Heat treatment wireless virtual meter central controlling system

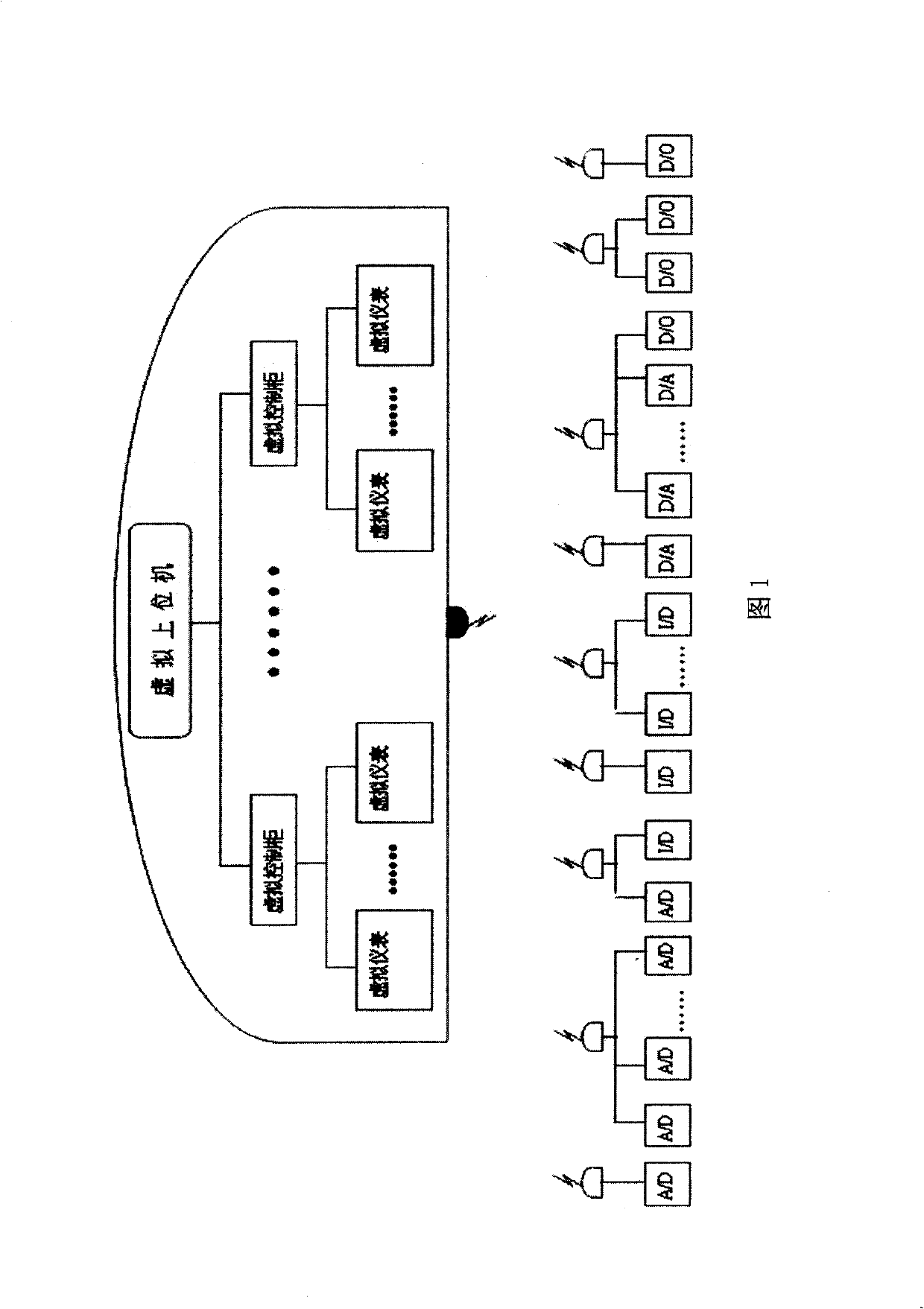

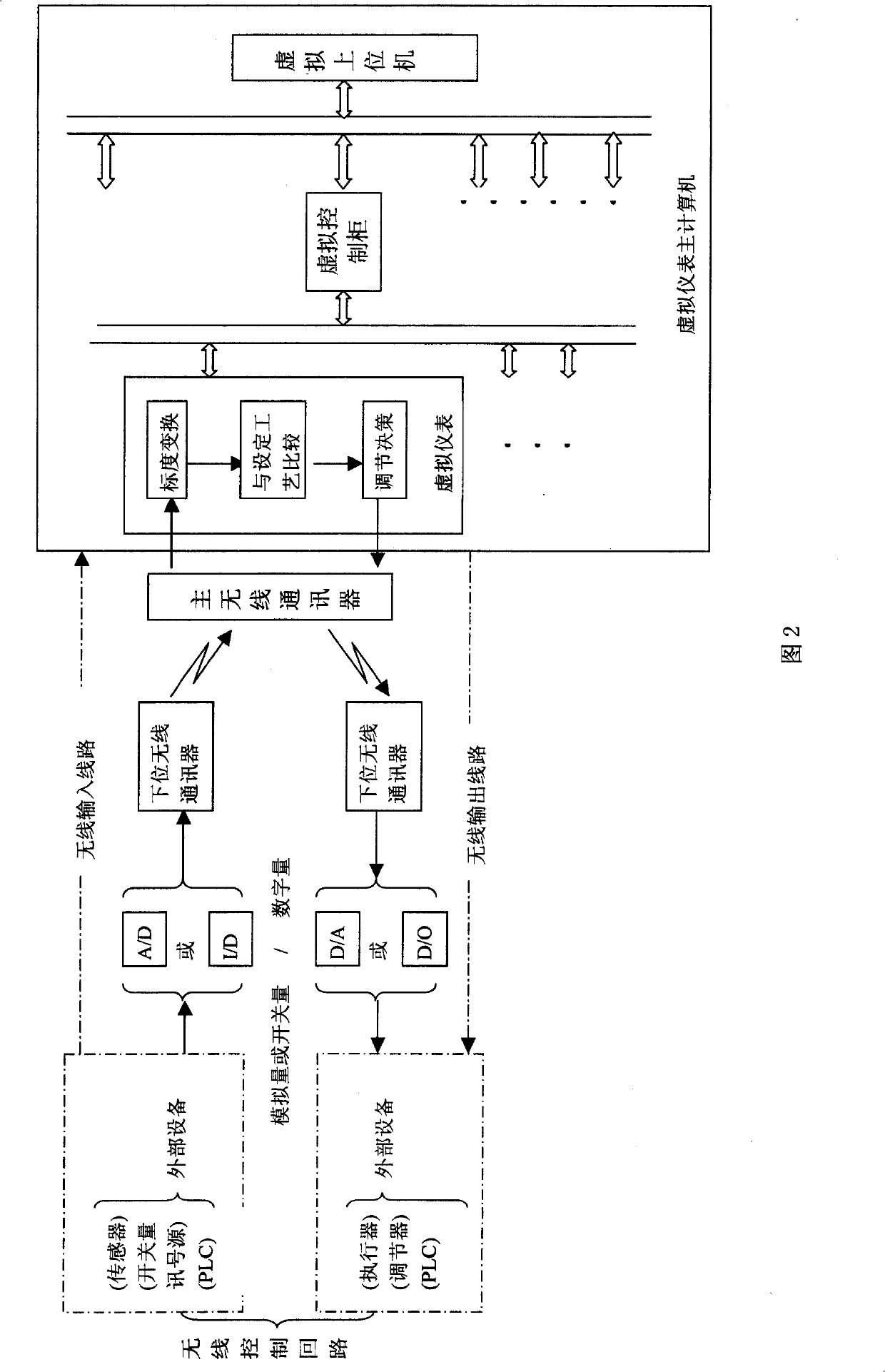

A centralized control system and virtual instrument technology, applied in the system field of heat treatment technology, can solve the problems of hidden dangers of temperature control reliability, lack of ability to judge whether thermocouples are invalid, increase the difficulty and cost of equipment installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

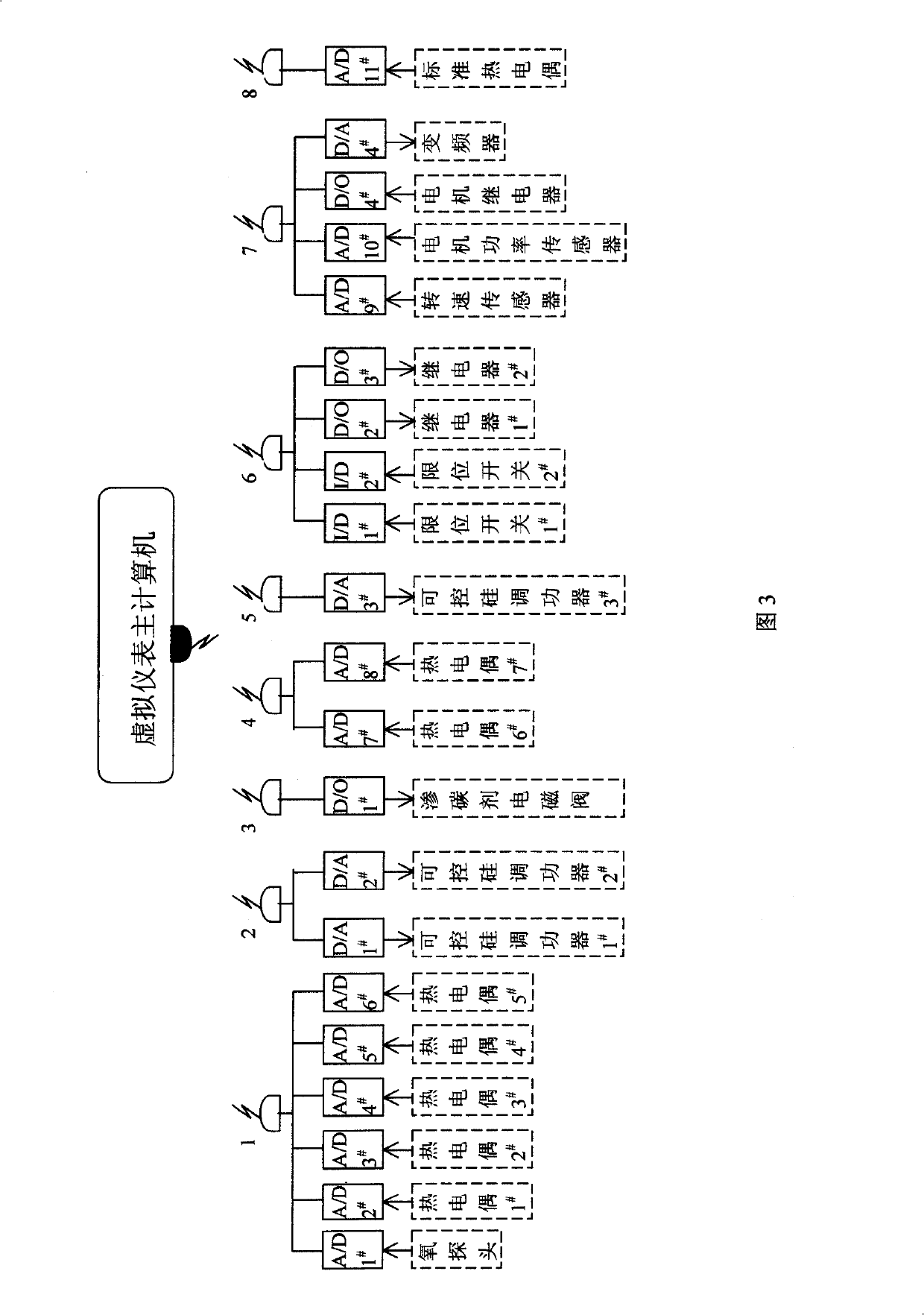

[0119] Embodiment 1: Application of heat treatment wireless virtual instrument control system in automobile gear factory

[0120] The heat treatment workshop of the automobile gear factory has a well-type gas carburizing furnace, a mechanized quenching tank and a tempering furnace. Pit furnace with oxygen probe to measure the inside of the furnace A furnace temperature monitoring thermocouple (1 # thermocouple). Drop in methanol and isopropanol as carburizing agent, and install a solenoid valve on the pipe leading into the carburizing agent. The well type gas carburizing furnace is divided into upper and lower temperature control areas, in which two groups of electric heating elements are respectively composed of 1 # and 2 # The thyristor power regulator adjusts the heating power. 2 # 、3 # Thermocouples are a set of double thermocouples used for temperature measurement in the upper zone. 4 # 、5 # The thermocouple is a set of double thermocouples used for temperature...

Embodiment 2

[0141] Example 2: Centralized Control System of Virtual Instrument for Vacuum Heat Treatment Flexible Production Line

[0142] The function definition of the system:

[0143] The vacuum heat treatment flexible production line is composed of a vacuum furnace moving left and right, a high-pressure gas quenching chamber, and an oil quenching chamber. The vacuum furnace has three working positions. For the station docked with the gas quenching chamber, the vacuum furnace requires temperature control and vacuum degree (pressure) control. The working process is as follows, the workpiece is loaded into the furnace, the furnace door is closed, the vacuum pump is turned on, and the furnace pressure of the vacuum furnace is kept below 1.3Pa. Power on and heat up to make the furnace temperature reach the set heating temperature, generally 930°C-1100°C (depending on different workpieces, set in the process file). Measure the furnace temperature with a thermocouple, and adjust the heatin...

Embodiment 3

[0153] Embodiment 3, wireless virtual instrument centralized control system for heat treatment of sealing multi-purpose furnace production line

[0154] The sealed multi-purpose furnace is composed of a loading and unloading platform feeding trolley, a sealed multi-purpose furnace, a cleaning machine and a tempering furnace, as shown in Figure 7. The feeding trolley can move left and right, and there is a pushing mechanism on the trolley to push the workpiece into each equipment. Or pull the workpiece from each equipment to the feeding car. The sealed multi-purpose furnace is composed of a front room and a working room. The front room has an outer furnace door, and the bottom of the front room is a quenching oil tank. The bearing plane of the working furnace is at the same level, and the lower station of the quenching elevator makes the workpiece immersed in the quenching oil. The quenching oil tank is equipped with an electric stirrer, and there is a middle door between the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com