Wiring substrate of a semiconductor component comprising external contact pads for external contacts and method for producing the same

A technology for wiring substrates and contact pads, applied in semiconductor/solid-state device components, semiconductor devices, electric solid-state devices, etc., can solve problems such as being unsuitable for mass production, concentration, and complex costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

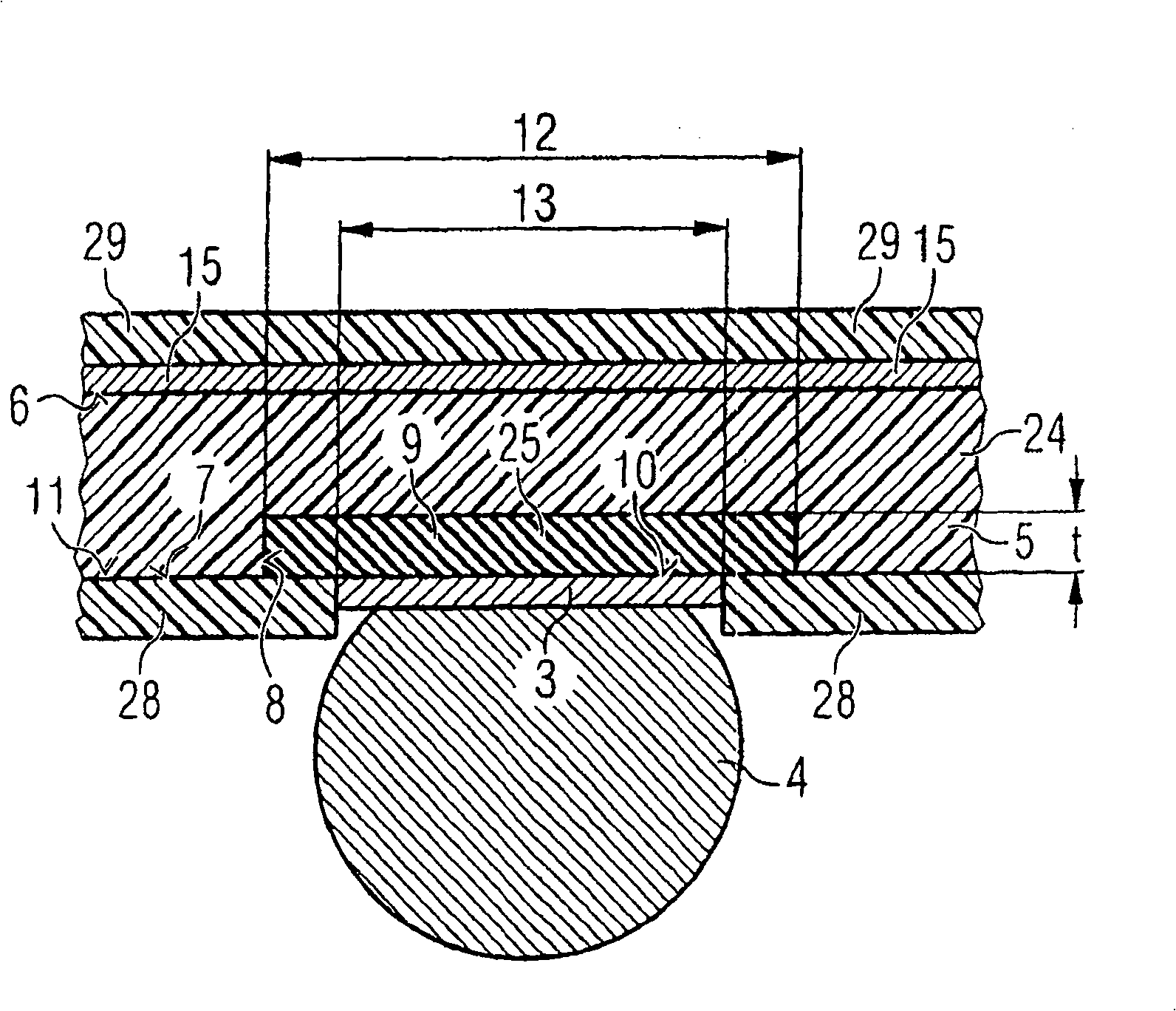

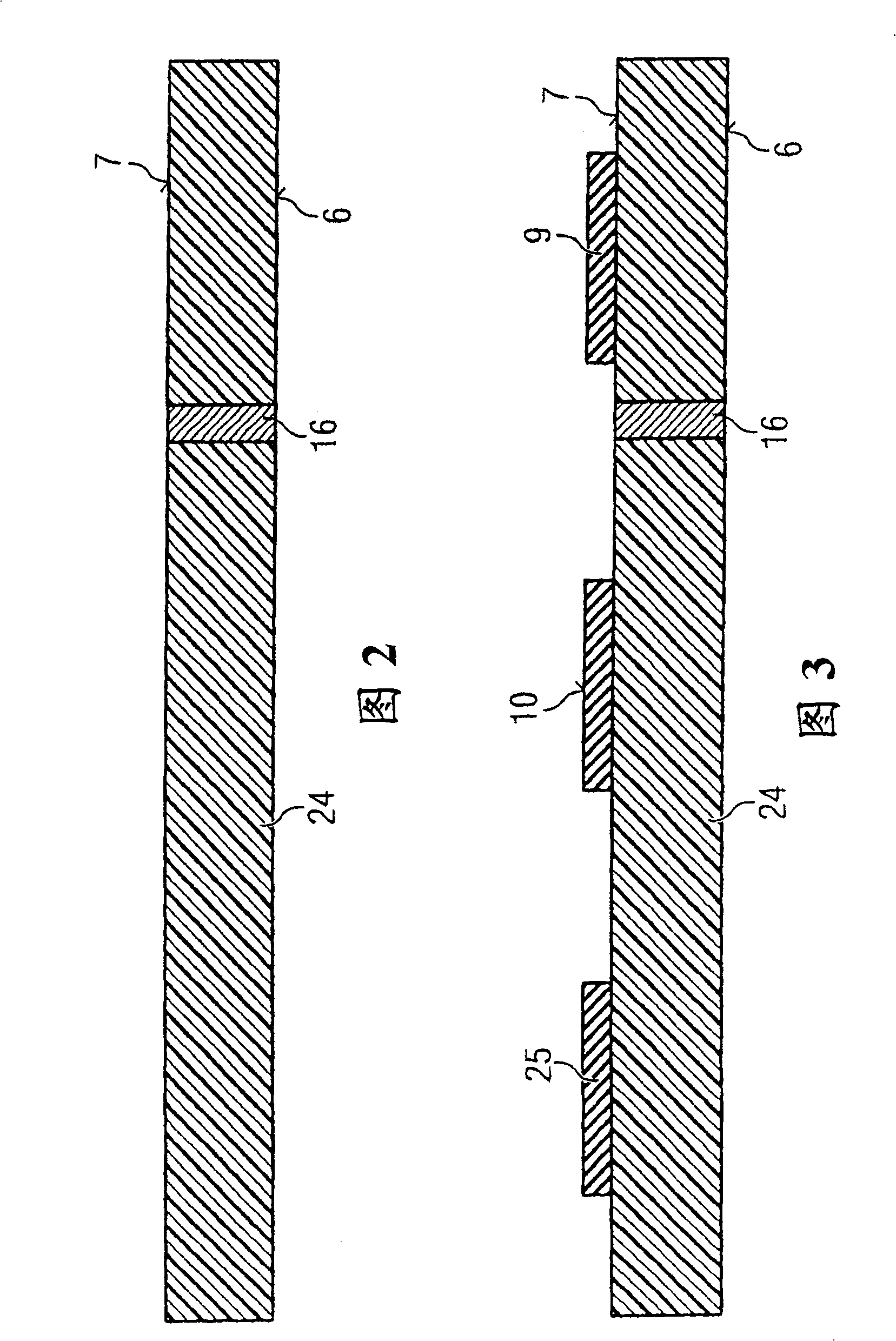

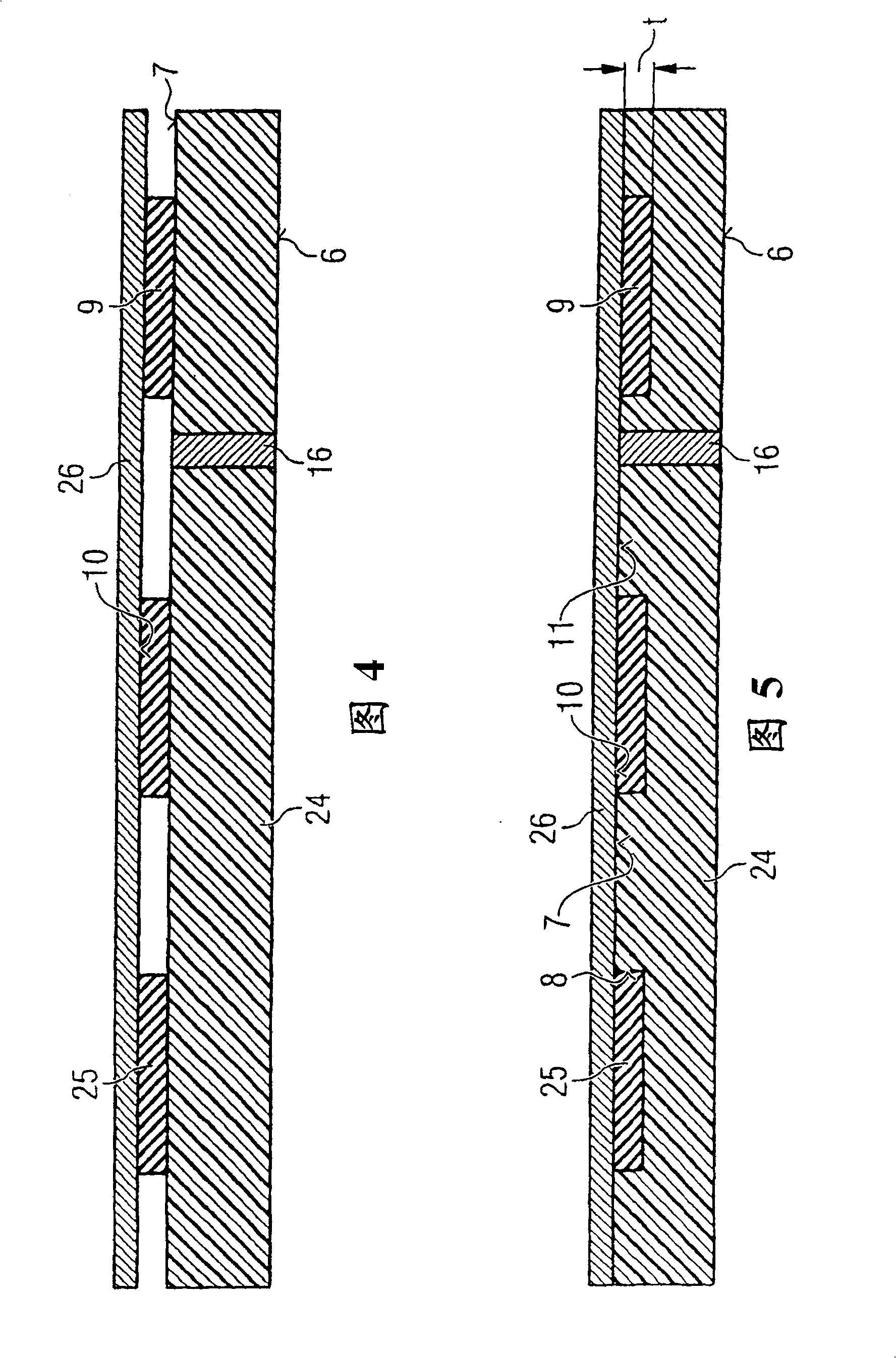

[0051] figure 1 Shown is a schematic cross-sectional view through a part of the wiring substrate 5 . The wiring substrate 5 has a base plate 24 with a top side 7 and a bottom side 6 . From the top side 7 an elastic material 9 is introduced into the substrate 24 , which material forms an elastic material spacer 25 and fills the cutout 8 on the top side 7 of the wiring substrate 5 .

[0052] The spacer 25 of elastomeric material incorporated into the substrate 24 has a top side 10 forming a coplanar area 11 with the top side 7 of the wiring substrate 5 . The metallic external contact pads 3 are arranged on the coplanar area 11 of the wiring substrate 5 in the region of the pad 25 of elastomeric material. The area extent 13 of the outer contact pad 3 is smaller than the area extent 12 of the elastomeric pad 25 .

[0053] Because the elastomeric pad 25 is compliant, shear loads due to thermal stress or vibration loads acting on the external contact pad 3 can be reduced or dampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com