Bioactive coating on surface of Titanium or titanium alloy and its preparing method

A bioactive, titanium alloy technology, applied in the direction of coating, etc., can solve the problem of many steps, and achieve the effect of simple operation, improved binding force and cell attachment ability, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] After the Ti-24Nb-4Zr-7.9Sn sample was polished by 100#, 400#, 800# silicon carbide sandpaper, respectively, in acid solution (HNO 3 :HF:H 2 (0=4:1:100) (according to volume ratio), after ultrasonic cleaning for 2 min, rinse with distilled water three times, and dry in air.

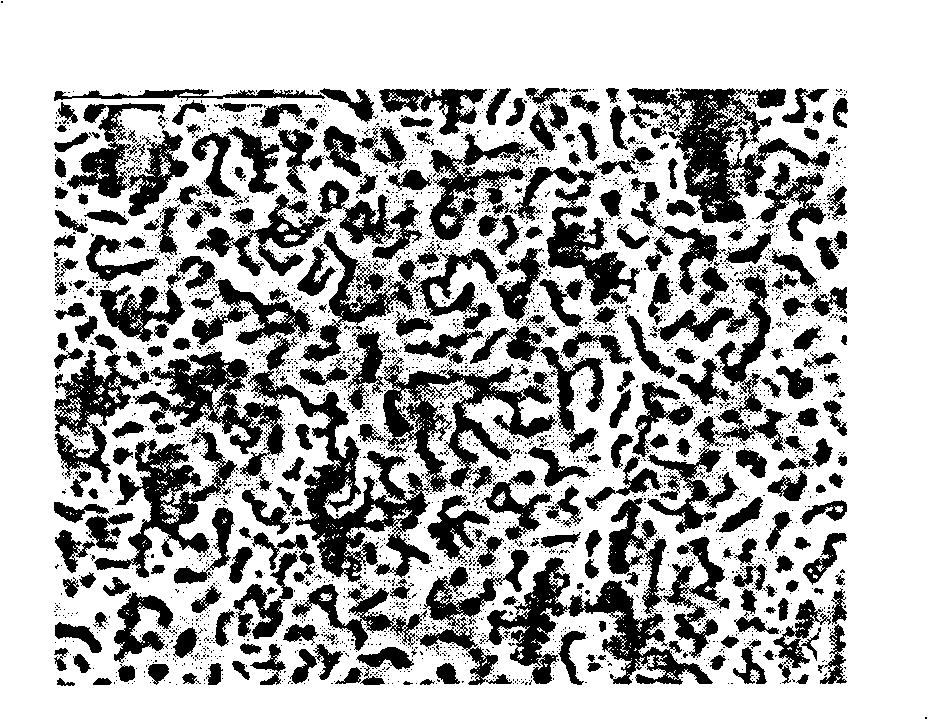

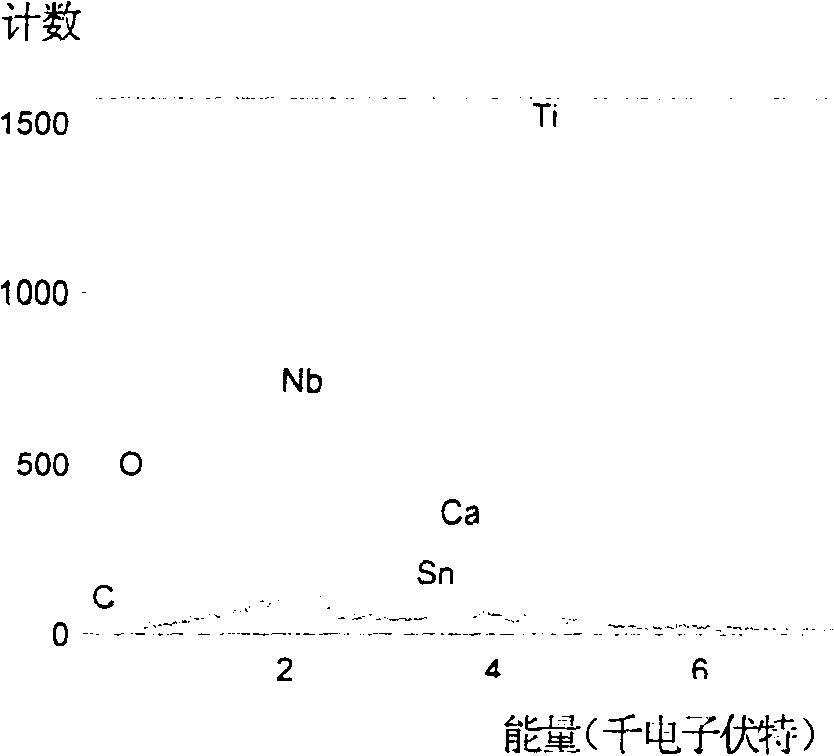

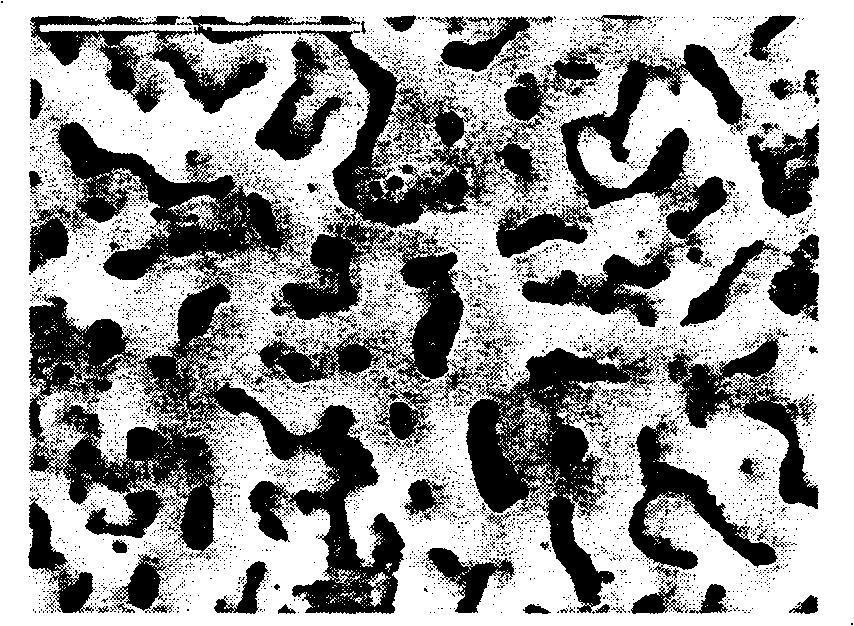

[0045] With stainless steel as the cathode and Ti-24Nb-4Zr-7.9Sn sample as the anode, it is oxidized in calcium acetate solution, the concentration of calcium acetate solution is 0.15M, the pH value of the solution is 8-9, the voltage is 225v, and the working time for 10 minutes, then rinsed with distilled water and dried in air. After the above oxidation treatment, the surface morphology of the Ti-24Nb-4Zr-7.9Sn alloy is porous (see Figures 1 and 2), and the main component is TiO 2 , CaO; X-ray analysis results see image 3 , XPS analysis results are shown in Figure 4.

[0046] Soak the oxidized Ti-24Nb-4Zr-7.9Sn sample in NaOH solution, the concentration of the solution in this example is 3M,...

Embodiment 2

[0053] The difference from Example 1 is:

[0054] Commercially pure Ti samples were polished with 100#, 400#, and 800# silicon carbide sandpaper, respectively, and then washed in acid solution (HNO 3 :HF:H 2 (0=4:1:100) (according to volume ratio), after ultrasonic cleaning for 2 min, rinse with distilled water three times, and dry in air.

[0055] Using stainless steel as the cathode and commercial pure Ti sample as the anode, oxidize in calcium acetate solution, the concentration of calcium acetate solution is 0.1M, the voltage is 225v, the working time is 5min, then rinse with distilled water and dry in the air. After the above oxidation treatment, the surface morphology of the commercially pure Ti sample is porous (see Figure 9 ), and there are CaO particles; the results of energy spectrum analysis are shown in Figure 10 .

[0056] Soak the commercially pure Ti sample after oxidation treatment in NaOH solution, the concentration of the solution in this example is 1M,...

Embodiment 3

[0061] The difference from Example 1 is:

[0062] After the Ti6Al4V alloy samples were polished with 100#, 400#, 800# silicon carbide sandpaper respectively, they were washed in acid solution (HNO 3 :HF:H 2 (0=4:1:100) (according to volume ratio), after ultrasonic cleaning for 2 min, rinse with distilled water three times, and dry in air.

[0063] Using stainless steel as the cathode and Ti6Al4V alloy sample as the anode, oxidize in calcium acetate solution, the concentration of calcium acetate solution is 0.2M, the voltage is 180v, the working time is 5min, then rinse with distilled water and dry in the air. After the above oxidation treatment, the surface morphology of the Ti6Al4V alloy sample is porous and CaO particles exist.

[0064] Soak the oxidized Ti6Al4V alloy sample in NaOH solution, the concentration of the solution in this example is 5M, keep the temperature at 80° C., and soak for 3 hours. Then rinse with distilled water and dry at 40°C.

[0065] The alkali-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com