Harmless treatment process for waste chromium slag

A technology of harmless treatment and process method, applied in the direction of solid waste removal, etc., can solve problems such as harm to farmland and aquatic organisms, carcinogenicity, secondary environmental pollution, etc., and achieve broad prospects for comprehensive utilization, cost reduction, and large disposal volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

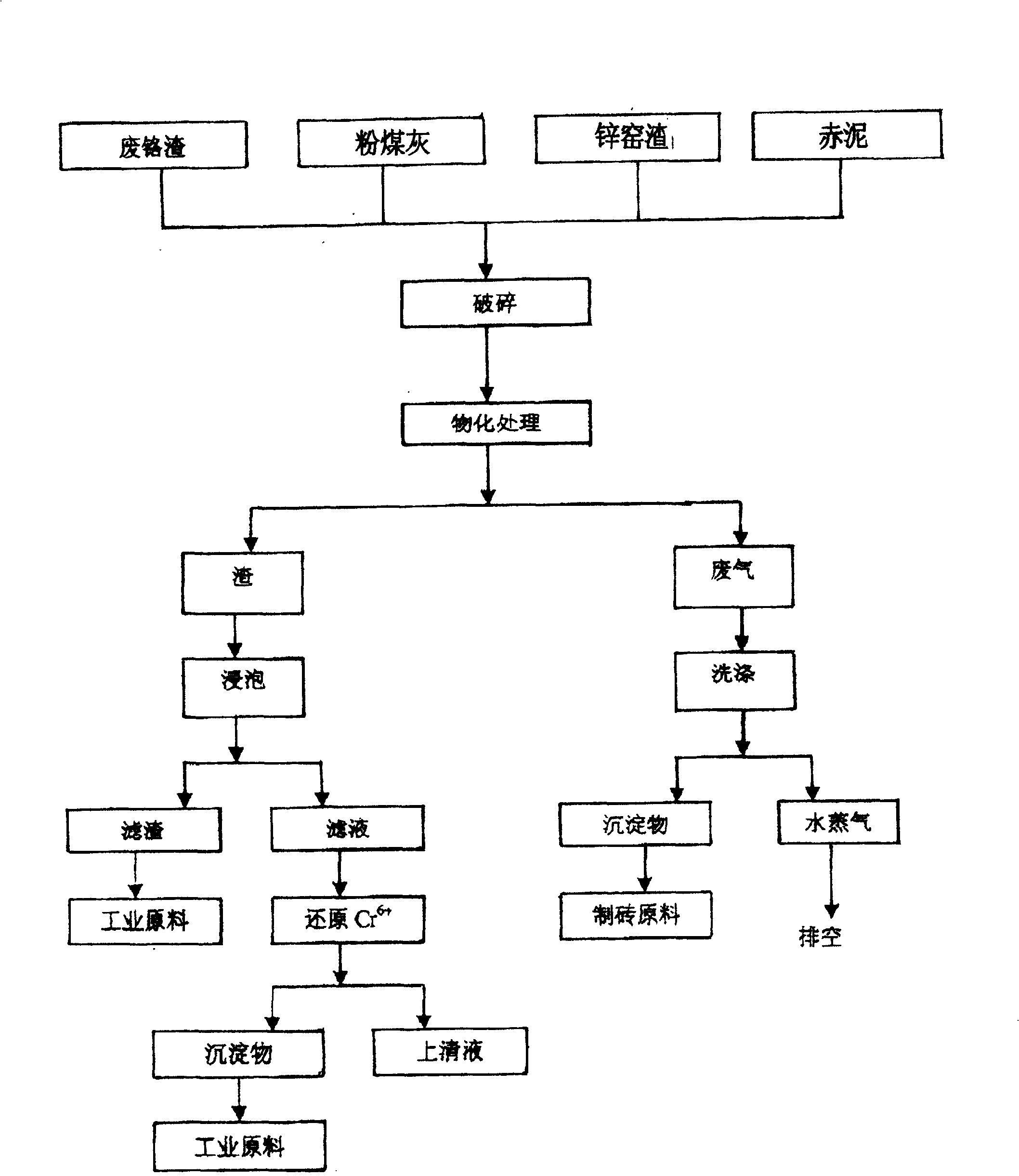

[0013] Embodiment one: if figure 1 , mix 430kg of waste chrome slag with 150kg of fly ash, 120kg of zinc kiln slag, and 300kg of red mud evenly, crush it with a ball mill to 80 mesh fineness, send it to a sintering furnace for physical and chemical treatment, sinter at a high temperature of 1050°C for 3 hours, and then cool it out for 2 hours , the sintered slag was crushed to 50 mesh and soaked in water for 24 hours, then filtered out the slag with a filter cloth, and the filtrate was filtered with FeSO 4 As a reducing agent, FeSO 4 Adding a large amount is fifteen times of the hexavalent chromium ion measured in the filtrate to carry out the reduction reaction, adding FeSO 4 After adjusting the filtrate, under the condition of pH value of 8, the hexavalent chromium ion in the filtrate is reduced to the harmless precipitate of trivalent chromium salt; the waste gas generated during the sintering process is sucked into the washing tower for spray washing, The sediment genera...

Embodiment 2

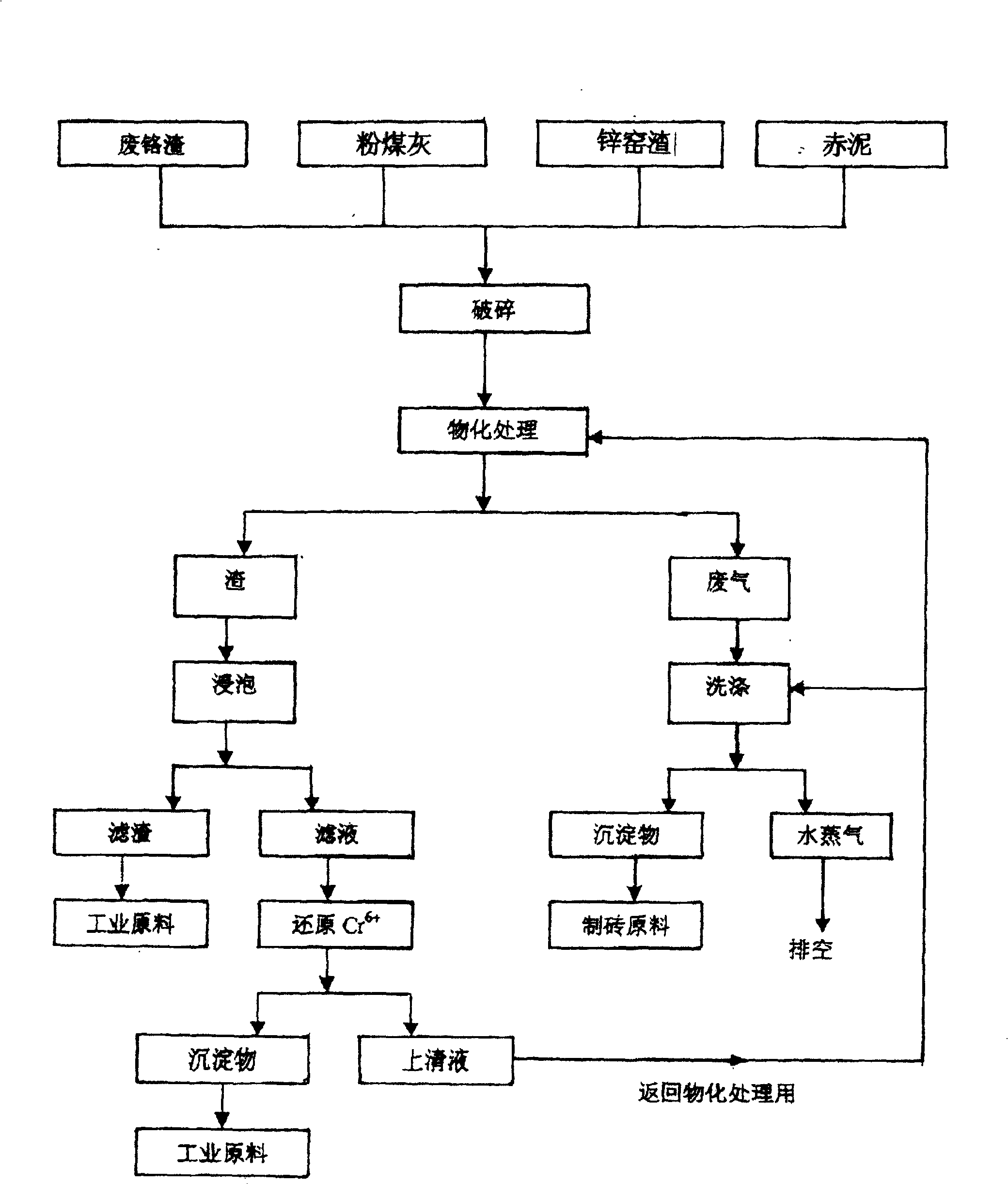

[0014] Embodiment two: see Figure II , mix 450kg waste chrome slag with 100kg fly ash, 150kg zinc kiln slag and 300kg red mud evenly, crush it with a ball mill to 50 mesh fineness, send it to a sintering furnace for physical and chemical treatment, sinter at 1000°C for 4 hours, and then cool it out for 3 hours , the sintered slag was crushed to 50 mesh and soaked in water for 22 hours, then filtered out the slag with a filter cloth, and the filtrate was filtered with FeSO 4 As a reducing agent, FeSO 4 The addition of a large amount is fourteen times of the hexavalent chromium ion measured in the waste chromium slag to carry out the reduction reaction, adding FeSO 4 After adjusting the filtrate, the hexavalent chromium ions in the filtrate are reduced to harmless precipitates of trivalent chromium salts under the condition of pH value of 8.2; the waste gas generated during the sintering process is sucked into the washing tower for spray washing, The sediment generated after ...

Embodiment 3

[0015] Embodiment three: see Figure II , mix 400kg of waste chromium slag with 150kg of fly ash, 150kg of zinc kiln slag, and 300kg of red mud evenly, crush it with a ball mill to a fineness of 60 mesh, send it to a sintering furnace for physical and chemical treatment at 1100°C for 4 hours of high-temperature sintering, and then leave the furnace to cool for 3 hours. The sintered slag was crushed to 50 mesh and soaked in water for 20 hours, then filtered out the slag with a filter cloth, and the filtrate was filtered with FeSO 4 As a reducing agent, FeSO 4 The addition of a large amount is sixteen times of the hexavalent chromium ion measured in the waste chromium slag to carry out the reduction reaction, adding FeSO 4 After adjusting the filtrate, the hexavalent chromium ions in the filtrate are reduced to harmless precipitates of trivalent chromium salts under the condition of pH value of 8.5; the waste gas generated during the sintering process is sucked into the washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com