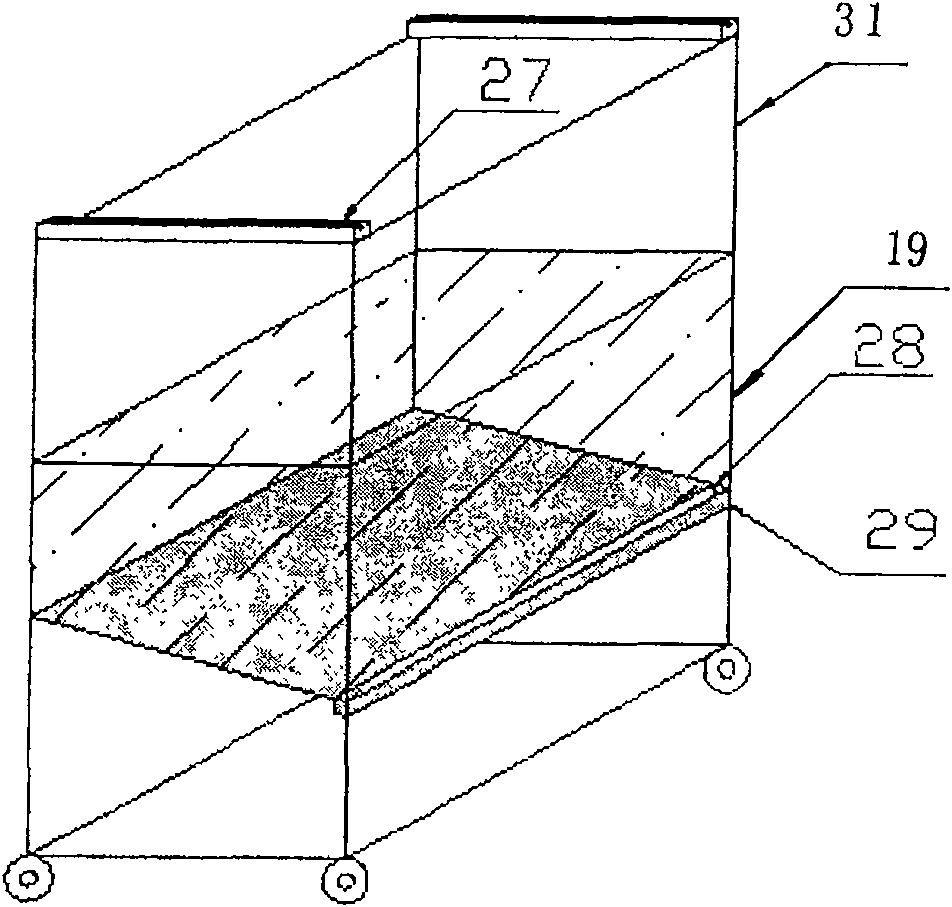

[0019] Such as Figure 4 shown.

[0020] A method for directly manufacturing metal parts using stacked template electrodeposition technology, comprising the following steps:

[0021] First, use CAD modeling software to design the solid shape of the metal parts;

[0022] Then the CAD file in solid modeling (i.e. STL) format is processed by slicing software and saved as n layer-slicing numerical control files, and the single-layer path information is input into the cutting machine and then cut to obtain n layer-slicing templates;

[0023] Third, install the first layer template on the base electrode of the cathode tray of the electrodeposition forming system with the cathode tray and the anode tray for metal electrodeposition. After the deposition of the first layer template is completed, the anode The tray is moved out to the anode tray working platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com