Energy-saving type grain microwave insect preventing and mould-proof method and special equipment

A kind of anti-mildew technology for grains, which is applied in the direction of trapping or killing insects, application, preservation of seeds through radiation/electrical treatment, etc., can solve the problems of tarnish and beauty, high cooling speed, surface cracks, etc. The effect of enhanced thermal effect, improved heat transfer efficiency, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (basic test method and equipment example):

[0044] 1. Test materials and equipment

[0045] The grains used in the experiment were paddy and rice produced in China (the variety is Jinyou 207, provided by Hunan Jinjian Rice Industry Co., Ltd.). The common storage insects are rice elephant, saw-saw thieves, and red-thick thorax, which were donated by Henan University of Technology. The analysis and detection instrument is a near-infrared grain quality analyzer (Perten 9100 / 01, produced in Germany).

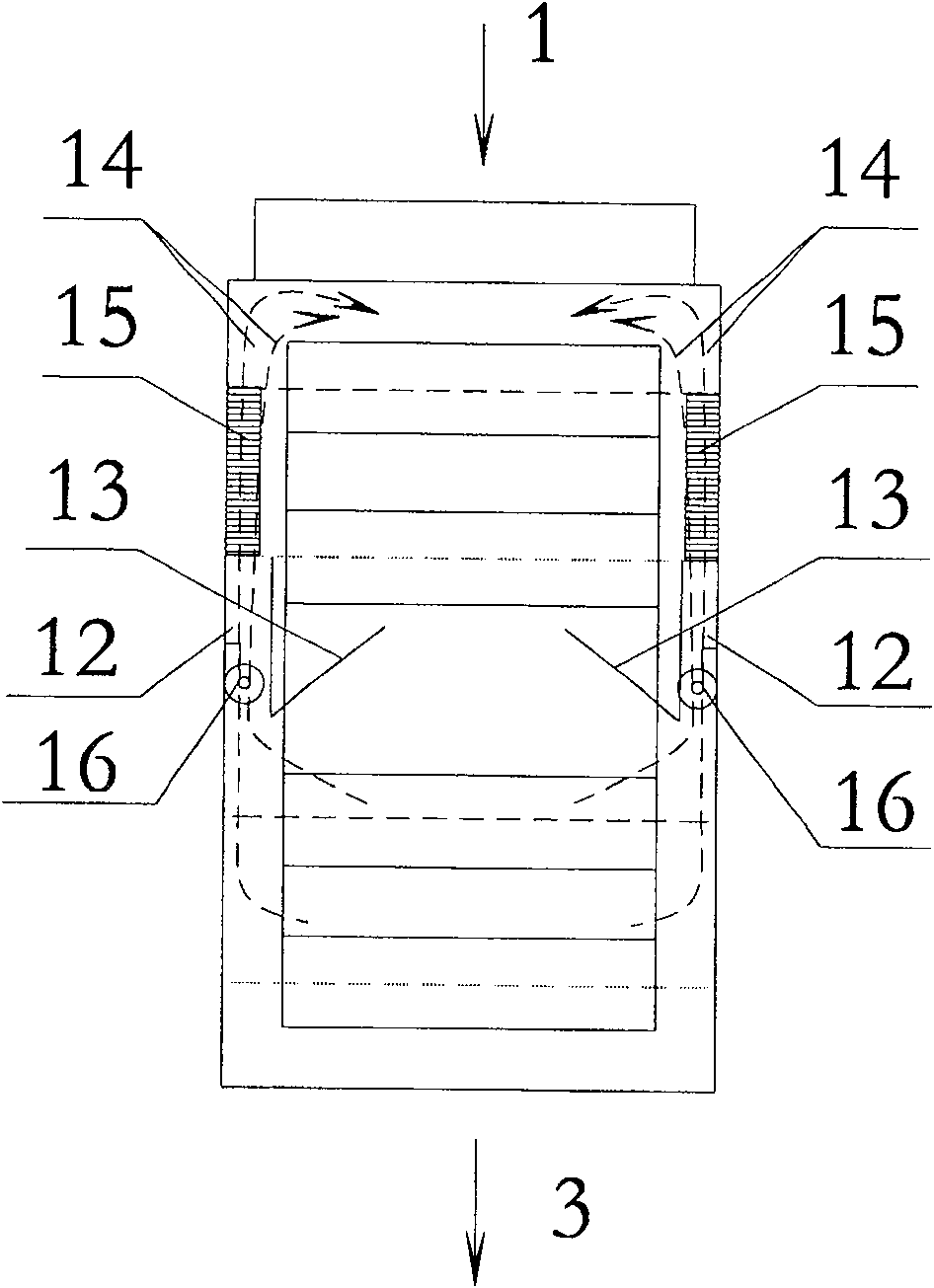

[0046] The microwave oven of the present invention adopts an industrial microwave oven, model: QW-15HM type, 2450MHz, output power 24KW, produced by Guangzhou Kewei Microwave Energy Co., Ltd. The effective size (the accumulation volume of rice in the microwave oven) is 4680mm×600mm×60mm (length×width×height).

[0047] 2. Test method:

[0048] (1) Sample preparation

[0049] 1) Inject 20 live and healthy test insects (rice elephant, saw-saw beetle, and red-s...

Embodiment 2

[0075] Embodiment 2 (special equipment of the present invention and process parameter example):

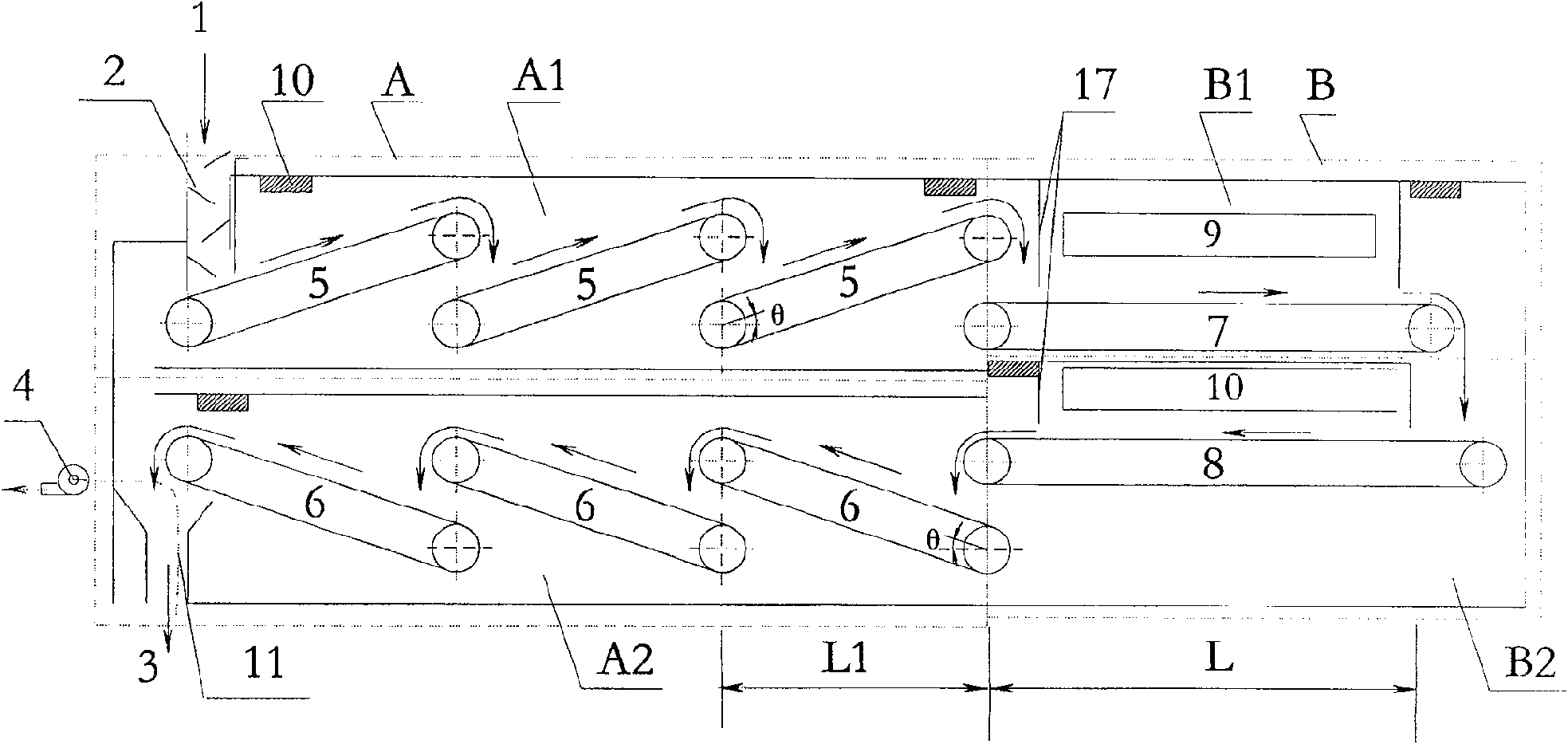

[0076] attached by figure 1 , 2 As shown, the processing equipment of the present invention includes processing units A and B, wherein the projected length L1 of the belt conveyors (5), (6) in processing unit A is L1=2m, and the actual length is 2.263m. The belt width is 600mm, the quantity is 3, and the inclination angle θ=20°. The rotating speed of belt conveyors 5 and 6 is 399 rpm, and the residence time of rice in A1 and A2 is 8 minutes respectively.

[0077] The belt conveyor (7) in the processing unit B has a length L=3m and a width of 600mm; the belt conveyor (8) has a length of 3.3m and a width of 600mm. The rotating speed of belt conveyor (7), (8) 375 turns / min. The total time of microwave treatment (B1 and B2) was 5 min. Microwave output power is 13.125kw;

[0078] The total length of the microwave device is 9.8m, the total width is 0.7m, and the total height is 3...

Embodiment 3

[0086] Embodiment 3 (invention effect example):

[0087] In order to obtain the best implementation mode of the present invention, applicant comparatively designed 1#-17# series test, through reagent test and test, its main technical parameters are as follows:

[0088] Microwave output power: P=13.125kw;

[0089] Rice flow rate is 820kg / h; irradiation quality is 85.3kg (rice), 71.6kg (paddy);

[0090] The specific heat of rice is 1.96kJ / kg·℃; the heat loss is 5%; the microwave dose (power) is 0.15kw / kg;

[0091] The initial temperature of rice is 38°C; the material thickness is 50±2mm; the material width is 500±2mm;

[0092] The total length L=7.2m that is used for irradiation treatment in the microwave oven of experiment; When the rotating speed of belt conveyor (7) and (8) 300,375,400 turns / min, corresponding microwave treatment time is 4,5,6min respectively.

[0093] Table 1 shows the preheating air temperature 45°C-50°C, time 8-12min, so that the rice temperature after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com