Production of hydrogen by catalyzed decomposing magnesium and its mixture doped with other metals

A hydrocarbon, catalytic decomposition technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, non-metallic elements, etc., can solve the problems of difficult removal, deactivation, and short catalyst life. , to achieve the effect of reducing the process of pretreatment, saving cost and time, and selecting a wide range of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

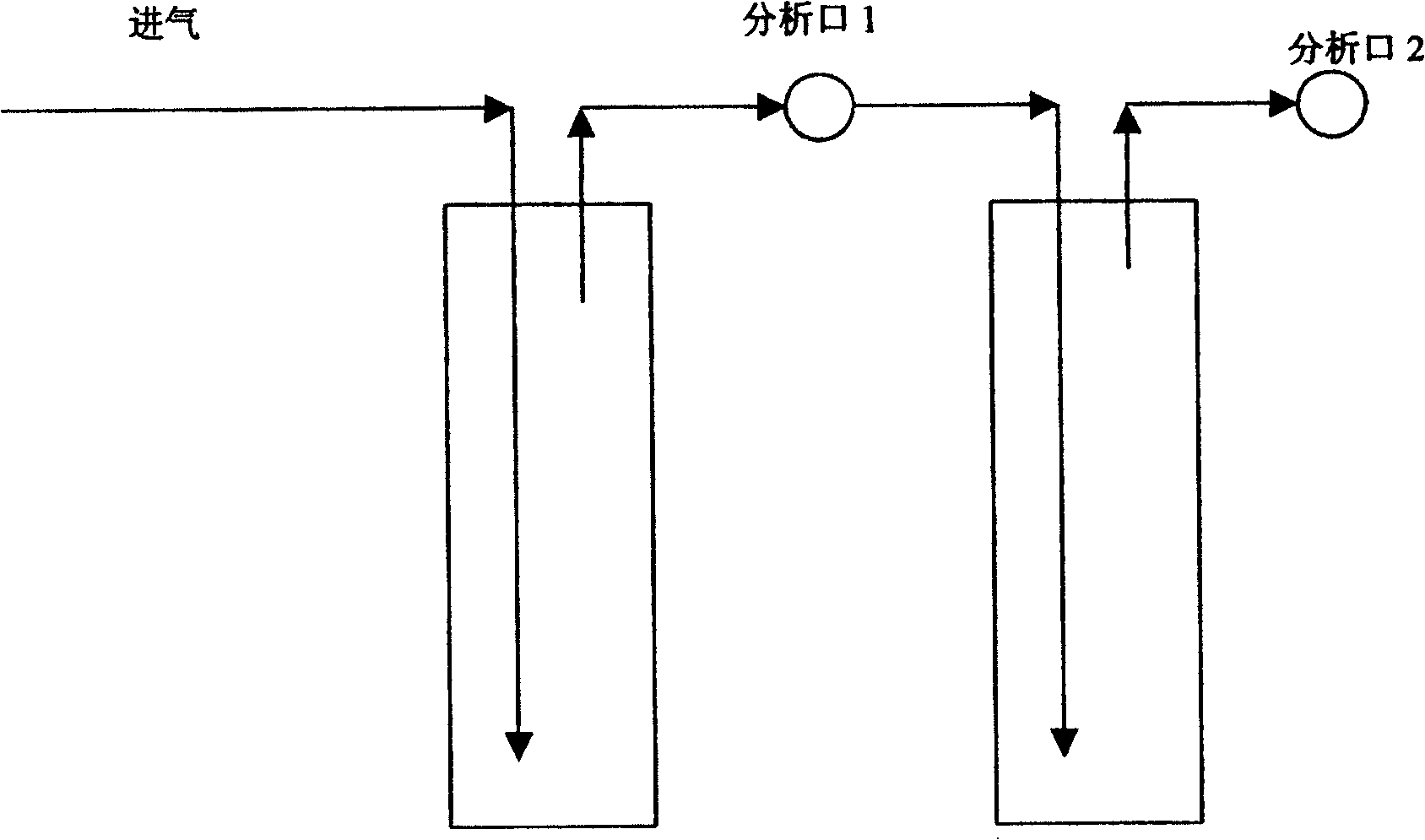

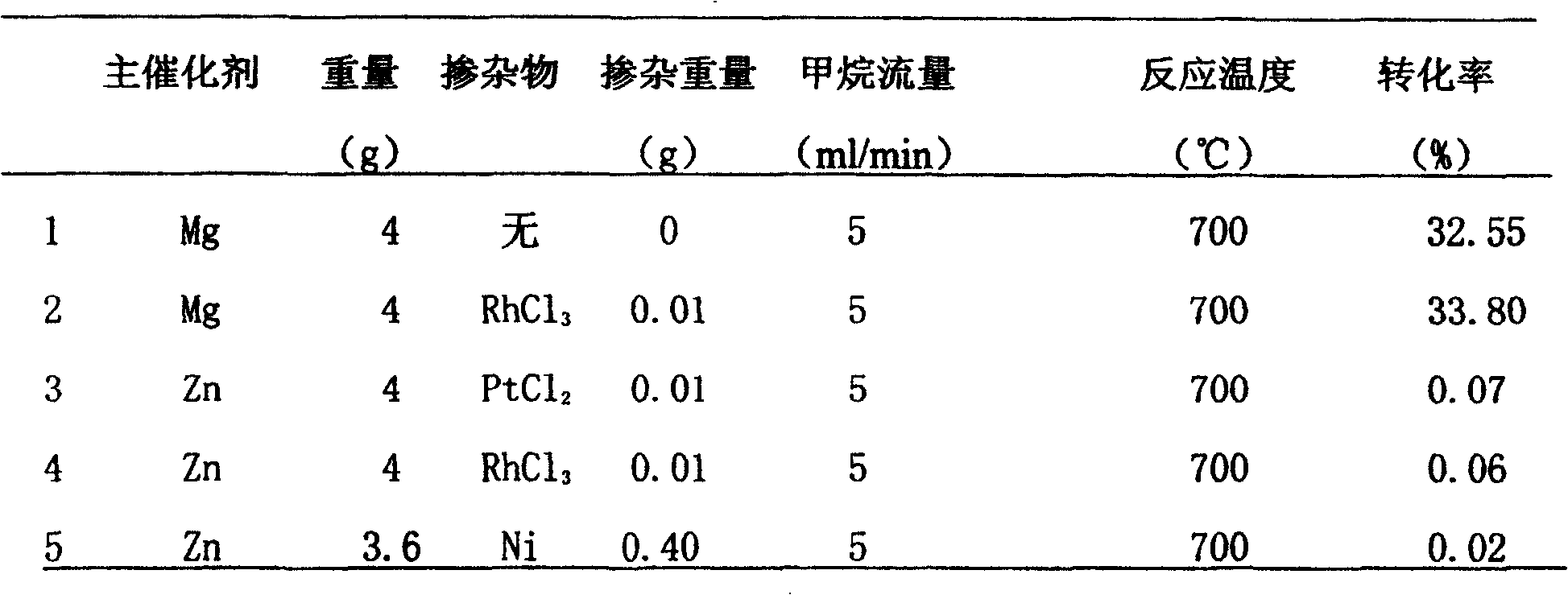

[0014] Embodiment 1~5 Weigh a certain amount of metal catalyst and cocatalyst, pack in the reactor 14 that is furnished with the stainless steel inner tube 15 of one end closure (as figure 1 As shown), the intake pipe 7, the thermocouple 11, and the catalyst are kept in good contact and sealed well. Then the reactor is put into the heating furnace 19, and the height of the reactor is adjusted to ensure uniform heat transfer. Connect the methane cylinder 1 and the reaction pipeline, plug the rubber stopper 9 tightly, and check the device for leaks. Adjust the pressure reducing valve 2 to feed the material so that the air pressure reaches 0.1MPa, open the control valve and use the flow meter 3 and the display device 4 to control the flow rate to 5ml / min. Ventilate for 20 minutes to ensure that other gases in the reactor are flushed out. The heating device includes a temperature controller 5, a thermocouple 11, heating components 12, 13, insulation materials 17, 18, etc. Turn o...

Embodiment 1

[0020]Example 10 Weighed 4 grams of magnesium metal catalyst. The reaction device, operation method, reaction pressure and flow rate were the same as in Example 1, and the reaction temperature was 680° C. After 20 hours of reaction, the analysis results showed that the methane conversion was still stable at 22.0%.

Embodiment 11

[0021] Example 11 Weighed 4 grams of magnesium metal catalyst. The reaction device, operation method and flow rate were the same as in Example 1. The reaction temperature was 700° C. After 20 hours of reaction, the analysis results showed that the methane conversion rate was still stable at 23.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com