Nano inner core sandwich type structural silica dioxide delustring agent and preparation method thereof

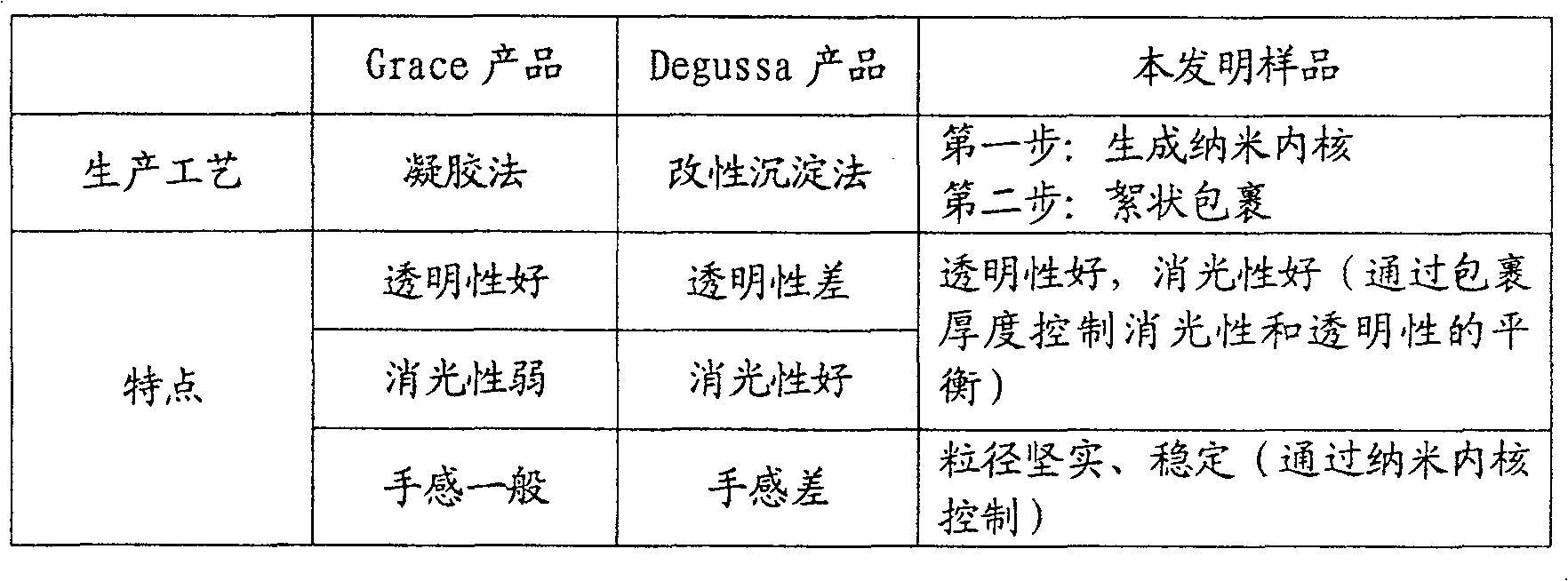

A silica and matting agent technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of low porosity, poor transparency, high porosity, etc., achieve good matting performance, not easy to settle, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Pass 1L of 10% silicate solution through ion exchange resin for ion exchange, then adjust the pH of the reaction solution to 2.5, age at 60°C for 2h, and then add it to the reactor containing 15% silicate solution under stirring conditions Adjust the pH to 9 and keep it for 1 hour after the addition is complete to prepare the nano silica core; while stirring, the temperature is raised to 80°C, and 15% sodium silicate solution and 7% hydrochloric acid solution are added dropwise at the same time, by controlling the acid The pH of the reaction system was adjusted to 8.5 by the dropping amount, and the temperature was kept for 1 hour after the dropping. Filter, wash, surface treatment with polymer. Spray drying equipment is used to remove the moisture contained in silica, and a supersonic jet mill is used to crush the silica to 3 microns.

Embodiment 2

[0038]The silica matting agent was prepared basically according to the same method as described in Example 1, but the difference from Example 1 was that the temperature was raised to 70° C. under stirring, and then 10% sodium silicate solution and hydrochloric acid solution were added.

Embodiment 3

[0040] The silica matting agent was prepared basically in the same manner as described in Example 1, but the difference from Example 1 was that 10% sodium silicate solution and 7% nitric acid solution were added dropwise at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com