High efficiency plate pipe reverse running type square box heat exchanger

A technology of heat exchangers and return programs, applied in the direction of heat exchangers, indirect heat exchangers, fixed conduit components, etc., can solve the problem of purchasing rubber strips and large labor costs, small flow channel gaps that are easy to block, waste of energy, etc. problems, to achieve the effect of easy maintenance and cleaning, saving land area and saving construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

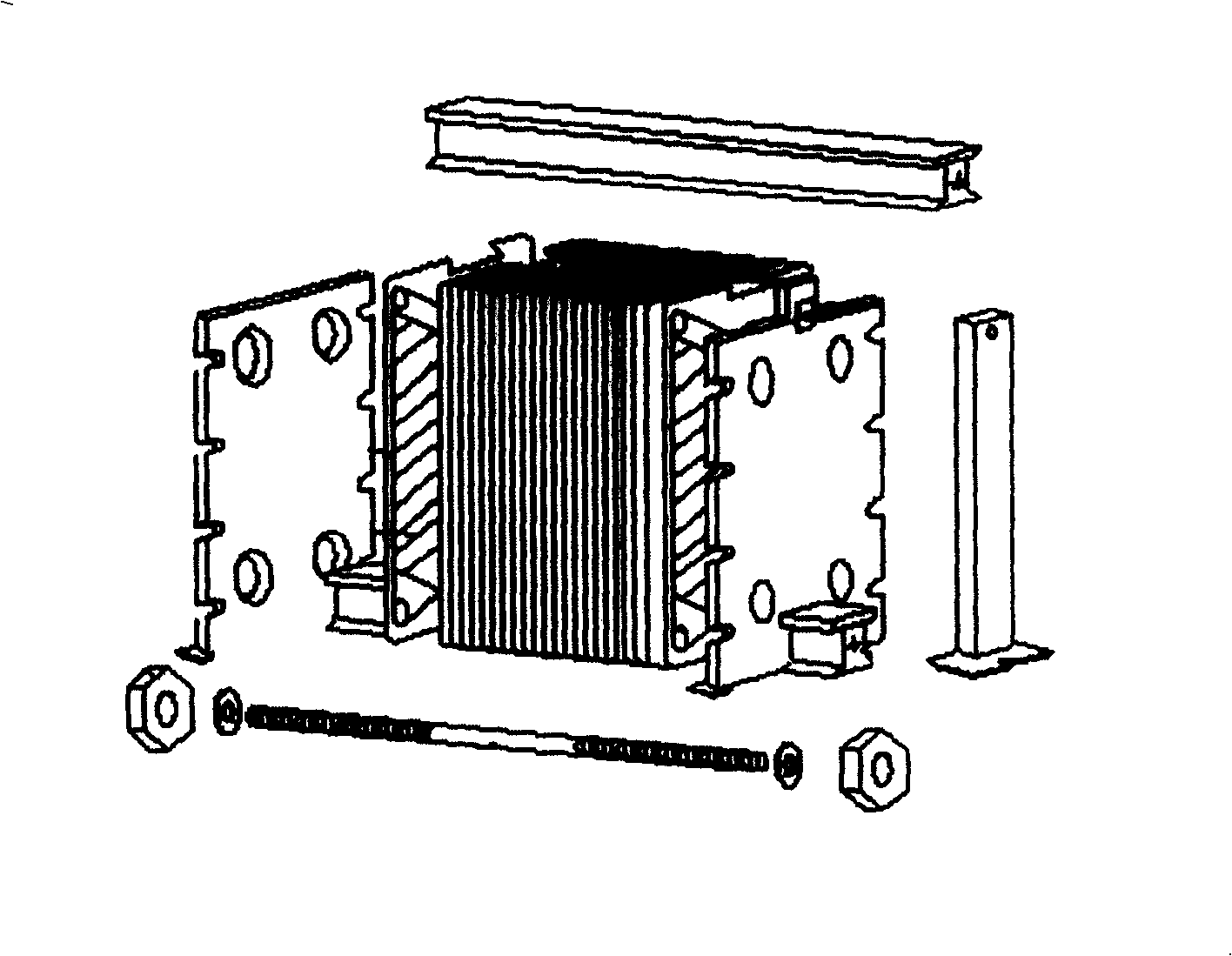

[0038] See figure 1 , The existing plate heat exchanger, because the plate heat exchanger relies on the plate and the plate to be extruded and sealed, and the inverted groove punched by the plate is used as the flow channel, the flow channel gap is small, and the flow is often blocked by small dirt. Therefore, the equipment needs to be cleaned frequently, which affects the heat exchange effect and normal use of the equipment, and causes a lot of inconvenience to users. Moreover, it is a single-stroke, single-flow channel, the thermal efficiency of the equipment is low, energy is wasted, and the operating cost is high.

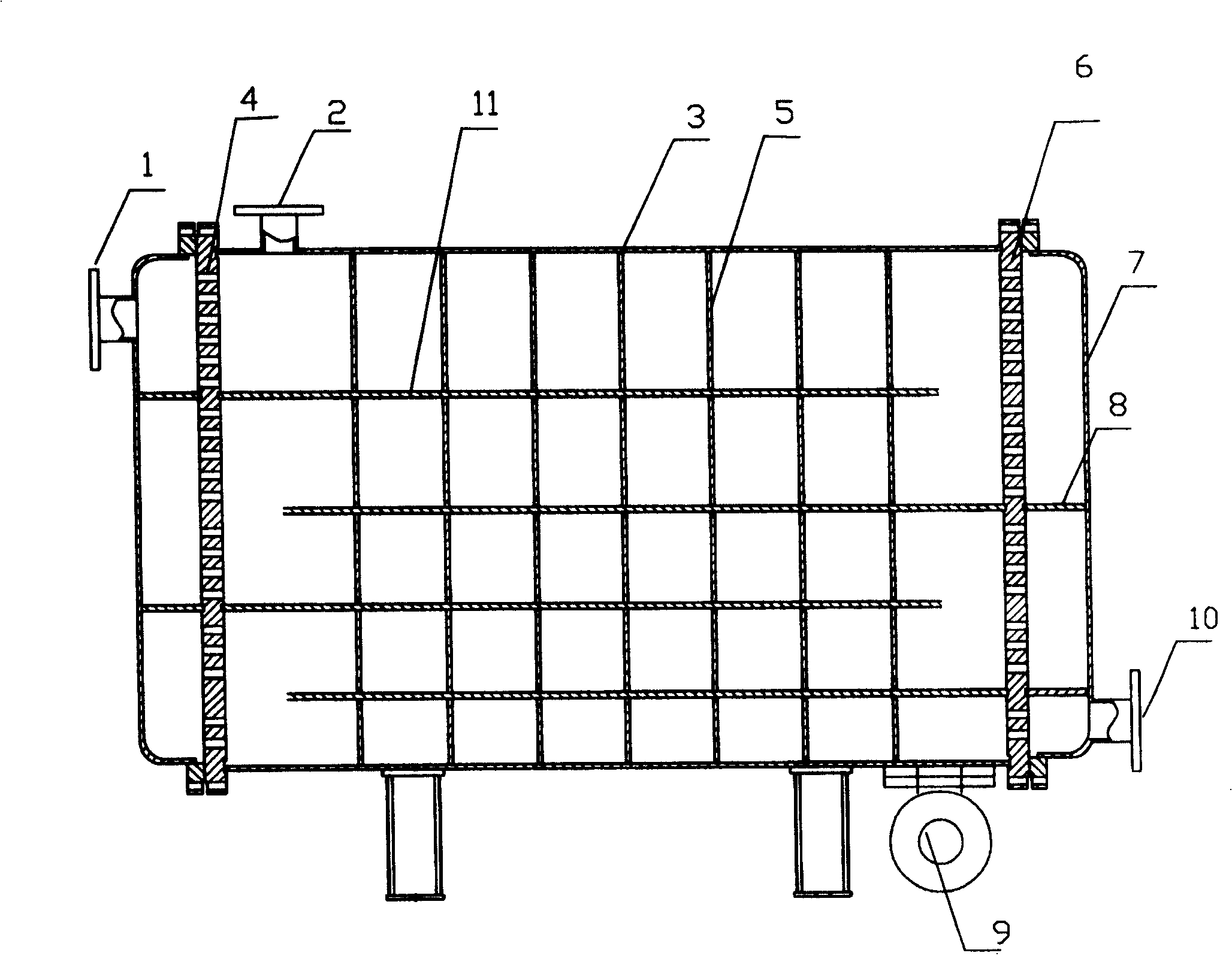

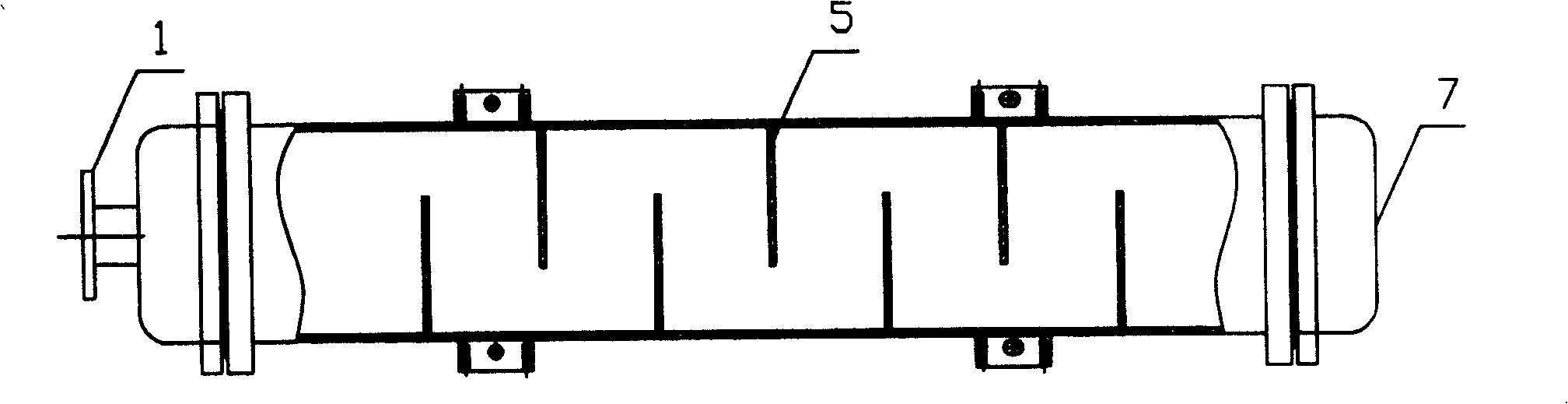

[0039] See figure 2 , image 3 , Figure 4 , The plate-tube return heat exchanger of the present invention is a square box structure, which consists of a square cylinder 3, a plurality of heat exchange tubes 4, a plurality of box baffles 11, and a plurality of tube plate baffles 8. , A plurality of box body baffles 5, square tube plate 6, square flange head 7; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com