Metal inserting layer in hydride gas phase epitaxial growth gallium nitride film and process for preparing the same

A hydride gas phase and epitaxial growth technology, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of complex process, high cost, metal W insertion layer to reduce defect density, etc. Quality, strong adaptability, effect of reducing dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

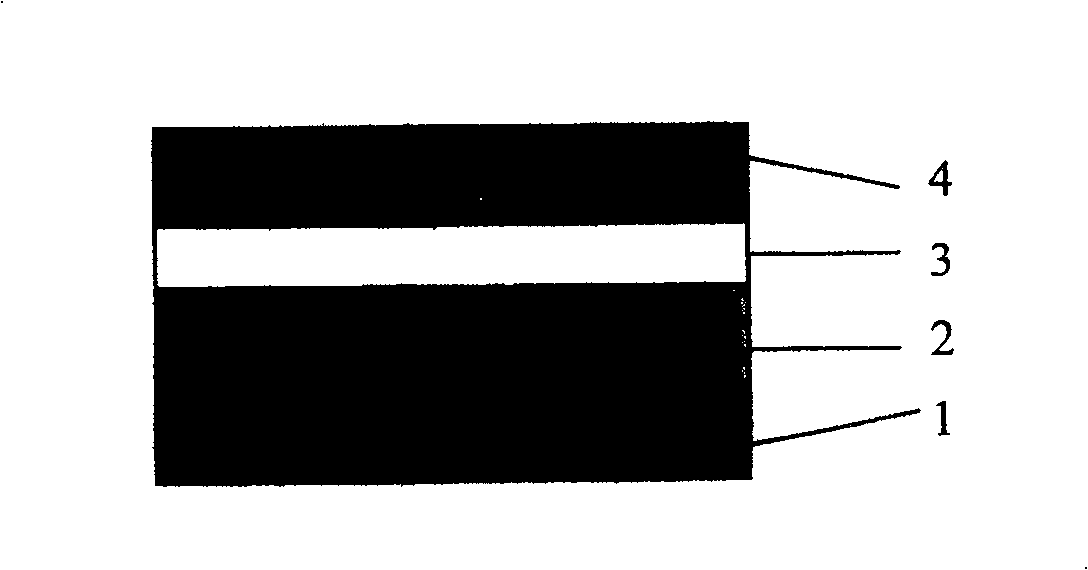

[0016] Using MOCVD method in Al 2 o 3 GaN with a thickness of 200 microns is grown on the substrate as a template, and then an 8nm-thick metal W thin layer is deposited on the template by electron beam evaporation at a temperature of 500 ° C, and then the template with the metal layer is placed into the HVPE reaction chamber, in N 2 The atmosphere is heated to 1100° C., annealed for 20 minutes, and then HVPE GaN growth is performed after annealed. The sample measurement results show that the dislocation density of the GaN film grown by this method is 3 to 4 orders of magnitude lower than that of the GaN film grown directly by HVPE method without intercalation layer, which is about 5×10 6 cm -2 Or so, the crystalline quality is higher.

Embodiment 2

[0018] Using the HVPE method to grow GaN on the SiC substrate as a template, and then deposit a thin layer of metal W with a thickness of 80 nm by electron beam evaporation at a temperature of 550 ° C, and then pass the template with a metal insertion layer through H 2 , annealed at 1150 °C for 15 min thick to continue the GaN growth of HVPE. The measurement results of the sample after growth are as in Example 1.

Embodiment 3

[0020] GaN was grown on the Si substrate by MBE method as a template, and the thickness of gallium nitride as a template was 50 microns, and then a 50nm metal W thin layer was deposited on the template by sputtering, and then deposited on N 2 / H 2 GaN growth of HVPE was performed after annealing at 900°C in a mixed gas with a volume ratio of 90 / 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com