Method for preparing modified MCM-41/aluminium oxide composite carrier

A composite carrier and composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of poor structural stability of MCM-41 and achieve the effect of improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

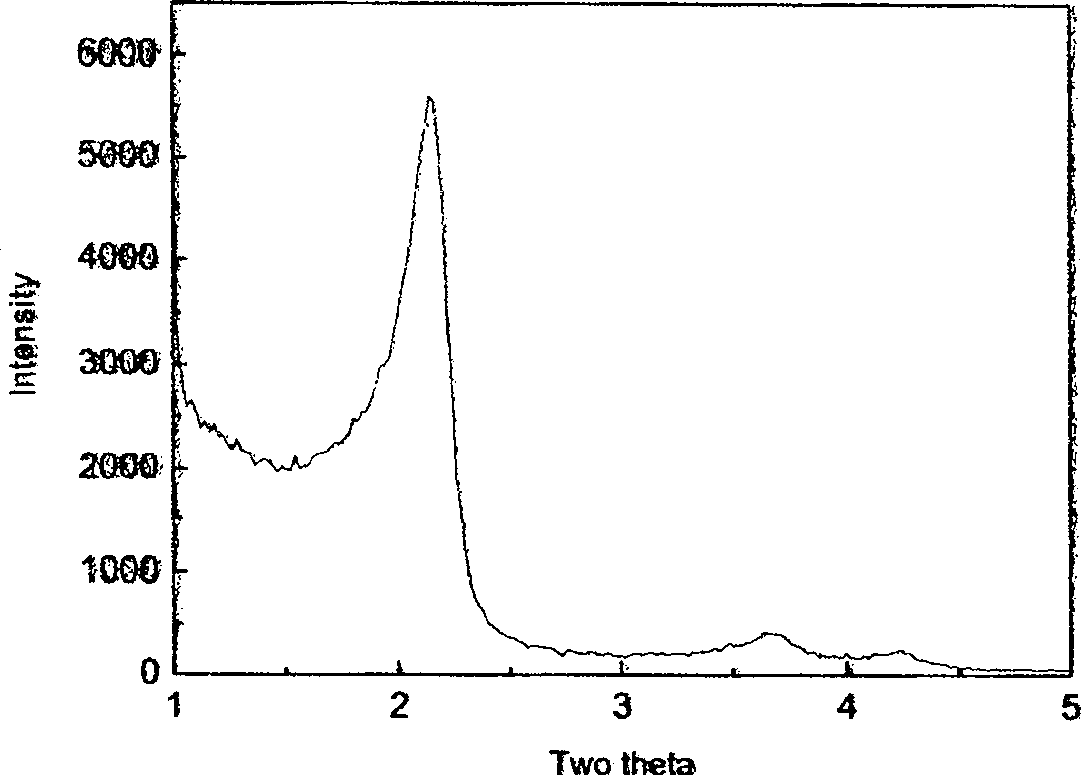

[0037] Dissolve 6.6g of sodium fluoride in 50ml of water, add 24g of γ-Al 2 o 3 , soaked for 24h to obtain F-modified alumina. Then add 352ml water glass (modulus is 3.0, SiO 2 The content is 26m%) in the above F-modified γ-Al 2 o 3 In, soak for 6h. Take 6g of cetyltrimethylammonium bromide and mix it with 100ml of water, stir to form a slurry, mix the two, stir for 1h, and adjust the pH value to 11.0 with 2mol / L dilute sulfuric acid. The composition of the mixture is: 4.5Na 2 O: 8.3SiO 2 :Al 2 o3 :0.67F:0.07CTAB:380H 2 O. Hydrothermal crystallization at 140°C for 24h in an autoclave lined with Teflon, the product was taken out, washed 5 times with 100ml of distilled water, dried at 110°C for 12h, and roasted at 550°C for 5h to obtain white MCM-41 / γ -Al 2 o 3 composite material1. XRD results see figure 1.

Embodiment 2

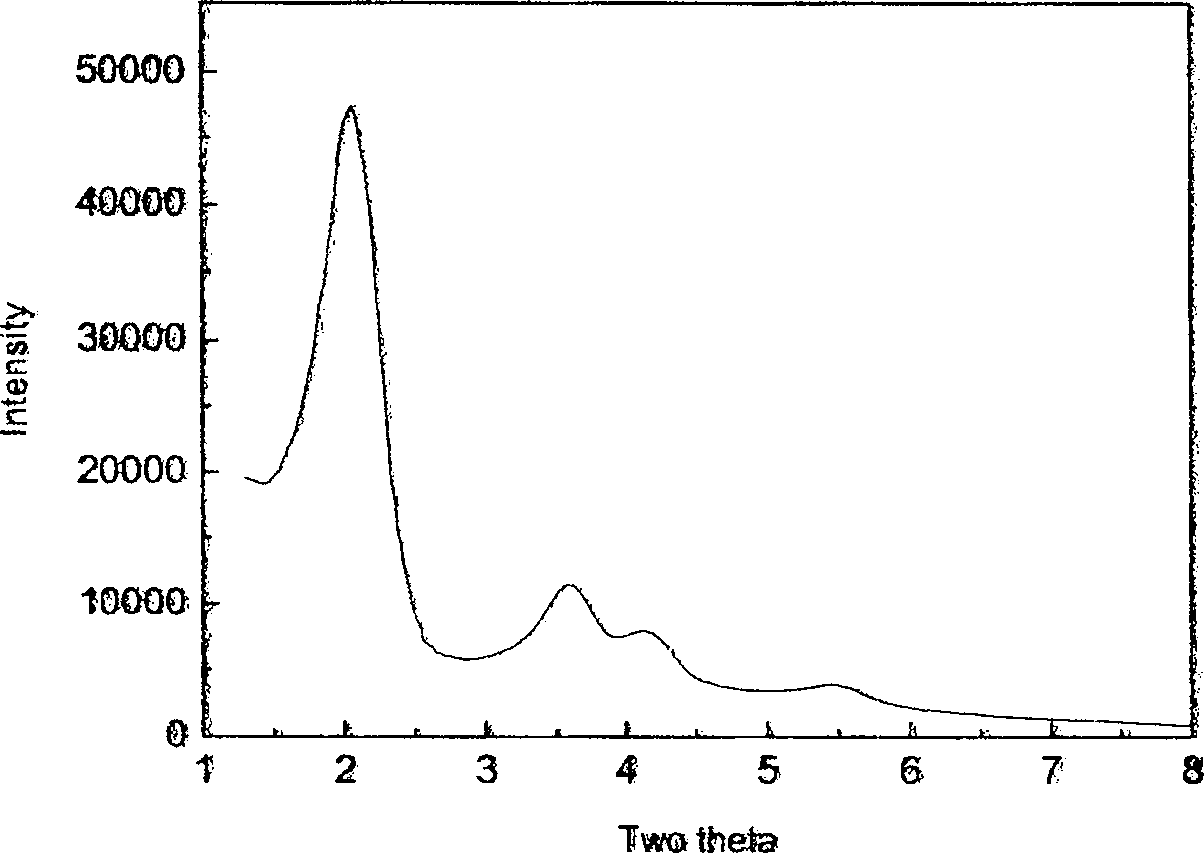

[0039] Dissolve 6.6g of sodium fluoride in 50ml of water, add 24g of γ-Al 2 o 3 , soaked for 24h, get F - Modified alumina. Then add 352ml water glass (modulus is 3.0, SiO 2 The content is 26m%) in the above F-modified γ-Al 2 o 3 In, soak for 6h. Take 6g of cetyltrimethylammonium bromide and mix with 100ml of water, stir to form a slurry, mix the two, after stirring for 1h, adjust the pH value to 12.0 with 2mol / L dilute sulfuric acid, the composition of the mixture is: 4.5Na 2 O: 8.3SiO 2 :Al 2 o 3 :0.67F:0.07CTAB:380H 2 O. Hydrothermal crystallization at 140°C for 48h in an autoclave lined with Teflon, the product was taken out, washed 5 times with 100ml of distilled water, dried at 110°C for 12h, and calcined at 550°C for 5h to obtain white MCM-41 / γ -Al 2 o 3 Composite material 2. XRD results see figure 2.

Embodiment 3

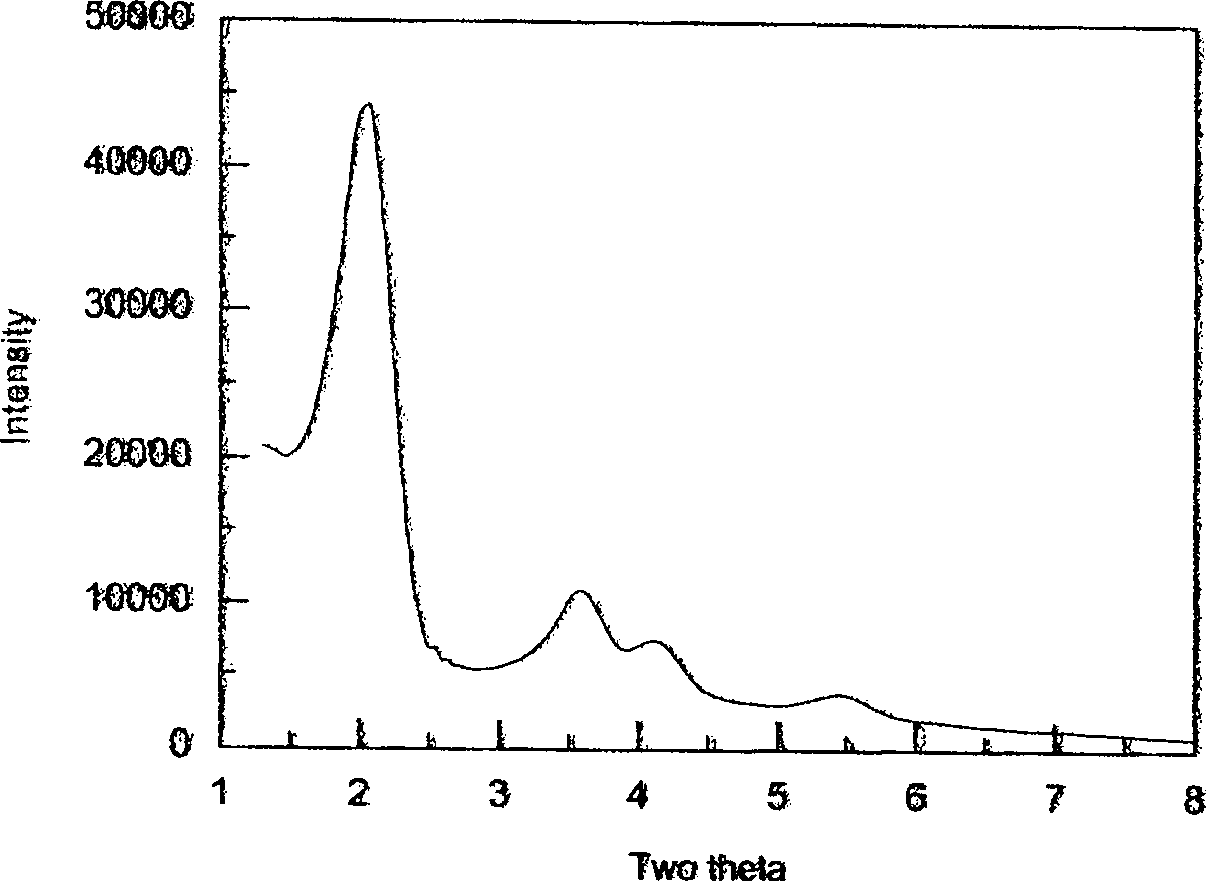

[0041] Dissolve 6.6g of sodium fluoride in 50ml of water, add 24g of γ-Al 2 o 3 , soaked for 24h, get F - Modified alumina. Then add 704ml water glass (modulus is 3.0, SiO 2 The content is 26m%) in the above F-modified γ-Al 2 o 3 In, soak for 6h. Take 6g of cetyltrimethylammonium bromide and mix with 100ml of water, stir to form a slurry, mix the two, after stirring for 1h, adjust the pH value to 12.0 with 2mol / L dilute sulfuric acid, the composition of the mixture is: 4.5Na 2 O: 16.6SiO 2 :Al 2 o 3 :0.67F:0.07CTAB:380H 2 O. Hydrothermal crystallization at 140°C for 24h in an autoclave lined with Teflon, the product was taken out, washed 5 times with 100ml of distilled water, dried at 110°C for 12h, and calcined at 550°C for 5h to obtain white MCM-41 / γ -Al 2 o 3 Composite material 3. XRD results see image 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com