Wheat bran twin-screw extruding treatment method and twin-screw extruding machine thereof

A twin-screw extrusion and twin-screw extruder technology, which is applied in the directions of food forming, food science, and application, can solve the problems of lack of guidance in the processing of wheat bran and the general effect of processing and processing of wheat bran, and achieve easy Digestion and absorption, low production cost, beneficial effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

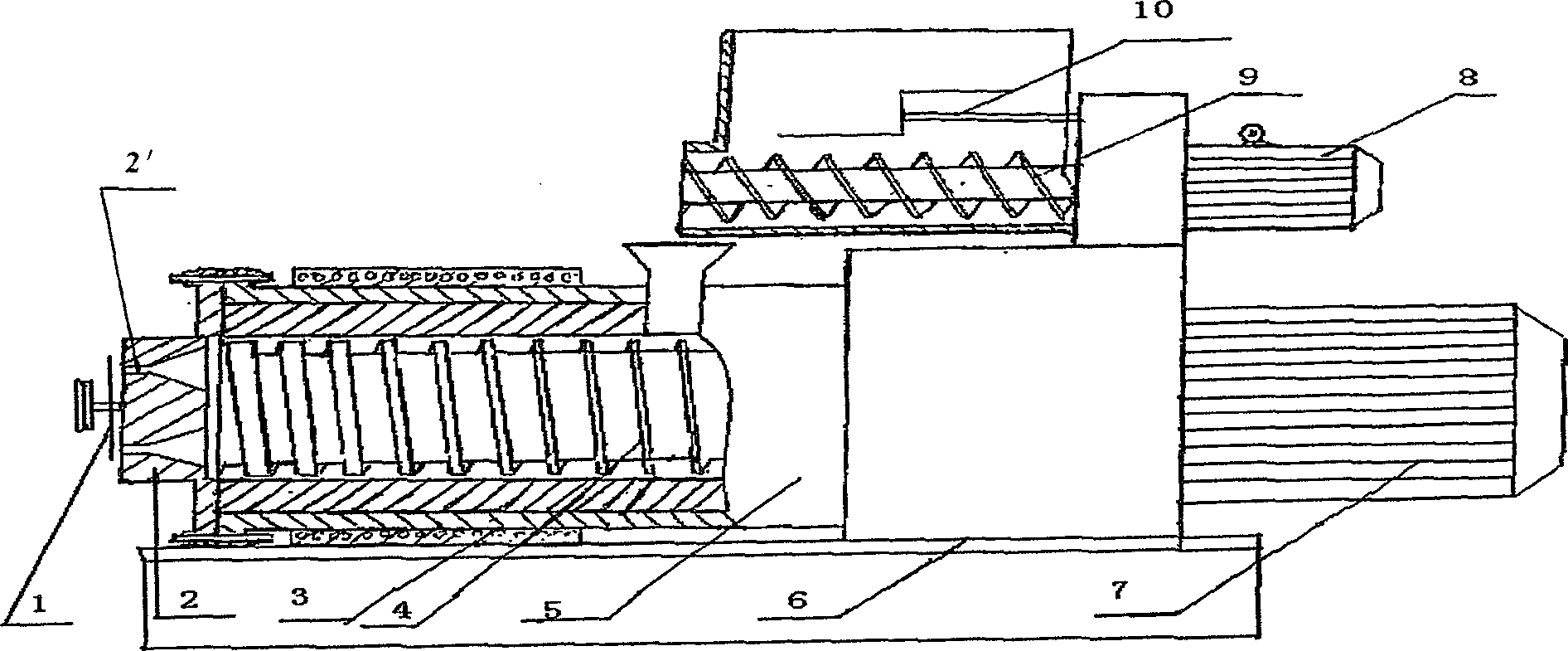

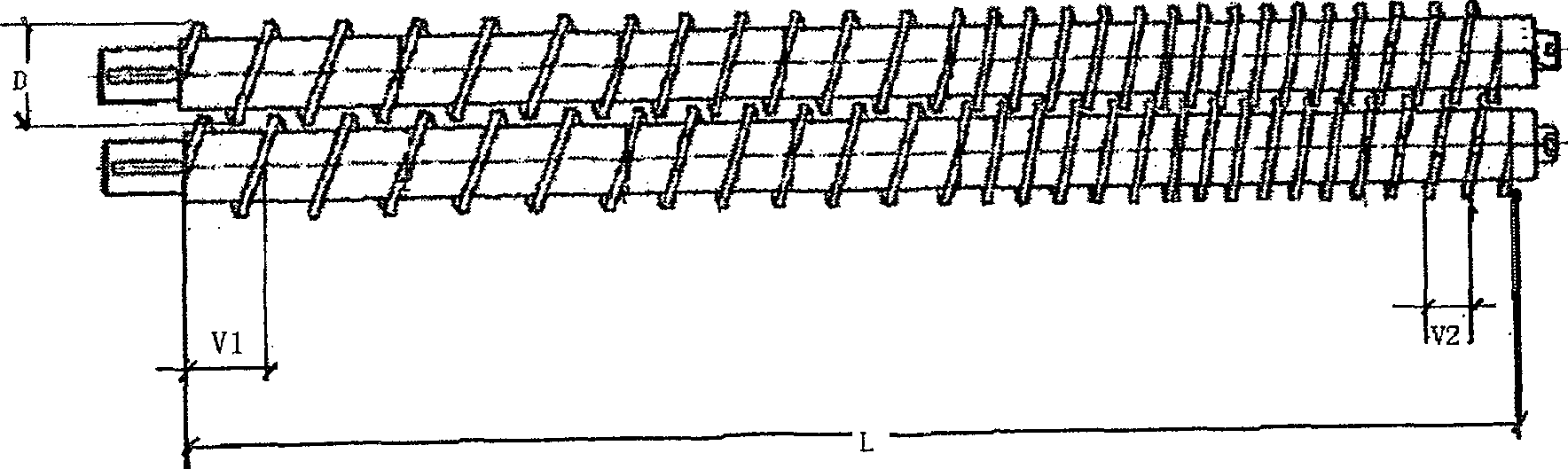

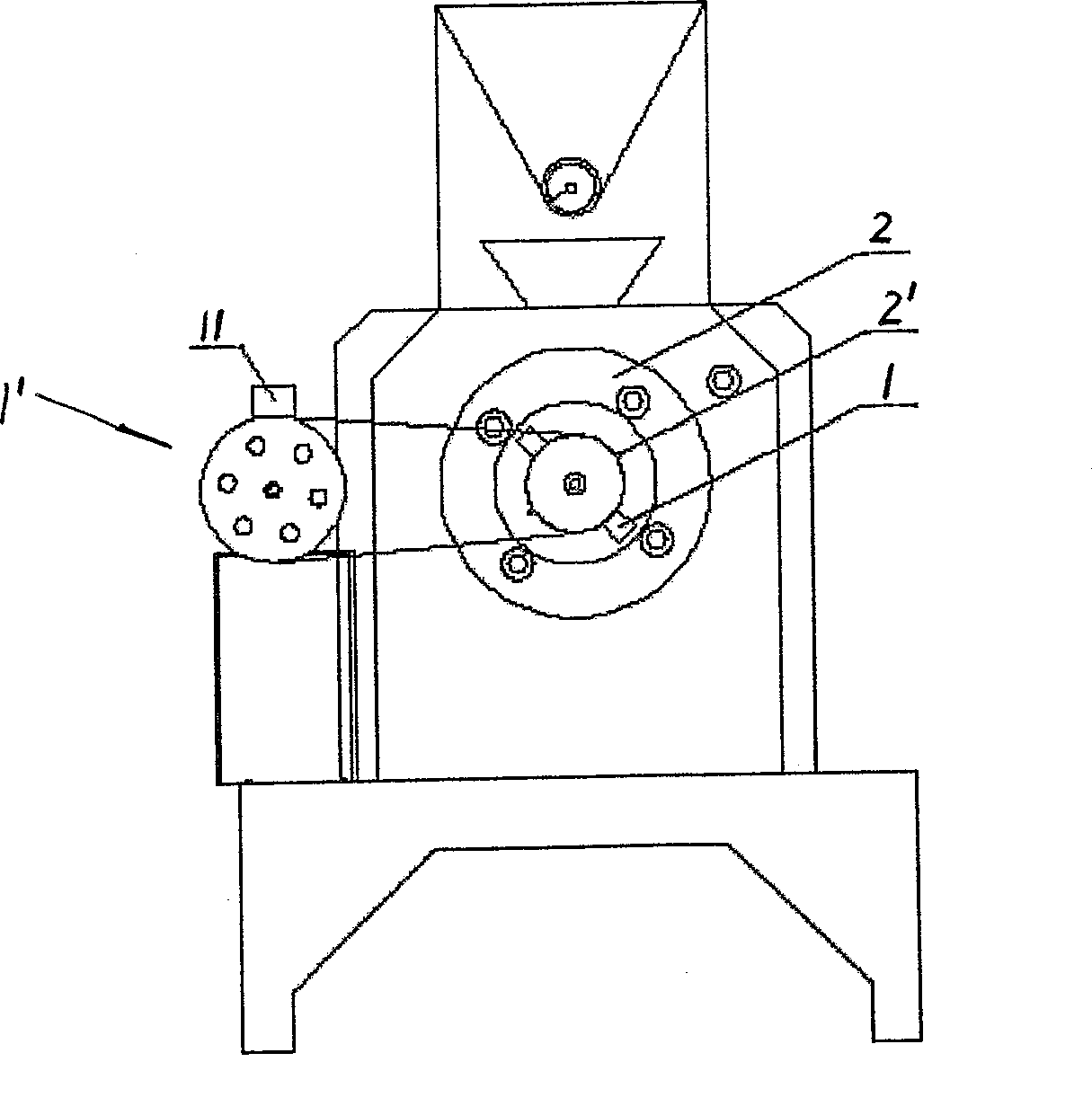

[0028]The twin-screw extrusion processing method of wheat bran includes the following steps: (1) Wheat bran conditioning: using a mixer, first add (extracted from the wheat flour milling workshop) 40-60 mesh (pure) wheat bran Bran, then add 10-15% (optional 12%) (pure) water or food-grade sodium hydroxide solution with a concentration of 3-8% (optional 5%) accounting for the weight of wheat bran, and mix and stir for 3-6 minutes , mix well. (2) Extrusion treatment: Extrude the tempered wheat bran by using a co-rotating full-mesh twin-screw extruder. The working parameters of the twin-screw extruder are: the screw length-to-diameter ratio (L / D) is 15-30:1 (optionally 15:1 or 20:1 or 25:1 or 30:1), wherein, L is the effective length of the screw, and D is the diameter (major diameter) of the screw. The compression ratio (V1 / V2) of the twin-screw is 2 to 8:1 (optional 2:1 or 5:1 or 8:1), where V1 is the volume of the screw groove of one pitch of the screw at the feeding end, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com