Nano fiber coating layer super-hydrophobic self-cleaning air filter core and manufacturing method thereof

An air filter and nanofiber technology, which is applied in the field of nanofiber-coated superhydrophobic self-cleaning air filter elements and manufacturing, can solve the problems of porous structure collapse, surface modification process can not be applied, and can not be ventilated, etc., to achieve good Air permeability, efficient self-cleaning and reusable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The nanofiber-coated superhydrophobic self-cleaning air filter element and the manufacturing method of the present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

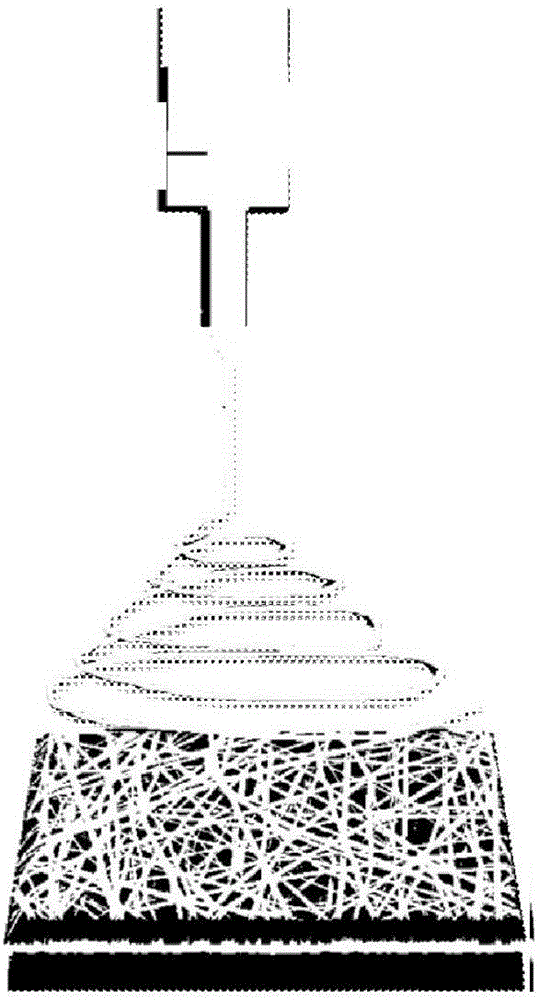

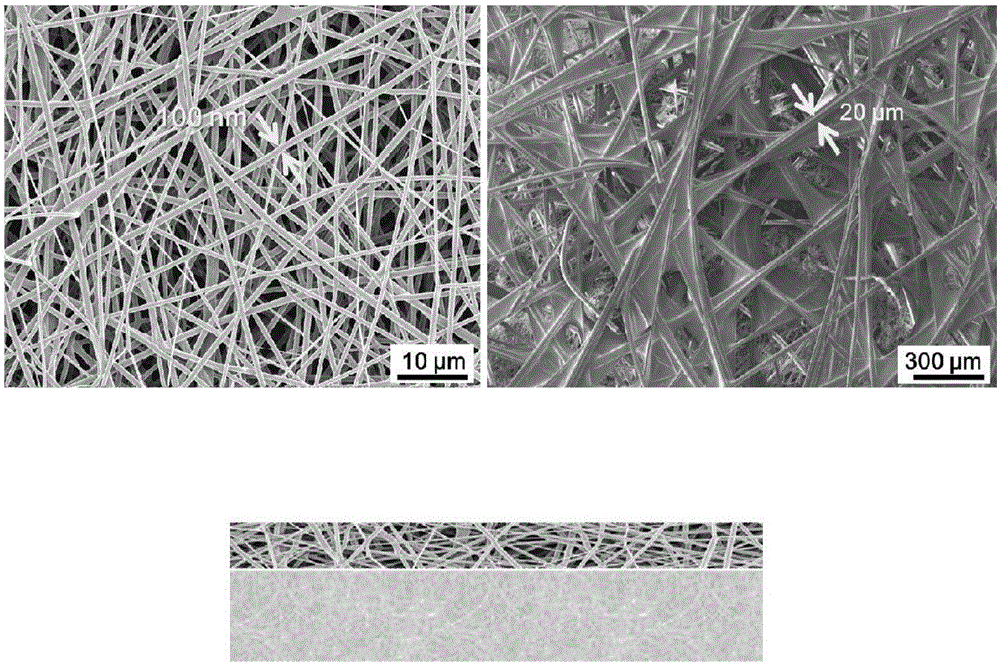

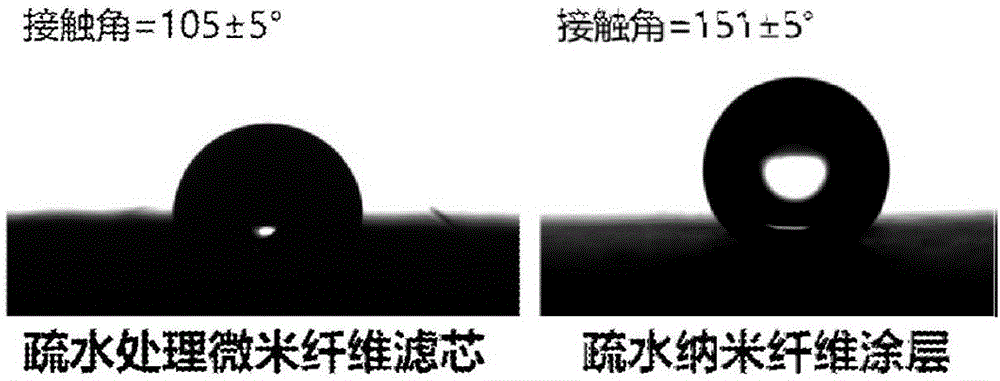

[0025] The invention utilizes the super-hydrophobic low-adhesion surface, imitates the self-cleaning principle of lotus leaves in nature, and uses water flow to clean solid particle pollutants such as dust and other particles attached to the super-hydrophobic surface. In the present invention, two processes of "nano-hydrophobic fiber coating" and "small molecule graft hydrophobic treatment on the surface of the filter element material" are combined to manufacture a strengthened hydrophobic self-cleaning filter element through multi-stage design. Firstly, nano-scale (100- 500nm) hydrophobic polymer fiber coating to construct the super-hydrophobic surface of the nanofiber structure layer; then, use gas fum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com