Gas diffusion layer for fuel cell and its production

A gas diffusion layer and fuel cell technology, which is applied to fuel cells, fuel cell parts, electrical components, etc., can solve problems such as narrow selection surface, and achieve the effect of improving electrode performance, simplifying production process, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of composite powder:

[0029] Take 3.0g of acetylene black, wet it with 6mL of isopropanol solution, add 90mL of deionized water, stir mechanically for 15min, and then perform ultrasonic treatment for 30min. Then, under mechanical stirring, slowly dropwise add 30g of 10wt.% PTFE emulsion, and stir well, so that the carbon black and PTFE are evenly mixed. Then place it in a 90°C water bath for coagulation, remove the clear liquid, and dry to prepare a PTFE / C composite precursor with a PTFE content of 50wt.%. Put this precursor into a microwave oven (700W, 2450MHz), and perform a heating procedure of microwave heating for 5s and stopping for 20s to remove residual water in the sample. Subsequently, the heating procedure of heating for 10s and stopping for 60s was repeated until the PTFE content was 30wt%. The obtained PTFE / AB composite powder with PTFE content of 30wt% is denoted as 30PTFE / AB.

[0030] Preparation of the gas diffusion layer:

[0031] Take ...

Embodiment 2

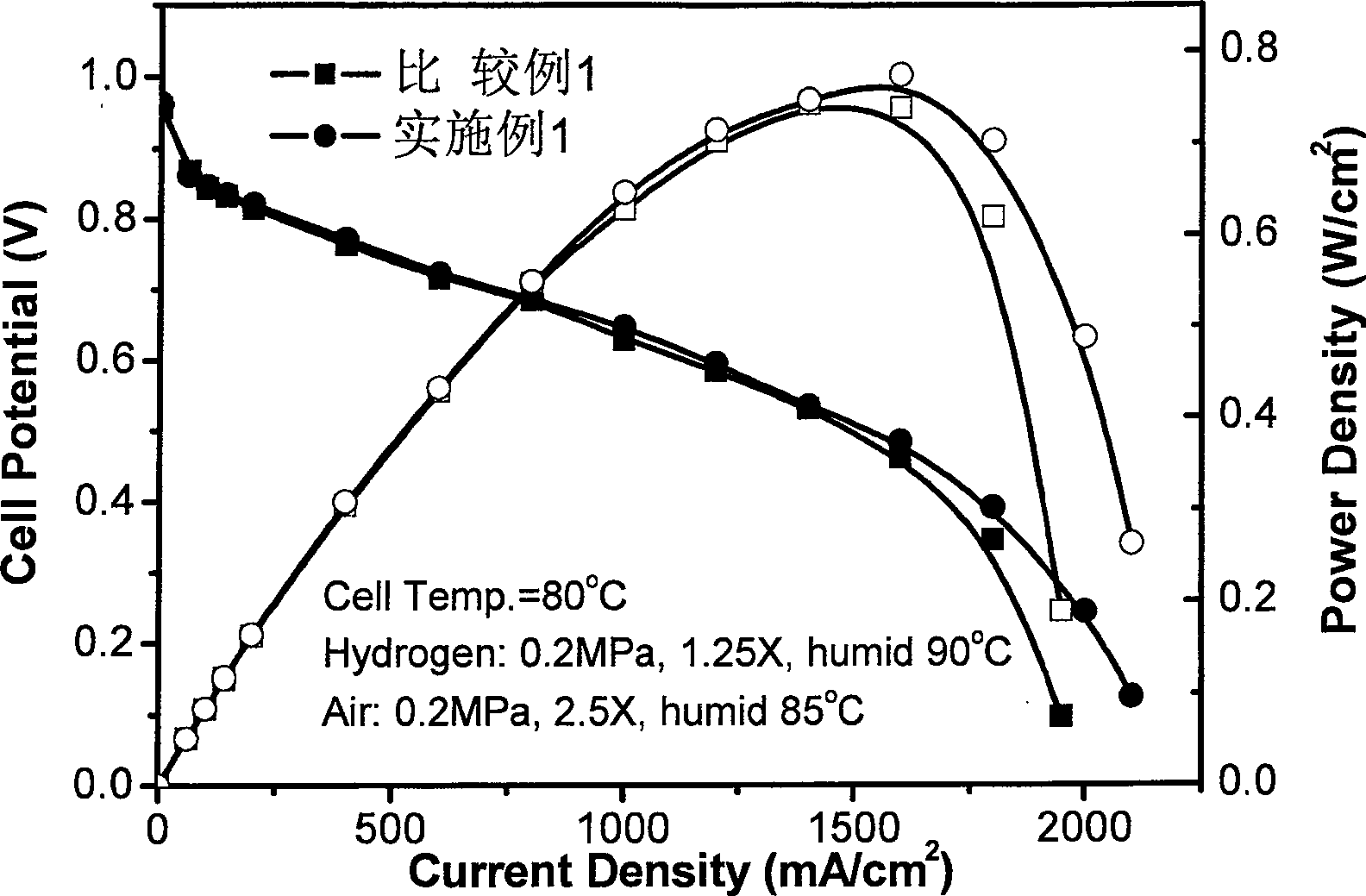

[0034] The 30PTFE / AB composite powder and the gas diffusion layer were prepared according to Example 1, except that the gas diffusion layer after scraping the microporous layer was dried naturally, and the battery could be assembled without roasting. Battery performance curve see Figure 4

Embodiment 3

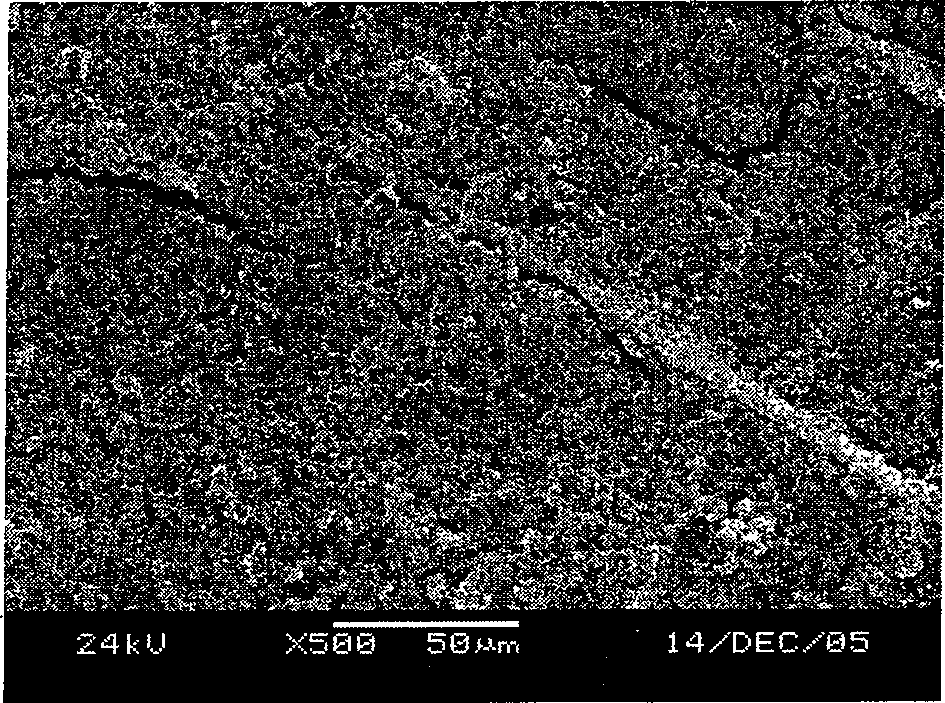

[0036] Take 3.0g VulcanXC-72 conductive carbon black, prepare 30PTFE / VX composite powder according to the method of Example 1. Its SEM photos are from the attached figure 1 visible in .

[0037] Preparation of the gas diffusion layer:

[0038] Take 3.57mg of 30PTFE / VX composite powder, and prepare a microporous layer on one side of the hydrophobic carbon cloth by dry scraping, with a carbon powder load of 0.05mg / cm 2 , the PTFE content of the carbon paper is 60wt.%. Then place it in a roasting furnace, heat at 240°C for 40 minutes, and bake at 340°C for 40 minutes. A single cell was assembled according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com