Tube sheet friction welding method

A technology of friction welding and tube sheet, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., to achieve the effects of high process stability and reproducibility, high energy utilization rate, and simple mechanical principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

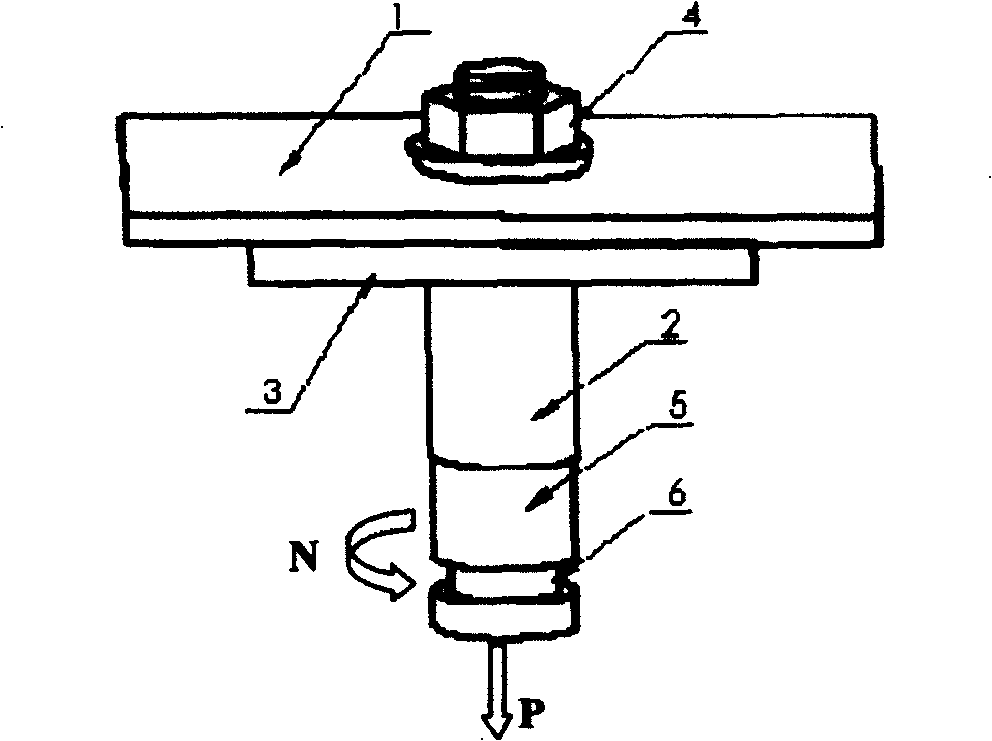

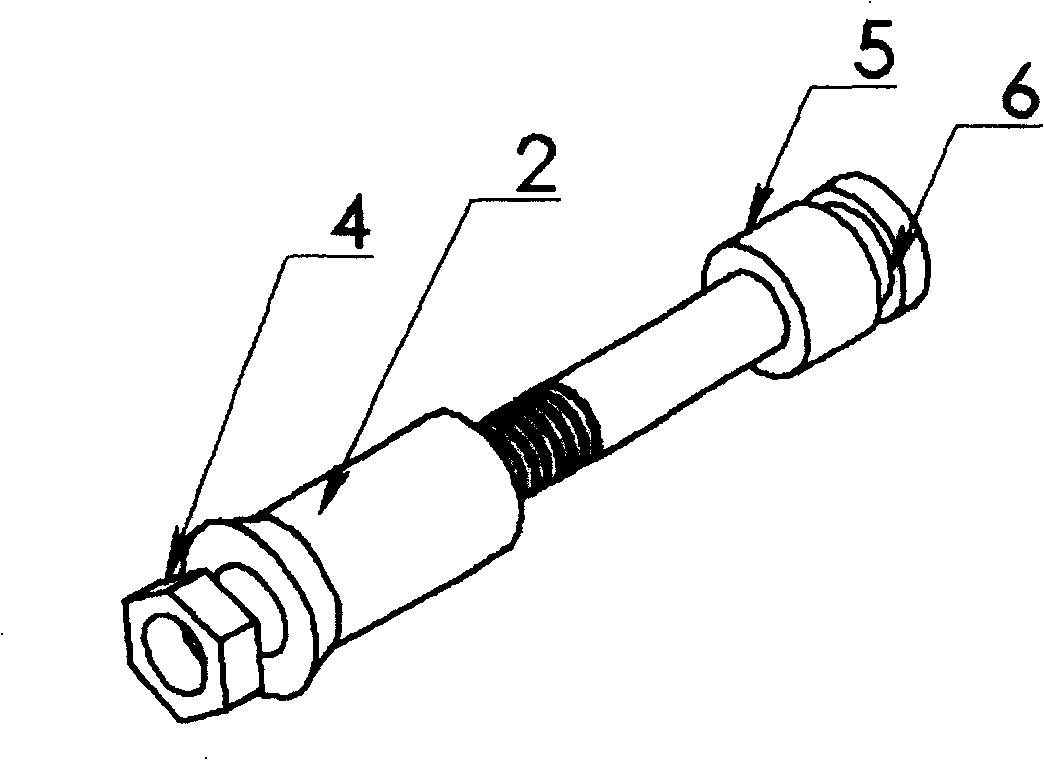

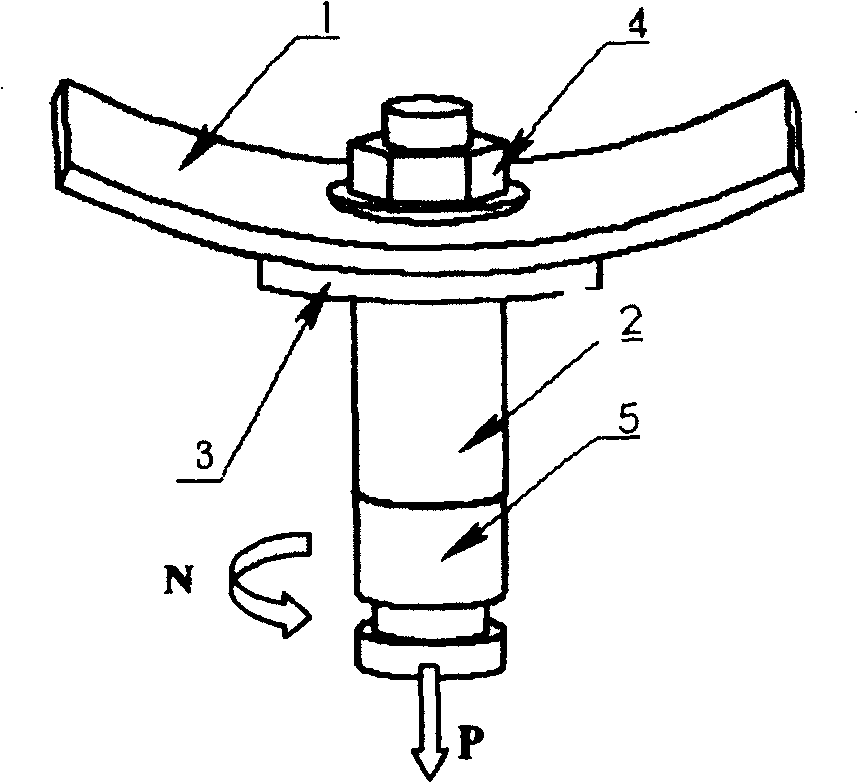

[0024] Such as figure 1 and figure 2 Shown is the first embodiment of the present invention. In the first stage, a hole is processed at the position of the pipe to be welded on the plate 1 to be welded. The shape of the hole is a factor that affects the quality of welding. The hole can be chamfered at full depth or It can be partly chamfered, and the angle of the chamfer can be 10°~30°. The inner diameter D1 of the hole is slightly larger than the outer diameter D2 of the pipe, which is convenient for the pipe to pass through the hole. One end of the pipe 2 should also be processed with a tapered surface. The value range of the angle is 10°~60°, and the outer diameter of the tube D2=12mm~50mm; a backing plate 3 is installed on the back of the wall plate 1; The mandrel 5 and the conduit 2 are fastened together with the nut 4 . The second stage is the friction heating sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com