Aqueous coating composition

A technology of water-based paint and composition, applied in the direction of coating, latex paint, etc., can solve the problems of easy adhesion of pollutants, decrease of surface gloss, and barriers to painting operation, and achieve excellent paint stability and coating film pollution resistance, The effect of suppressing the increase of paint viscosity and making the painting operation easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

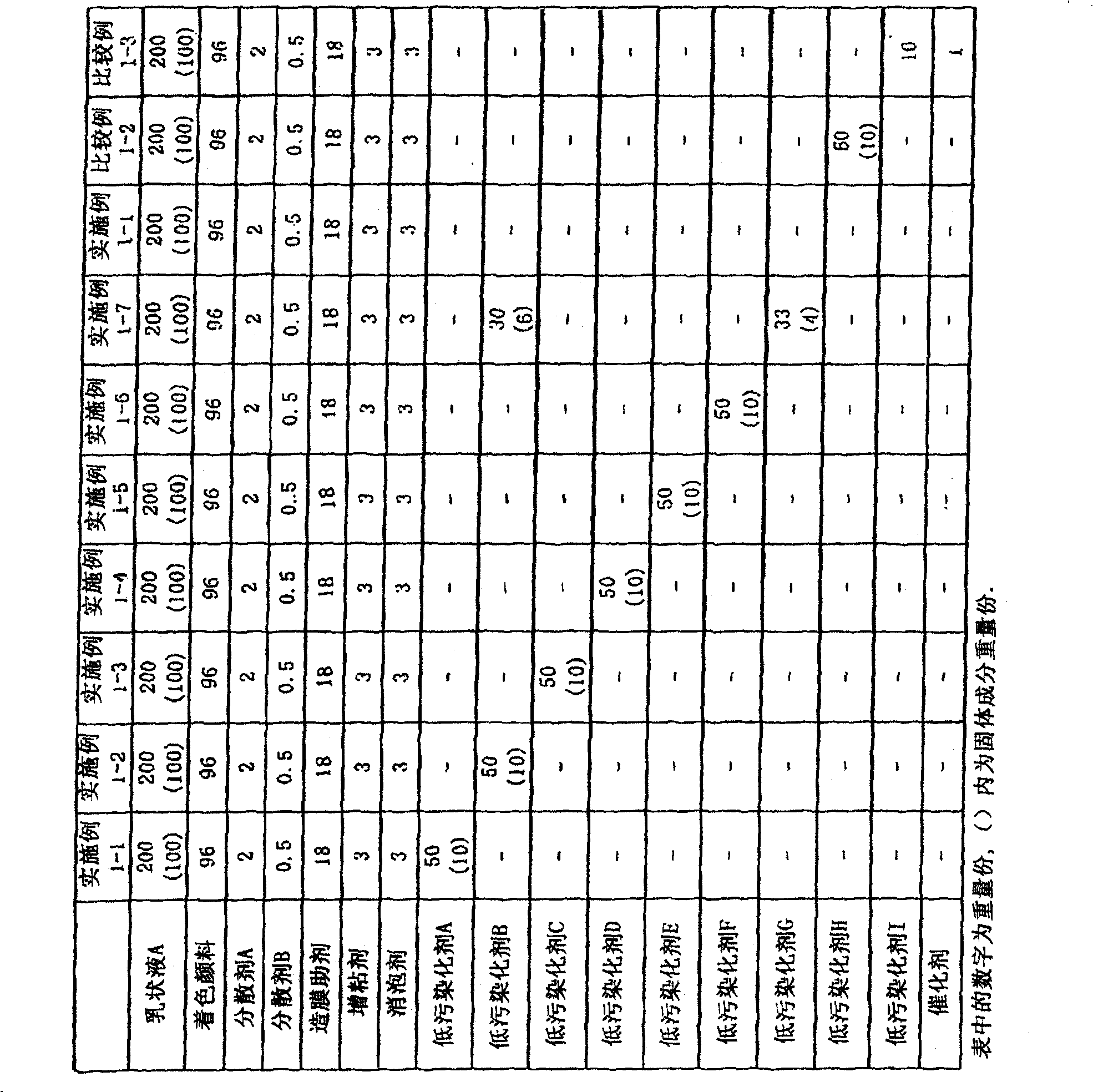

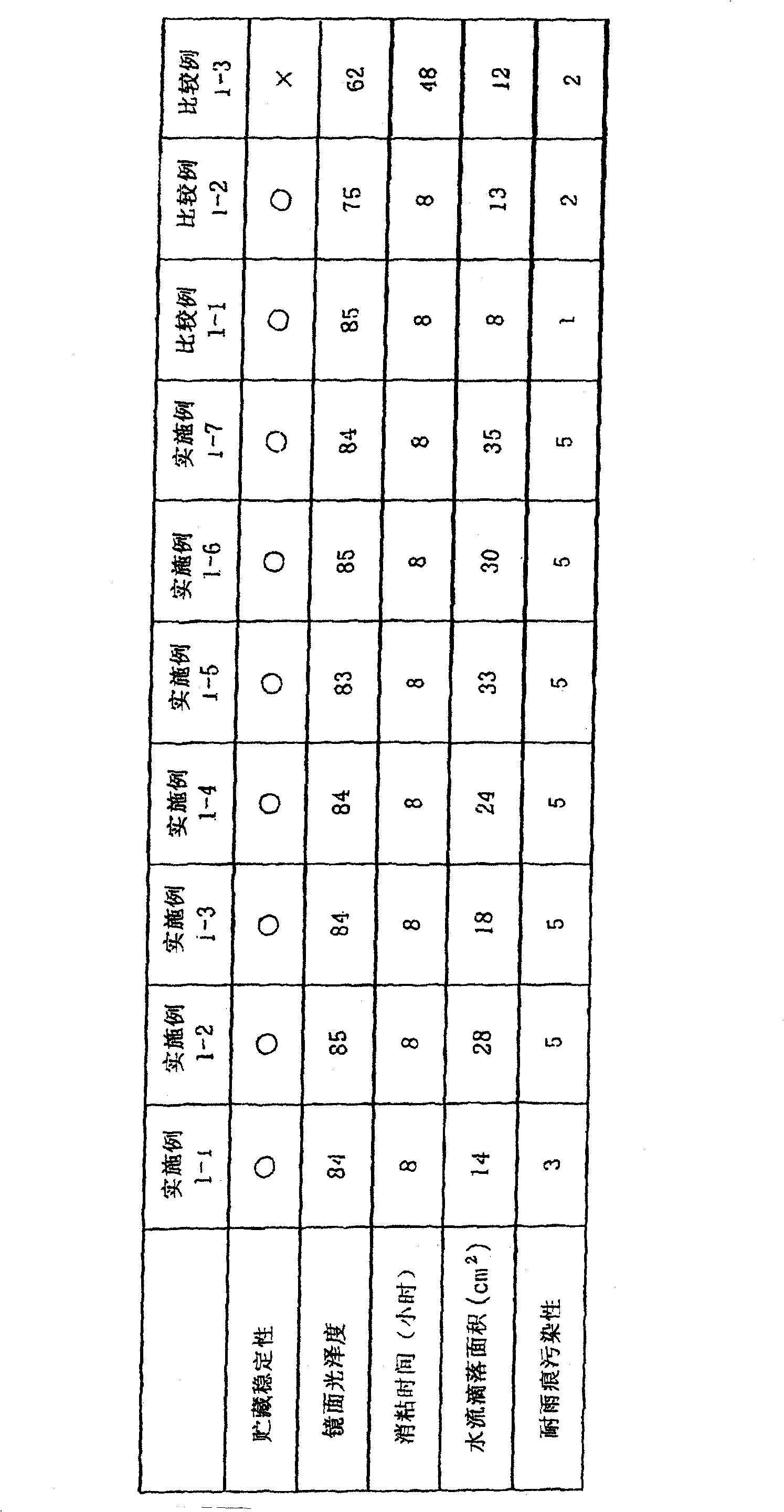

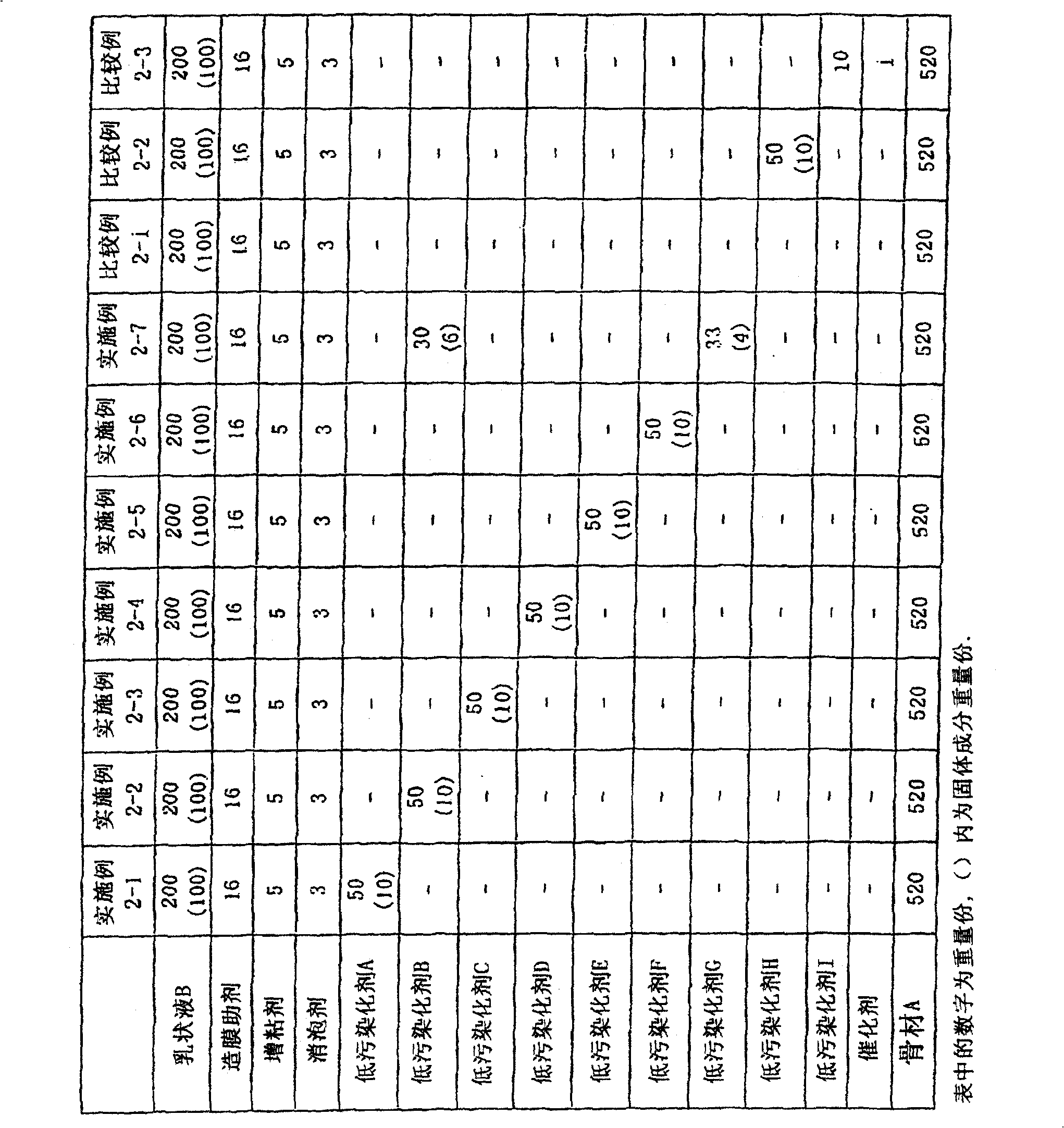

[0133] Examples are given below to clarify the characteristics of the present invention. In Examples, coating materials were produced using each raw material shown below.

[0134] Emulsion A: acrylic resin emulsion (methyl methacrylate-styrene-acrylic acid-2-ethylhexyl-methacrylic acid copolymer, pH 7.5, solid content 50% by weight, minimum film forming temperature 25°C )

[0135] Emulsion B: acrylic resin emulsion (methyl methacrylate-styrene-cyclohexyl methacrylate-(acrylic acid-2-ethylhexyl)-methacrylic acid copolymer, pH is 7.4, solid content is 50% by weight, the minimum film forming temperature is 22°C)

[0136] Emulsion C: Acrylic resin emulsion (styrene-methyl methacrylate-(2-ethylhexyl acrylate) copolymer, minimum film forming temperature 20°C, pH 7.8, solid content 50% by weight)

[0137] ·Water-soluble resin A: Hydroxyethyl cellulose powder

[0138] ・Water-soluble resin B: 3% by weight aqueous solution of galactomannan

Synthetic example 1

[0158] Add 500 parts by weight of low-polluting agent A to a reaction vessel equipped with a reflux condenser and stirring blades, and slowly drop 0.3 parts by weight of trifluoroethanol while stirring. Next, the temperature was raised to 80° C., and the stirring was continued for 24 hours, and then left to cool to room temperature to obtain the decontamination agent B.

Synthetic example 2

[0160] 500 parts by weight of the low-polluting agent A was added to a reaction vessel equipped with a reflux condenser and a stirring blade, and 1.0 parts by weight of tetramethoxysilane was slowly dripped in while stirring. Next, the temperature was raised to 80° C., and stirring was continued for 24 hours, and then left to cool to room temperature to obtain a decontamination agent C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com