Hydrocracking catalyst for Tscher-Topsch synthesis of heavy wax, its preparation method and application thereof

A technology of hydrocracking and Fischer-Tropsch synthesis, applied in the fields of hydrocarbon oil cracking and petroleum industry, which can solve the problems of low activity and cracking activity reduction, and achieve high isomerization selectivity, good selectivity, and good isomerization performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

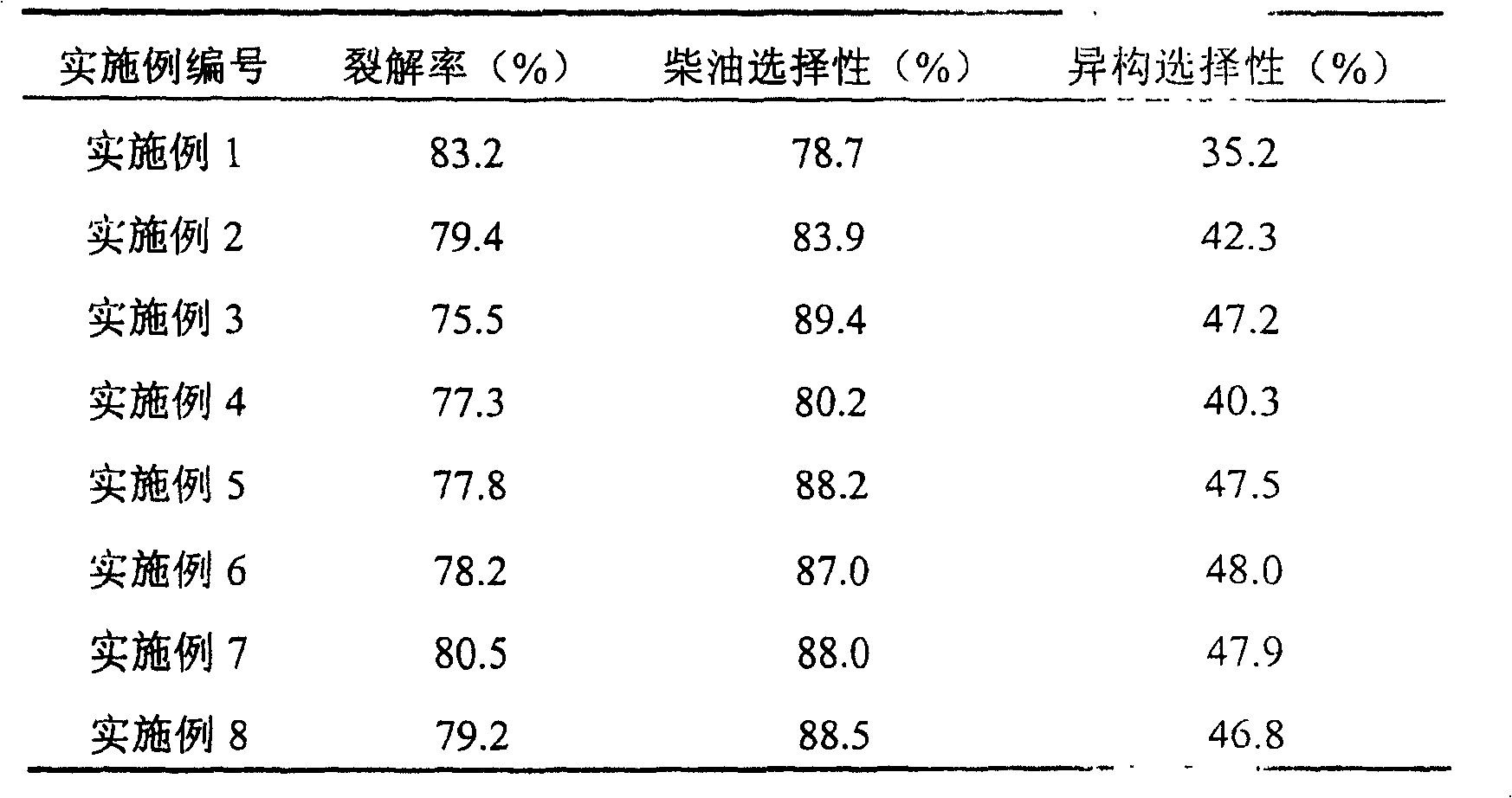

Examples

Embodiment 1

[0028] (1) Weigh 26.0g HY molecular sieve, 13.0g SAPO-11 molecular sieve, 13.0g modified alumina, mix evenly with 48.0g binder pseudo-boehmite, prepare and knead with 5% dilute nitric acid solution , dried in an oven at 100°C for 6h, calcined at 500°C for 6h and then cooled to room temperature to obtain the carrier required by the present invention.

[0029] (2) Using an aqueous solution of nickel nitrate as an impregnating solution, impregnate the solution of nickel nitrate on the formed support, and evaporate the solution to dryness at 100°C. The product was dried at 100°C for 6h, calcined at 500°C for 6h, and then cooled to room temperature to obtain the catalyst involved in the hydrocracking process of the present invention, wherein the mass percentage of each component is composed of: HY type molecular sieve 24.0wt%, 12.0 wt% of SAPO-11 molecular sieve, 12.0 wt% of modified alumina, 44.0 wt% of pseudo-boehmite, and 8.0 wt% of nickel oxide.

[0030] The reaction condition...

Embodiment 2

[0033] (1) Weigh 13.0g HY molecular sieve, 13.0g SAPO-11 molecular sieve, 26.0g amorphous silicon magnesium, mix evenly with 48.0g binder pseudo-boehmite, prepare and knead with 5% dilute nitric acid solution , dried in an oven at 110°C for 5h, calcined at 550°C for 5h and then cooled to room temperature to obtain the carrier required by the present invention.

[0034] (2) Using an aqueous solution of nickel carbonate as an impregnating solution, impregnate the solution of nickel carbonate on the formed support, and evaporate the solution to dryness at 110°C. The product was dried at 110°C for 5h, roasted at 550°C for 5h and then cooled to room temperature to obtain the catalyst involved in the hydrocracking process of the present invention, wherein the mass percentage of each component is composed of: HY type molecular sieve 12.0wt%, 12.0 wt% of SAPO-11 molecular sieve, 24.0 wt% of amorphous silicon magnesium, 44.0 wt% of pseudo-boehmite, and 8.0 wt% of nickel oxide.

[0035...

Embodiment 3

[0038] (1) Weigh 13.0g HY molecular sieve, 26.0g SAPO-11 molecular sieve, 13.0g amorphous silica-alumina, mix with 48.0g binder pseudo-boehmite evenly, prepare with 5% dilute nitric acid solution, knead and form , dried in an oven at 120°C for 4h, calcined at 600°C for 4h and then cooled to room temperature to obtain the carrier required by the present invention.

[0039] (2) Using an aqueous solution of nickel nitrate as an impregnating solution, impregnate the solution of nickel nitrate on the formed carrier, and evaporate the solution to dryness at 120° C. The product was dried at 120°C for 4 hours, calcined at 600°C for 4 hours, and then cooled to room temperature to obtain the catalyst used in the hydrocracking process of the present invention, wherein the mass percentage of each component is: HY type molecular sieve 12.0wt%, 24.0 wt% of SAPO-11 molecular sieve, 12.0 wt% of amorphous silica-alumina, 44.0 wt% of pseudo-boehmite, and 8.0 wt% of nickel oxide.

[0040] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com