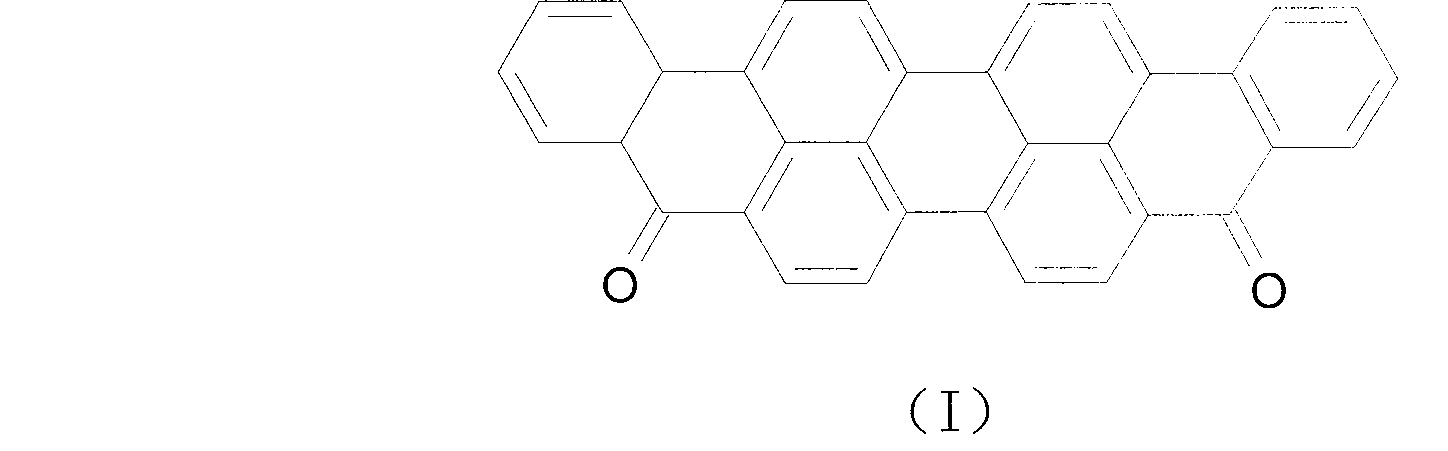

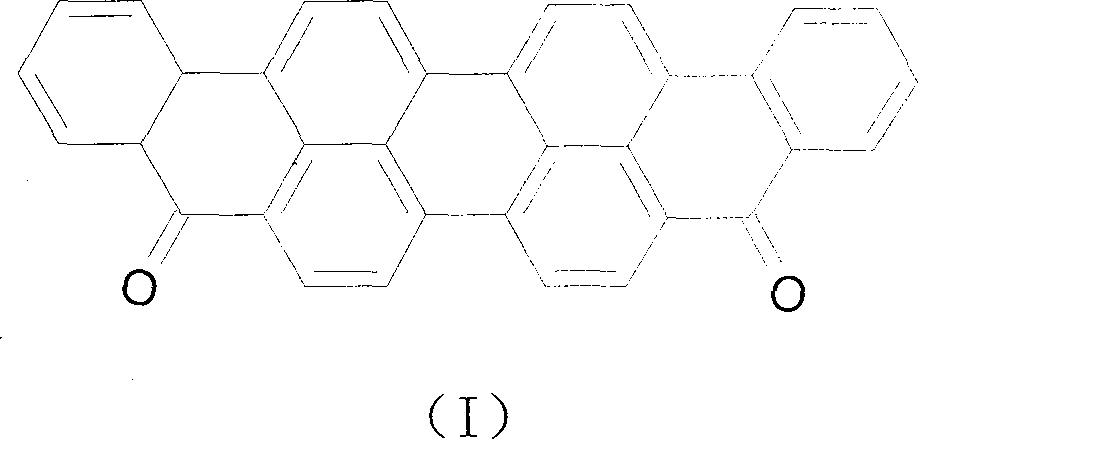

Production technology improvement for reduction cyanine blue BO(C.I. Vat Blue 20)

A technology of compound and structural formula, which is applied in the field of improving the production process of vat blue BO, can solve the problems of difficult processing, high cost, low product strength, etc., and achieve the effect of smooth and thorough reaction and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Check production equipment, instruments, etc.

[0016] 2. Wash and dry the condensation kettle, and close the bottom valve tightly.

[0017] 3. Add 200L of triethylene glycol from the metering tank, start stirring, put 18kg of anhydrous sodium acetate and 260Kg of potassium hydroxide into a 1000L condensation pot in turn under stirring conditions, and heat to 110-125°C with a vapor pressure of less than 0.3Mpa to liquefy the alkali 1 hour to allow the base to fully dissolve.

[0018] 4. When the temperature is 120-125°C, use 0.01-0.02Mpa nitrogen for protection, slowly and alternately add benzophenone and sodium chlorate in a small amount, and cool down with cooling water to keep the temperature below 140°C. The whole process takes 4-5 Hours. After adding the material, turn off the cooling water and let it heat up to the highest point naturally.

[0019] 5. After the temperature is stable, use 0.45-0.6Mpa steam to raise it to 150-155°C and keep it at this temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com