Making process and product of heat insulating wall material

A manufacturing method and technology of wall materials, applied in the direction of solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of poor durability, high cost, poor thermal insulation performance, etc., and achieve improved thermal insulation Performance, large porosity, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

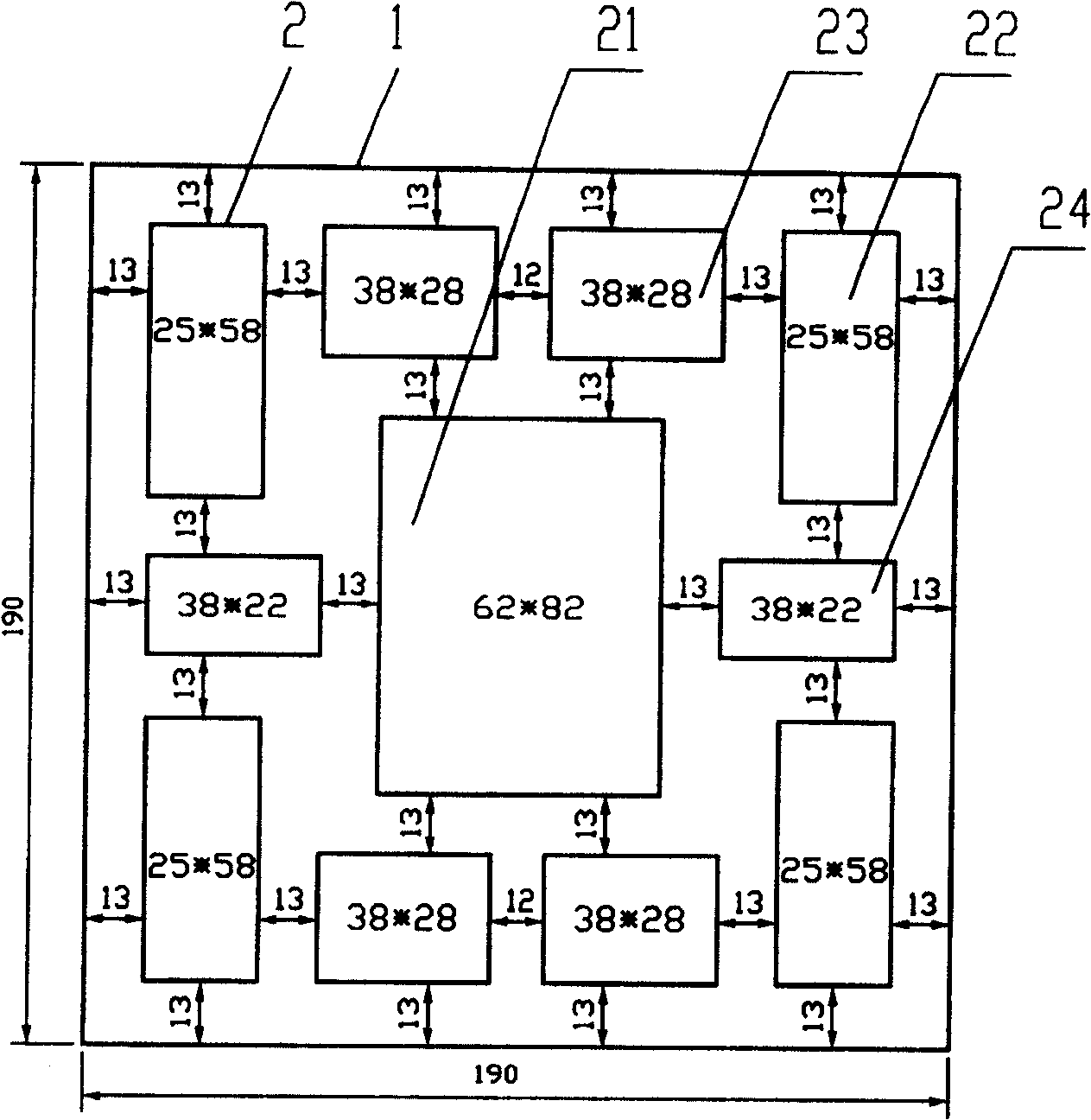

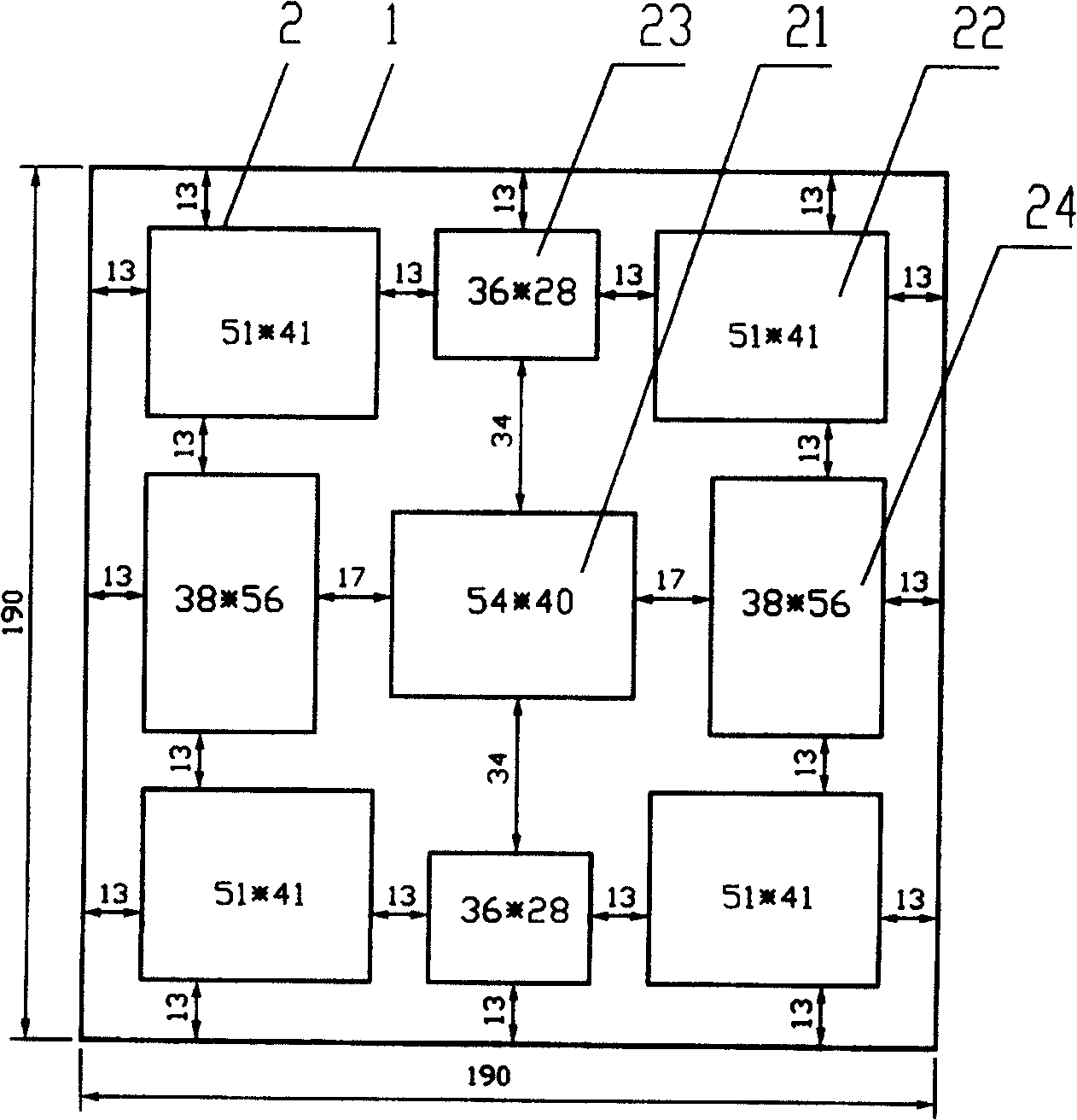

Image

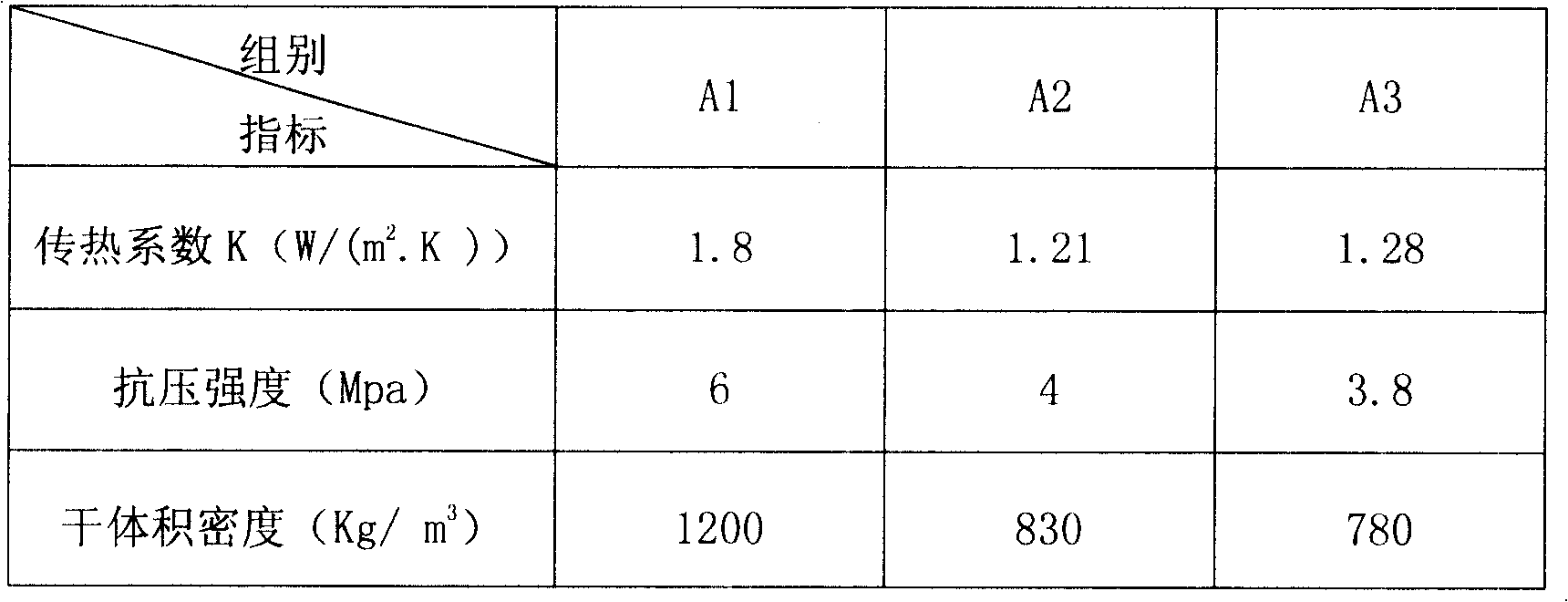

Examples

Embodiment 1

[0042] The manufacturing method of the thermal insulation wall material of the present invention is a processing and molding process in which waste soil, diatomite and admixture are mixed according to a certain proportion and then processed through a technological process.

[0043] 1. The contents of waste soil, diatomite and admixture are as follows (percentage by weight): waste soil is 60%, diatomite is 30%, and admixture is 10%; coal or fly ash in the admixture The weight ratio between sawdust powder, chaff, wheat straw or straw and one or more plant fibers is 1:3.

[0044] ②. The process flow includes:

[0045] A. Raw material preparation: Prepare the above-mentioned required raw materials. Transport waste soil - silt, river mud or mountain mud to the site for stacking, purchase diatomaceous earth and transport it to the site for storage; purchase coal or fly ash and stack it on site; prepare sawdust, chaff, wheat straw or straw etc., store separately.

[0046] The pres...

Embodiment 2

[0061] Embodiment two (the part identical with embodiment one is not described in this embodiment)

[0062] The manufacturing method of the thermal insulation wall material of the present invention is a processing and molding process in which waste soil, diatomite and admixture are mixed according to a certain proportion and then processed through a technological process.

[0063] 1. The contents of waste soil, diatomite and admixture are as follows (percentage by weight): waste soil red 65%, diatomite is 25%, and admixture is 10%; coal or fly ash in admixture The weight ratio between the fiber and the fully combustible non-plastic plant fiber is 1:1.

[0064] ②. The process flow includes:

[0065] A, material preparation: the raw materials of this embodiment are selected as follows: the waste soil is mountain mud—the light sub-clay soil developed in the mountains, and its water content is about 40% in general, and the sand content is less than 10%. Diatomaceous earth is pro...

Embodiment 3

[0075] The manufacturing method of the thermal insulation wall material of the present invention is a processing and molding process in which waste soil, diatomite and admixture are mixed according to a certain proportion and then processed through a technological process.

[0076] 1. The contents of waste soil, diatomite and admixture are as follows (percentage by weight): waste soil is 61%, diatomite is 25%, and admixture is 14%; coal or fly ash in the admixture The weight ratio between the plastic and fully combustible non-plastic plant fibers is 1:6.

[0077] ②. The process flow includes:

[0078] A, raw material preparation: the raw materials of this embodiment are selected as follows: waste soil is the mixture of light sub-clay soil (mountain mud) developed in mountainous areas, building foundation excavation and the silt clay soil of river bed cleaning gained, and its overall water content is 40% Around, the sand content is less than 10%. Diatomaceous earth is produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com