System for producing ceramic tile with coal gangue and domestic garbage

A technology of domestic waste and coal gangue, which is applied in the field of industrial and domestic waste treatment and utilization systems, can solve problems such as polluting the environment, affecting people's health and plant growth, and achieves the goals of improving quality, saving coal and power resources, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

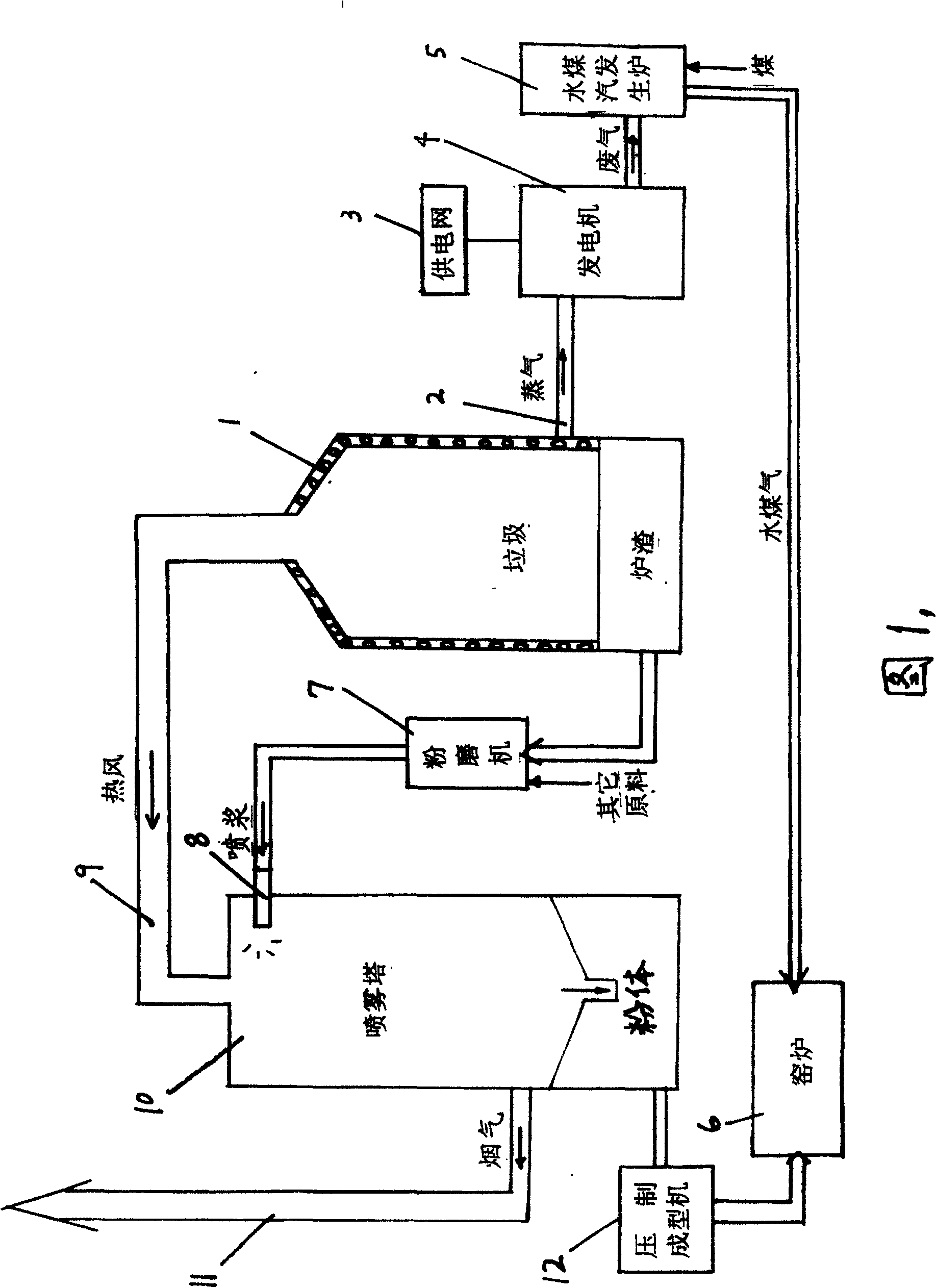

[0016] With reference to the accompanying drawings: design a special circulating fluidized bed combustion boiler 1 that can burn coal gangue and municipal solid waste. Water pipes are arranged around the body of the boiler to heat water to generate steam. A steam pipeline 2 is provided, and a steam generator 4 is connected to the outlet end of the steam pipeline, and the electric output end of the generator is connected with the power supply network 3 in the enterprise to supply the electric energy of the system; the waste gas output end of the steam generator is connected to the The water gas generator 5 is connected to each other. The water gas generator uses steam to react with coal to generate water gas, which is transported to the gas input end of the ceramic body kiln 6 through pipelines. When the water gas burns, the pressed ceramic bricks are fired and molded. There is a furnace bridge in the fluidized bed boiler, under which there is a slag storage room for coal gangue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com