Production method for barite composite conducting material

A composite conductive and barite technology, used in conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems of affecting the crystal shape integrity, large particle size of composite conductive materials, and low calcination temperature, and improve application performance. , improve the integrity, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

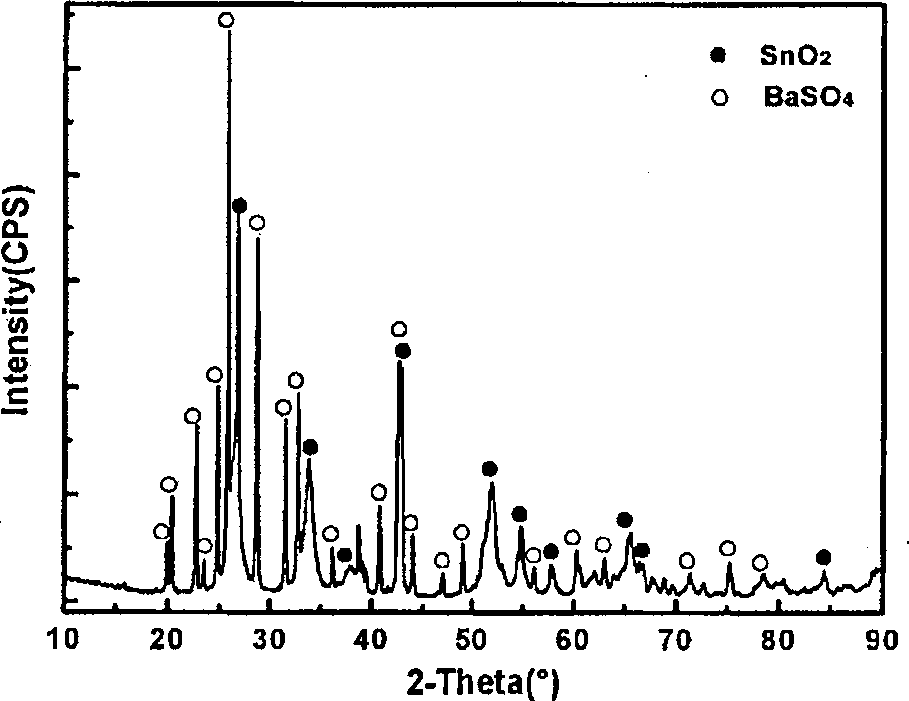

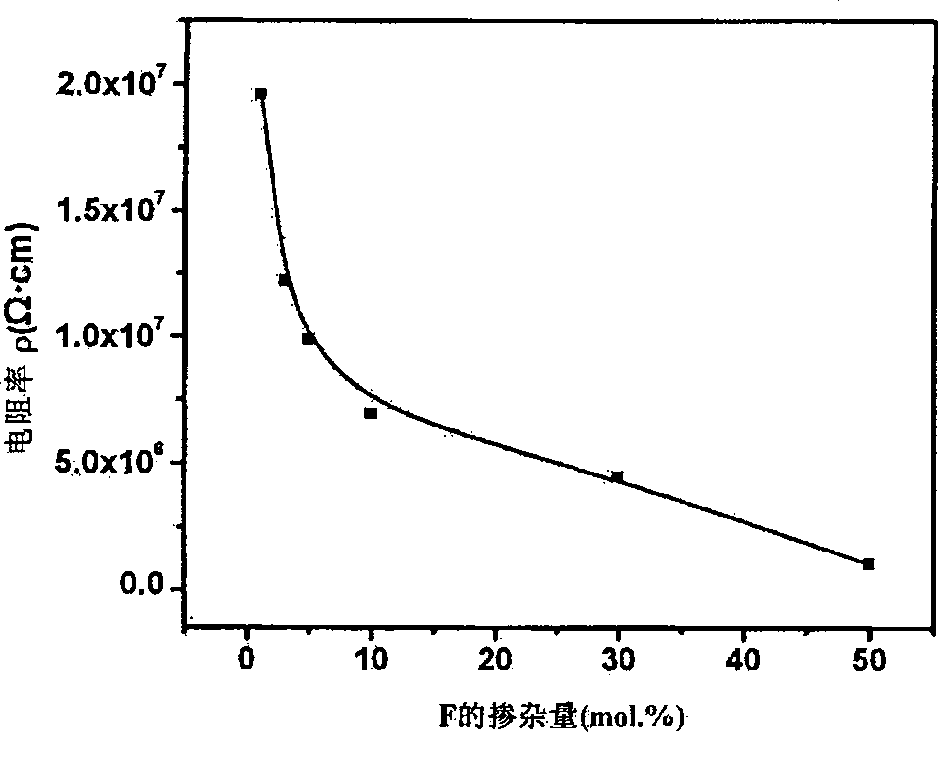

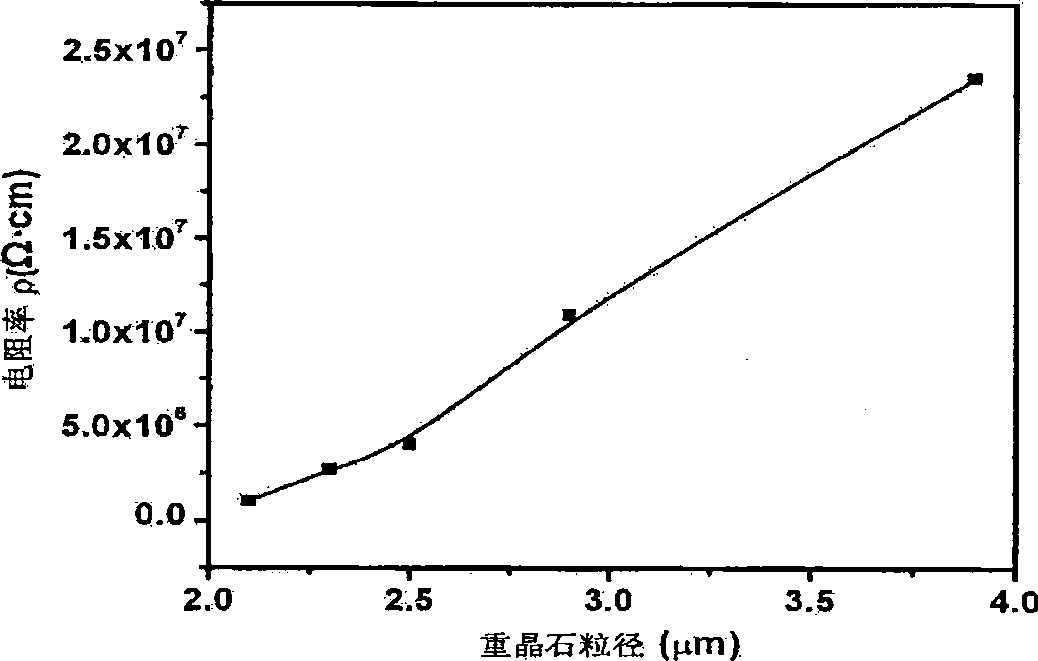

[0017] The original barite is 2kg, ball milled in a stirring ball mill, the ball milling medium is zirconia balls, the weight ratio of balls to materials is 4:1, the ratio of water to materials is 1:1, the ball milling time is 1.5~7.5h, and the obtained particle size is 0.5~ 5.0μm barite powder. After filtering, drying and grinding, it is used for later use. Take 30g of barite powder with a solid content of 30% and place it in 100mL of distilled water, add 0.5% polyethylene glycol as a dispersant, and use SnCl 4 4H 2 O and NH 4 F is raw material, preset SnCl 4 4H 2 O: barite=15:85 (mass ratio), the SnCl of 0.2mol / L 4 4H 2 O ethanol solution with 20% NH 4 The F aqueous solution is mixed, and the F:Sn (substance amount) is 1:99, 3:97, 5:95, 10:90, 30:70 and 50:50, respectively. During constant stirring, the SnCl 4 4H 2 O and NH 4 Add the mixed solution of F dropwise to the distilled water filled with barite, and at the same time add dropwise 40% ammonia solution to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com