High temperature resisting dipping glue and application thereof

A technology of impregnating glue and high temperature resistance, used in adhesives, surface etching compositions, chemical instruments and methods, etc., can solve the problems of high price of fluorine-containing monomers, limited application scope, etc., and achieve excellent low moisture absorption performance and low curing. Effect of temperature, good thermal oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

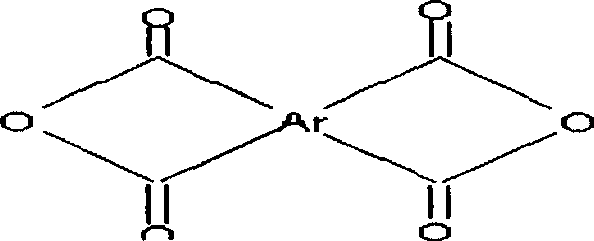

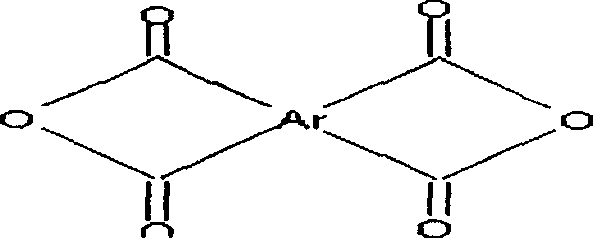

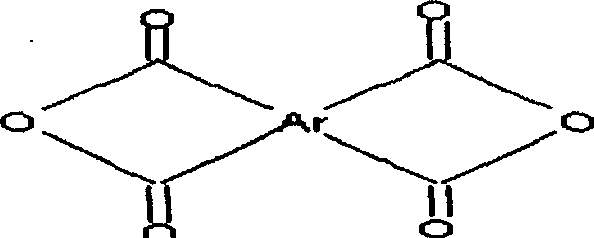

Method used

Image

Examples

Embodiment 1

[0048] Preparation of the first polyimide polymer: 45 parts of 1,4'-bis(4-amino-2-trifluoromethylphenol) benzene was added to 850 parts of N-methylpyrrolidone under inert gas protection and stirring . After the dissolution is complete, add 50 parts of pyromellitic dianhydride in batches at 0-25°C and react for 1-24 hours. A homogeneous viscous liquid was obtained. Add 50 parts of a mixture of acetic anhydride and triethylamine (1:1) into the above liquid under continuous stirring, and react at 0-25°C for 1-24 hours to obtain a transparent solution. Measured at 1720cm by infrared absorption spectrum -1 and 1780cm -1 The characteristic absorption peaks of imine group and carbonyl group appeared, which proved that the corresponding polyimide target product was obtained through the synthesis reaction.

[0049]Preparation of the second polyimide polymer: 50 parts of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 3,3',4,4'-benzophenone tetracarboxylic dianhydride The ...

Embodiment 2

[0053] Preparation of the first polyimide polymer: 50 parts of 4,4'-bis(4-amino-2-trifluoromethylphenol) biphenyl was added with 850 parts of N-methylpyrrolidone under inert gas protection stirring middle. After the dissolution is complete, add 48 parts of 3,3',4,4'-benzophenone tetracarboxylic dianhydride in batches at 0-25°C and react for 1-24 hours to obtain a homogeneous viscous liquid. Add 50 parts of a mixture of acetic anhydride and triethylamine (1:1) into the above liquid under continuous stirring, and react at 0-25°C for 1-24 hours to obtain a transparent solution. The characteristic absorption peaks of imine group and carbonyl group appeared in the infrared absorption spectrum measurement, which proved that the corresponding polyimide target product was obtained through the synthesis reaction.

[0054] Preparation of the second polyimide polymer: add 50 parts of pyromellitic dianhydride to 850 parts of N-methylpyrrolidone under inert gas protection and stirring, af...

Embodiment 3

[0058] Preparation of the first polyimide polymer: 56 parts of 4,4'-bis(3-amino-5-trifluoromethylphenol) biphenyl was added with 850 parts of N-methylpyrrolidone under inert gas protection stirring middle. After the dissolution is complete, add 46 parts of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride in batches at 0-25°C, and react for 1-24 hours. A homogeneous viscous liquid was obtained. Add 50 parts of a mixture of acetic anhydride and triethylamine (1:1) into the above liquid under continuous stirring, and react at 0-25°C for 1-24 hours to obtain a transparent solution. The characteristic absorption peaks of imine group and carbonyl group appeared in the infrared absorption spectrum measurement, which proved that the corresponding polyimide target product was obtained through the synthesis reaction.

[0059] Preparation of the second polyimide polymer: Add 52 parts of bisphenol A dianhydride to 850 parts of N-methylpyrrolidone under inert gas protection and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| flat compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com