Vertical type highly effective energy-saving abrasion-proof pump

An anti-corrosion and high-efficiency technology, applied in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems of long self-priming time, long running time and high noise of vertical self-priming pumps, and achieve no The effect of long fault running time, beautiful appearance and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

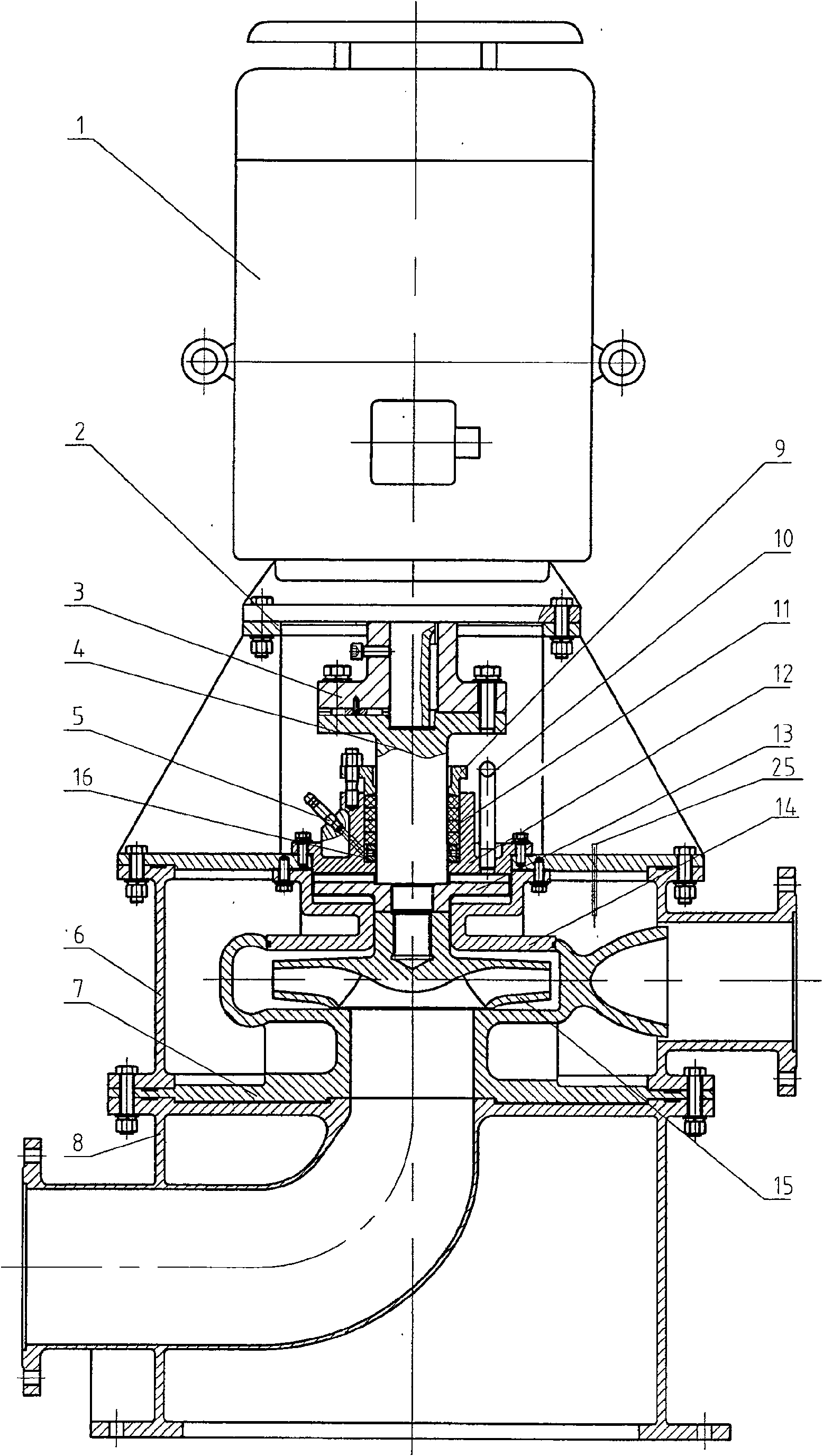

[0022] figure 1 Among them, the upper end of the upper pump body 6 is connected with the motor 1 installed on the motor bracket 2, the lower end of the upper pump body 6 is connected with the volute 7 and the lower pump body 8, and the side is a discharge pipe. Inside the upper pump body 6 are a volute 7 , an impeller 15 , a sealing body 12 and a decompression impeller 13 . The motor 1 is connected to the pump shaft 4 through a rigid coupling 3. The bottom of the pump shaft 4 is equipped with an impeller 15, and the upper part of the impeller 15 is a decompression impeller 13, which is fixed on the pump shaft 4. The pump shaft 4 passes through the water seal ring 16, The sealing packing 11 and the sealing gland 9 are connected with the motor coupling 3 . The sealing body 12 is fixedly connected with the motor support 2 at the upper end of the upper pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com