Preparation process of nanometer monocrystalline zinc oxide film material

A nano-film material, zinc oxide single crystal technology, applied in the field of optoelectronic materials, can solve the problems of complex equipment and process, high cost, and achieve the effect of reducing injection cost, good quality and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Zn with an energy of 200keV + Injected into quartz glass, the injection dose is 2×10 17 ions / cm 2 .

[0017] The injected sample was annealed in the air at 750°C for 1 hour in an ordinary annealing furnace, and the heating rate was 20°C / min. When the temperature reached 700°C, the Zn atoms in the sample gradually evaporated to the surface of the sample and reacted with oxygen in the air. ZnO is formed on the surface. Incubate at 750°C for 1 hour so that all the Zn atoms in the substrate evaporate to the surface of the substrate. Cool down naturally after annealing.

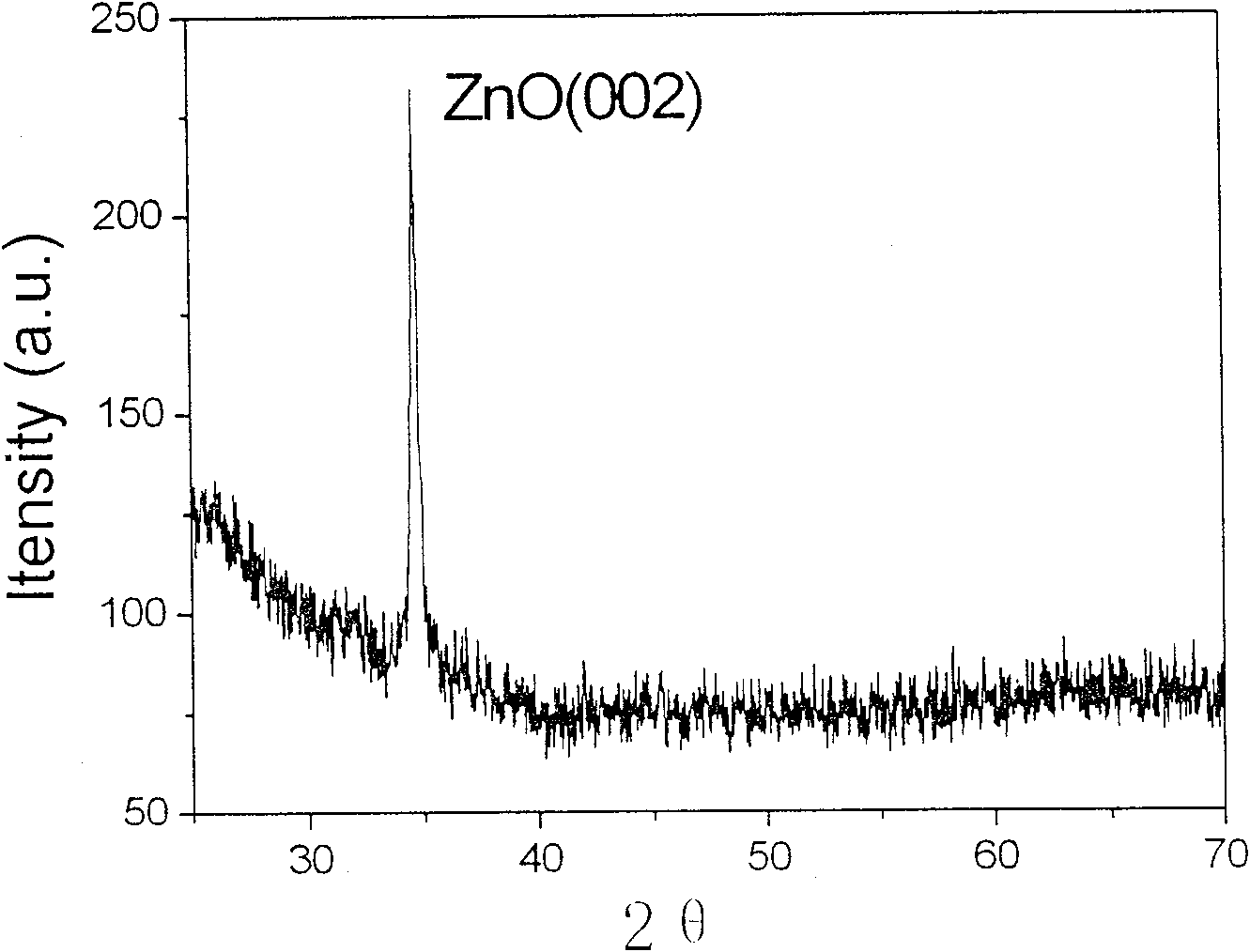

[0018] Analyze the sample prepared in this embodiment, figure 1 It is the X-ray diffraction (XRD) curve of the zinc oxide single crystal nano film prepared by this example, only (002) plane diffraction peak is shown in the figure, shows that the film grows along the c-axis direction, and has very high quality.

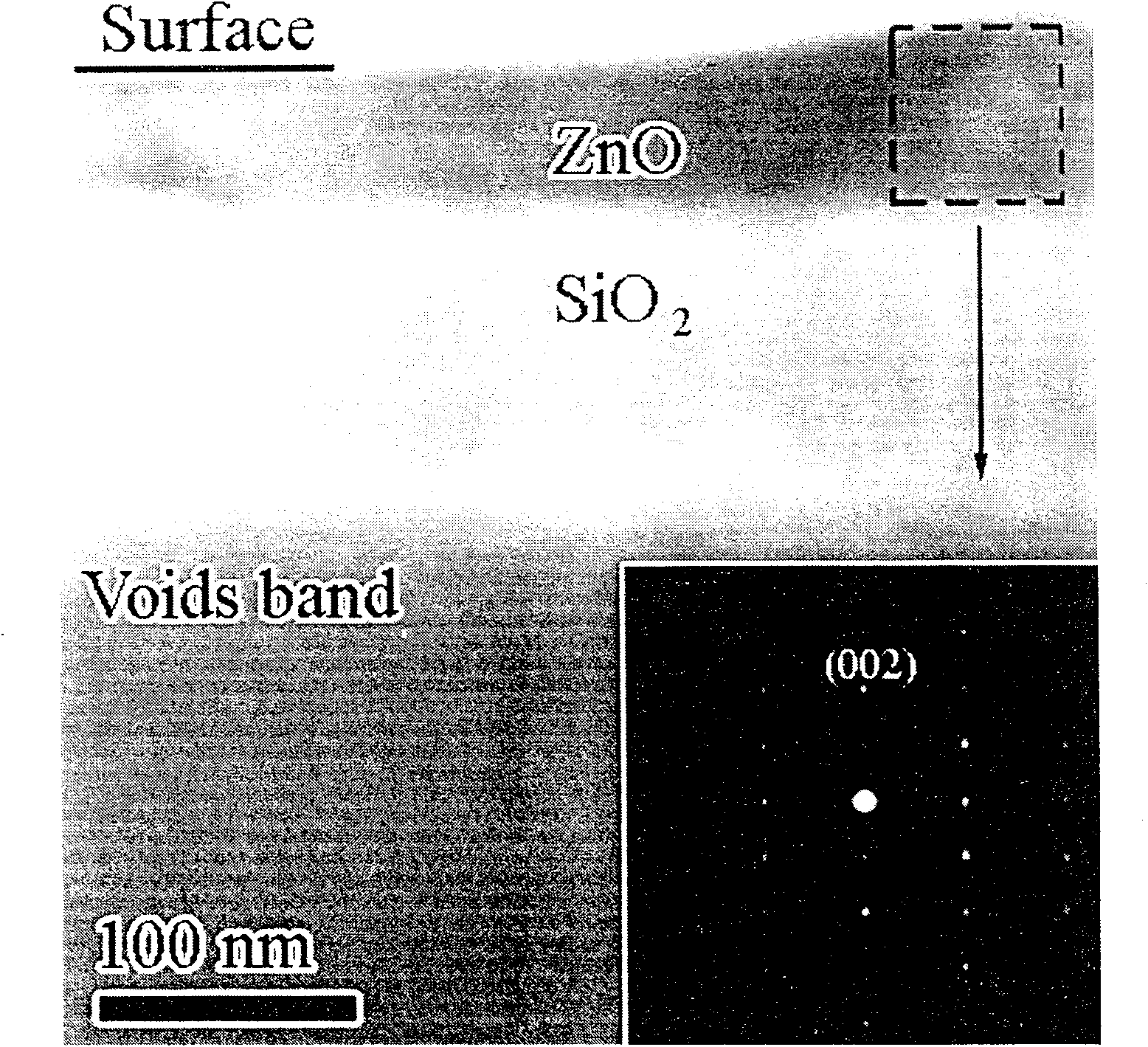

[0019] figure 2 It is the transmission electron microscope (TEM) cross-sectional image a...

Embodiment 2

[0021] Zn with an energy of 50keV + Inject into quartz glass with MEVVA source implanter, the injection dose is 3×10 17 ions / cm 2 .

[0022] The injected sample was annealed in the air at 700°C for 2 hours in a common annealing furnace, and the heating rate was 10°C / min. When the temperature reached 700°C, the Zn atoms in the sample gradually evaporated to the surface of the sample and reacted with oxygen in the air. ZnO is formed on the surface. Keep the temperature at 700°C for 2 hours so that all the Zn atoms in the substrate evaporate to the surface of the substrate. Cool down naturally after annealing.

[0023] The sample prepared in this embodiment was analyzed, and the X-ray diffraction (XRD) curve and transmission electron microscope (TEM) cross-sectional image of the sample also proved that a ZnO single crystal nano film was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com