Granular electrode composite material with positive temp coefficient and preparing process thereof

A positive temperature coefficient, composite material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reduced temperature sensitivity, increased conductive contact and manufacturing process complexity, and greater impact on battery rate performance. Temperature safety protection, reducing current, increasing the effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

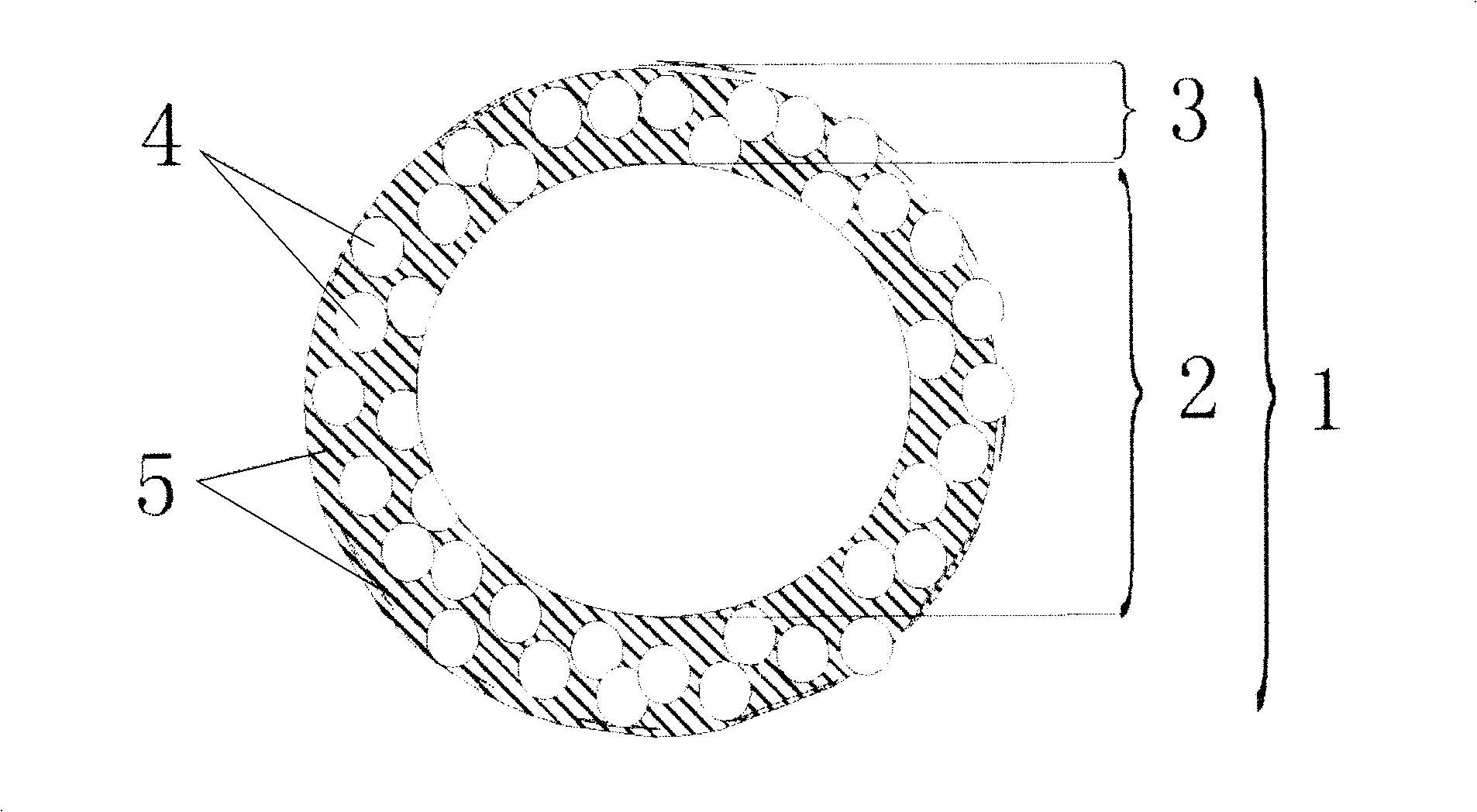

[0025] Thermally dissolve polymer 5 polyethylene (PE) in its good solvent kerosene, mix well and add conductive particles 4: acetylene black, then add active material 2: LiCoO 2 . The particle size of the active material 2 is 6-15 microns, and the shell 3 accounts for 5% of the mass of the electrode composite material; after removing the good solvent, a granular composite electrode material with a positive temperature coefficient is obtained.

Embodiment 2

[0027] Polymer 5: Polyethylene (PE)

[0029] Conductive particle 4: Acetylene black

[0030] Active material 2: LiFePO 4

[0031] The particle size of the active material 2 is: 100-500 nanometers

[0032] The shell 3 accounts for 8% of the mass of the electrode composite material.

Embodiment 3

[0034] Polymer 5: Epoxy Resins and Curing Agents

[0035] Good solvent: ethanol

[0036] Conductive particle 4: Acetylene black

[0037] Active material 2: LiMn 2 o 4

[0038] The particle size of the active material is: 2-10 microns

[0039] The shell accounts for 5% of the mass of the electrode composite material.

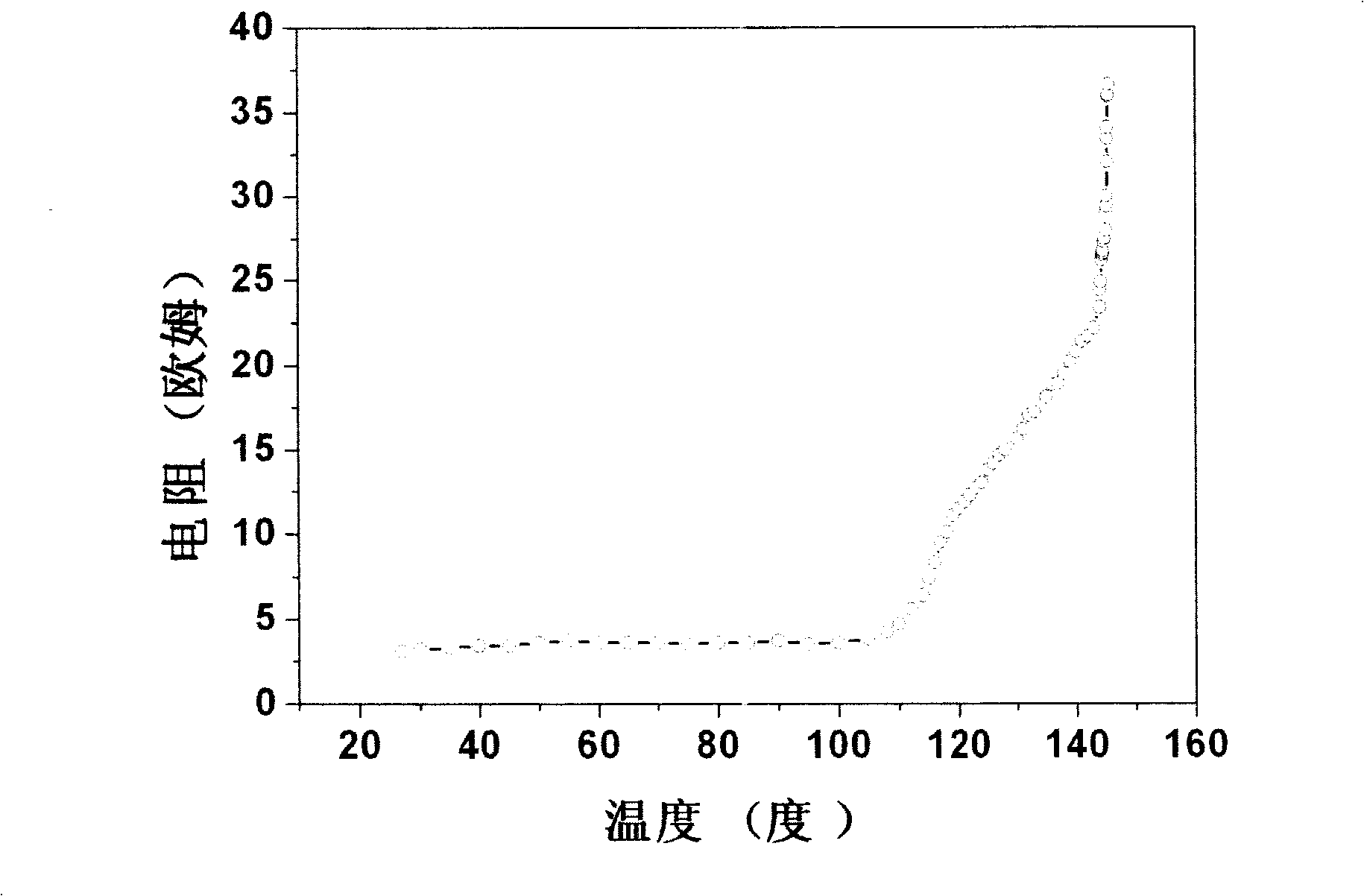

[0040] figure 2 A graph showing the relationship between resistance and temperature of the electrode made of the granular composite electrode material having a temperature coefficient in Example 1 of the present invention is shown. Such as figure 2 As shown, when the temperature is low (room temperature ~ 80 ℃), the resistance of the composite electrode material is low (3 ohms), and when the temperature continues to rise, the resistance also increases. When the temperature reaches 145 ℃, the resistance (40 ohms) is more than ten times larger than the resistance (3 ohms) at room temperature, showing good PTC performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com