Heat pipe and radiating model group

A heat dissipation module and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problems of slowing down the circulation speed of working fluid and reducing the heat transfer performance of heat pipe 10, etc., to achieve Effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A heat pipe and heat dissipation module will be further described in detail below with reference to the drawings and embodiments.

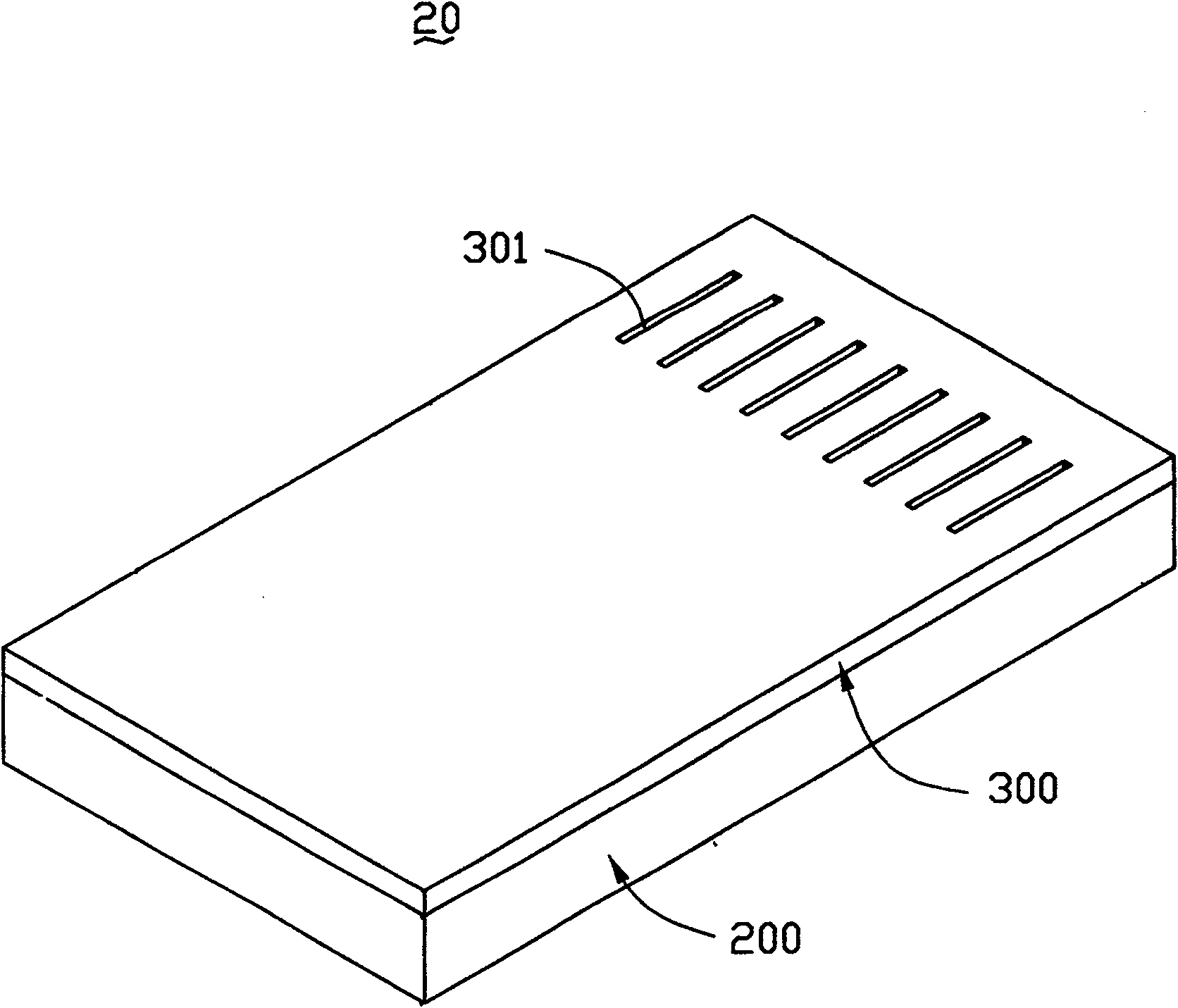

[0016] Such as image 3 and Figure 4 As shown, the heat pipe 20 of the first embodiment of the present invention includes a body 200, a cover 300 matched with it, and a working fluid 400 dispersed in the body 200. The shape of the body 200 can be rectangular, square or other regular. or irregular shape; the shape of the cover body 300 may be the same as that of the main body, or different, as long as the two cooperate to seal the working fluid; Low liquid substances, such as water, ethanol, acetone, etc., and nanoparticles such as nano-copper particles can be added to the working fluid 400 to improve its thermal conductivity.

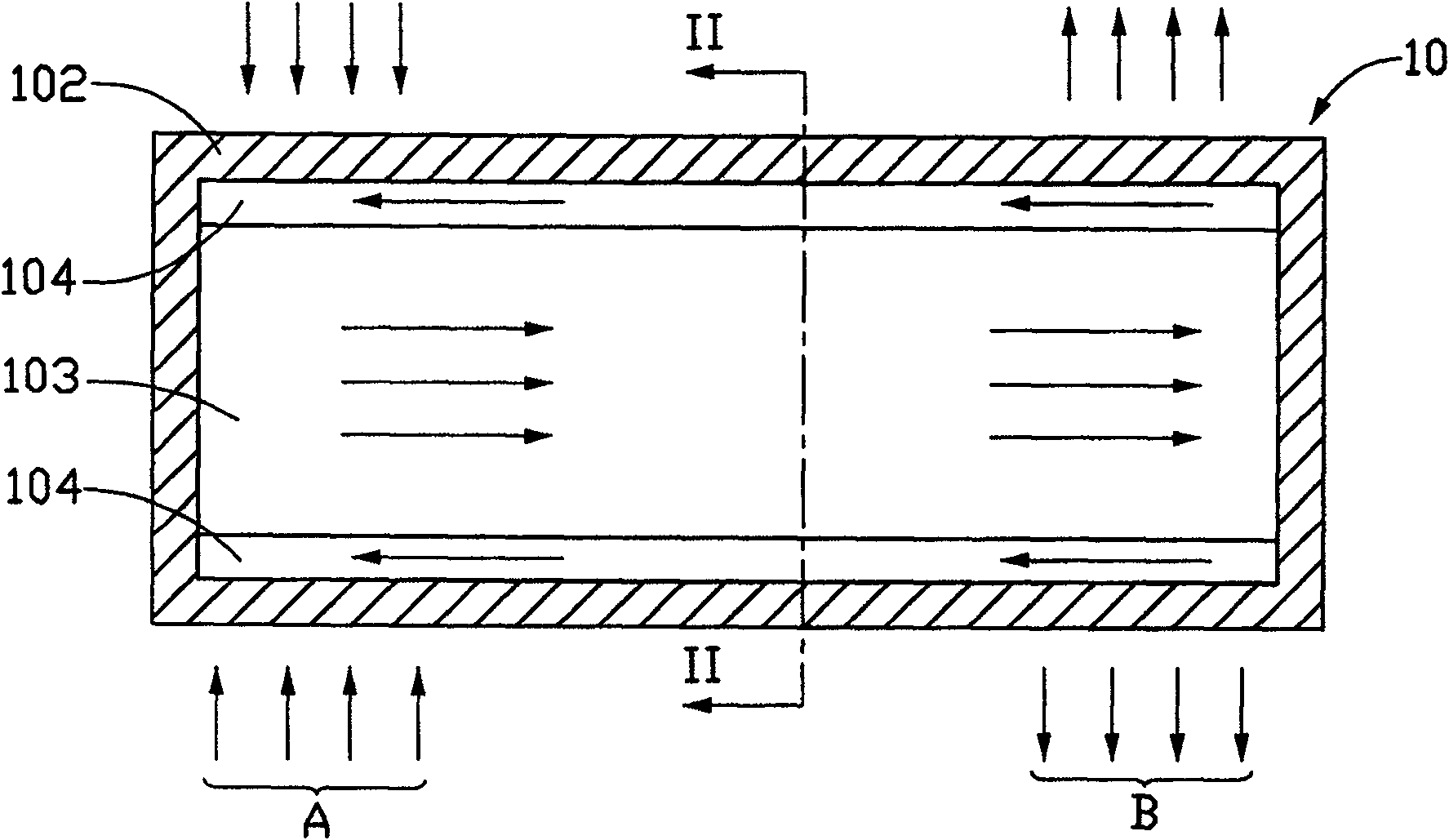

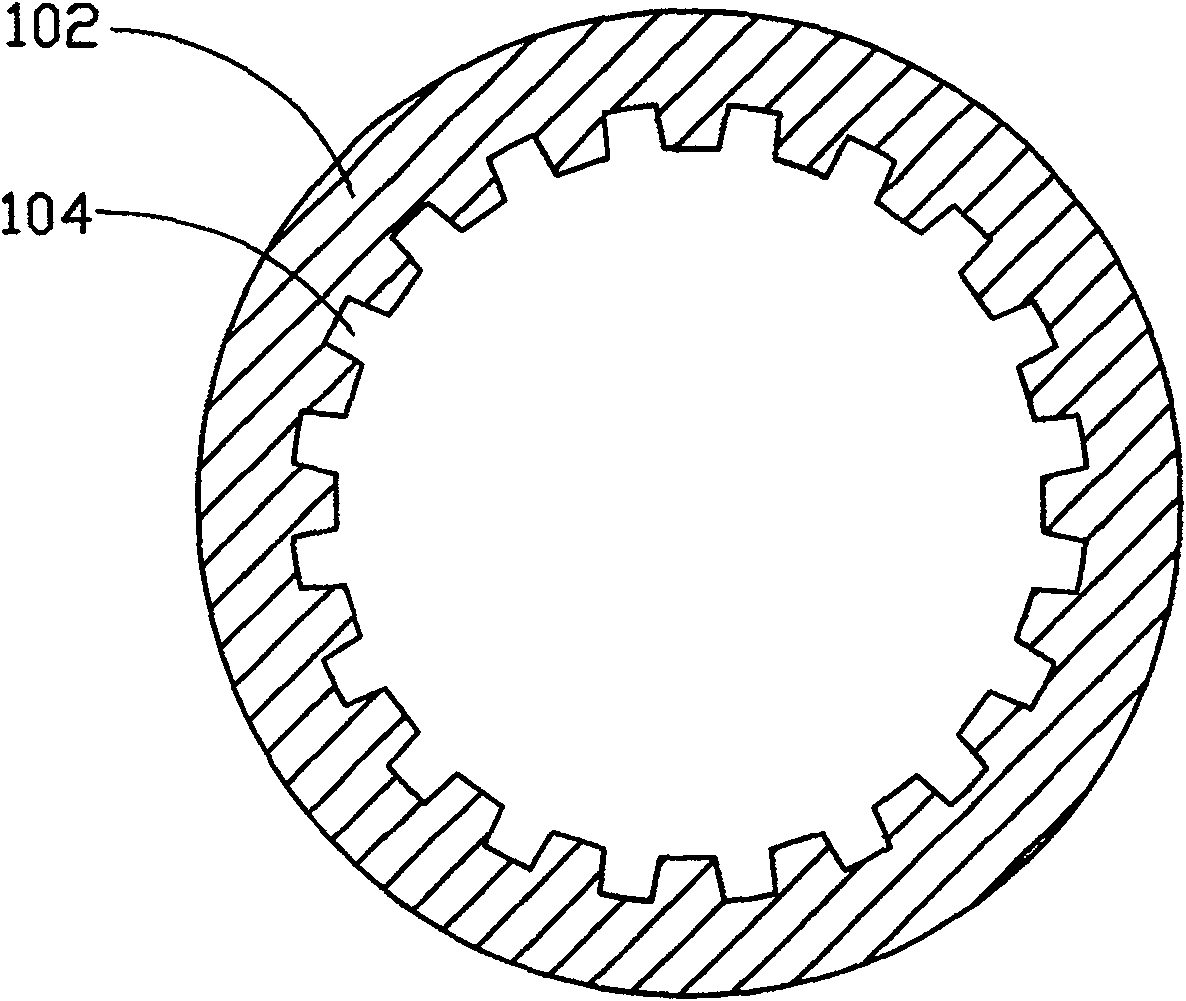

[0017] The body 200 includes an evaporation chamber 210, a condensation chamber 220, an evaporation channel 230 and a return channel 240, the evaporation chamber 210 includes a steam output side 212 and a liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com